Method for preparing cage-shaped gold nanoparticles through lanreotide acetate template

A technology of lanreotide acetate and gold nanoparticles, applied in the field of materials, can solve the problems of uneven particle surface voids, low mechanical strength resistance, and uncontrollable morphology, and achieves good reproducibility, good binding condition, Effects that are easy to analyze and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

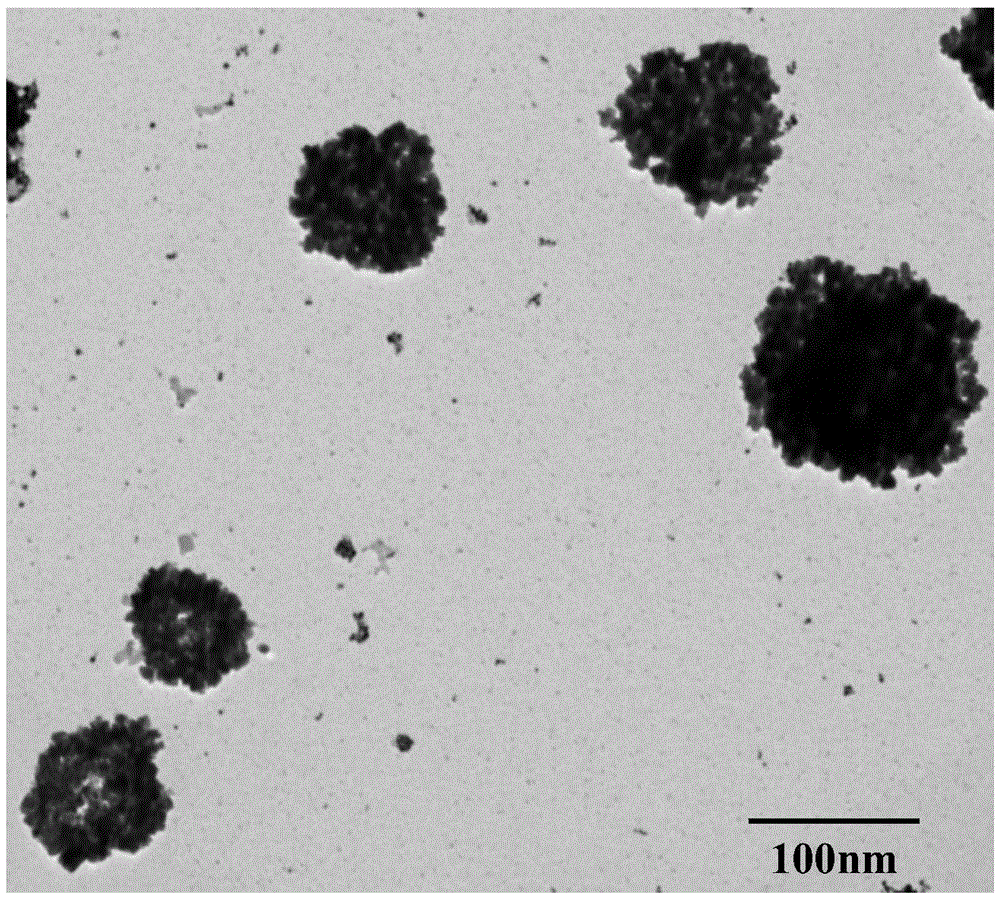

[0020] Take 0.5 mg of lanreotide acetate (manufactured by Wuxi Maimertop Biotechnology Co., Ltd.), and dissolve it in 1 mL of hydrochloric acid solution at pH 2.0 to prepare a lanreotide acetate solution. 20min in the bath, and then ultrasonic treatment for 15s, the ultrasonic frequency is 40Hz; 200μL of lanreotide acetate solution after the metal bath was mixed with 200μL of 2.0mM gold trichloride solution (Tianjin Chemical Reagent Factory) and placed in a water bath constant temperature oscillator Incubate for 16 hours at a control speed of 100 rpm and a temperature of 25°C; finally add 100 μL of 1 mM sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd.) dropwise for reduction, the dropping speed is 2 drops / min, 25 μL / drop , the reaction temperature was 22°C, and the reaction was carried out for 5 minutes, so that it slowly changed from light yellow to blue-purple, that is, lanreotide acetate-caged gold nanoparticles were obtained.

[0021] The mor...

Embodiment 2

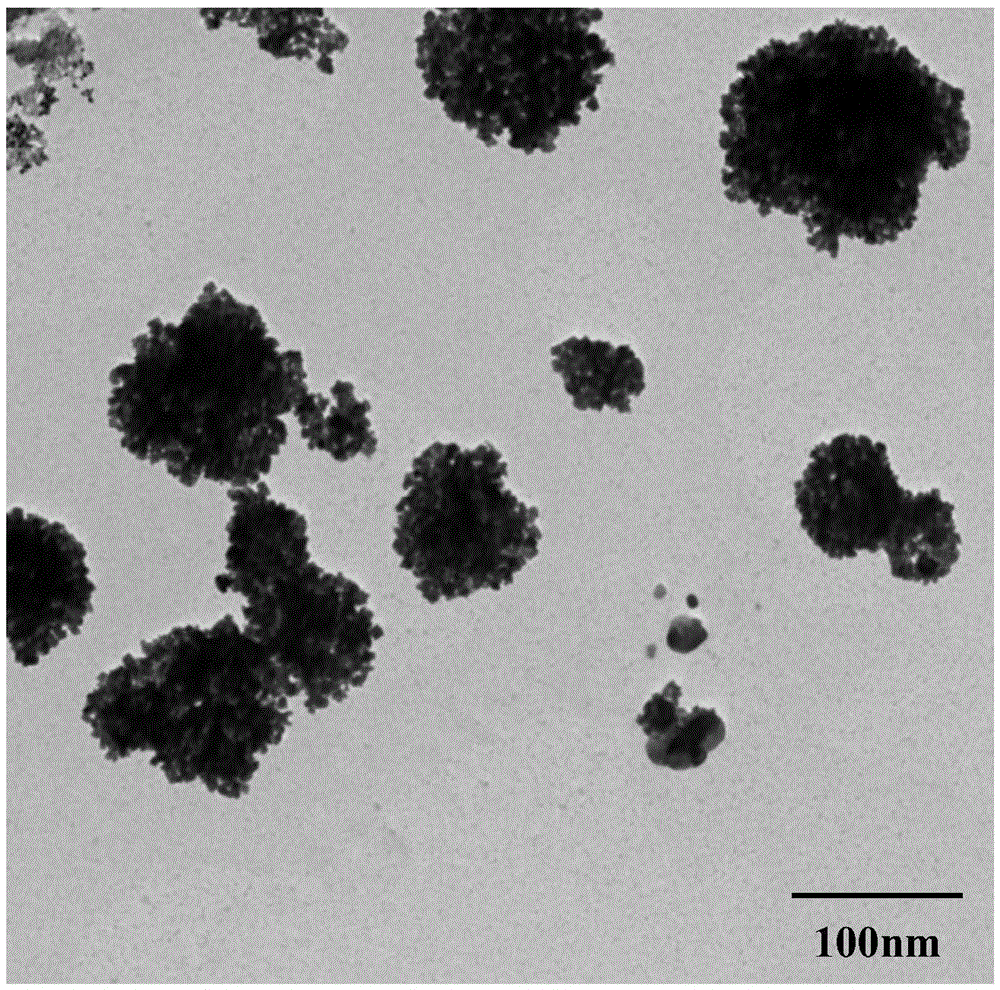

[0023] Take 0.75 mg of lanreotide acetate and dissolve it in 1 mL of hydrochloric acid solution at pH 4.0 to prepare a lanreotide acetate solution. Place the lanreotide acetate solution in a metal bath at 70°C for 30 minutes, and then perform ultrasonic treatment for 15 seconds. 40Hz; take 200μL of lanreotide acetate solution after the metal bath and mix with 200μL of 5.0mM gold trichloride solution, put it into a constant temperature oscillator in a water bath, control the speed at 150rpm, and incubate at 30℃ for 20h; finally drop by drop Add 100 μL of 2.5 mM sodium borohydride for reduction, the dropping rate is 2 drops / min, 25 μL / drop, the reaction temperature is 23°C, and react for 10 minutes, so that it slowly changes from light yellow to blue purple, and the lanreotide acetate-cage is obtained shaped gold nanoparticles.

[0024] The morphology of caged gold nanoparticles was characterized by transmission electron microscopy, such as figure 2 As shown, the diameter of t...

Embodiment 3

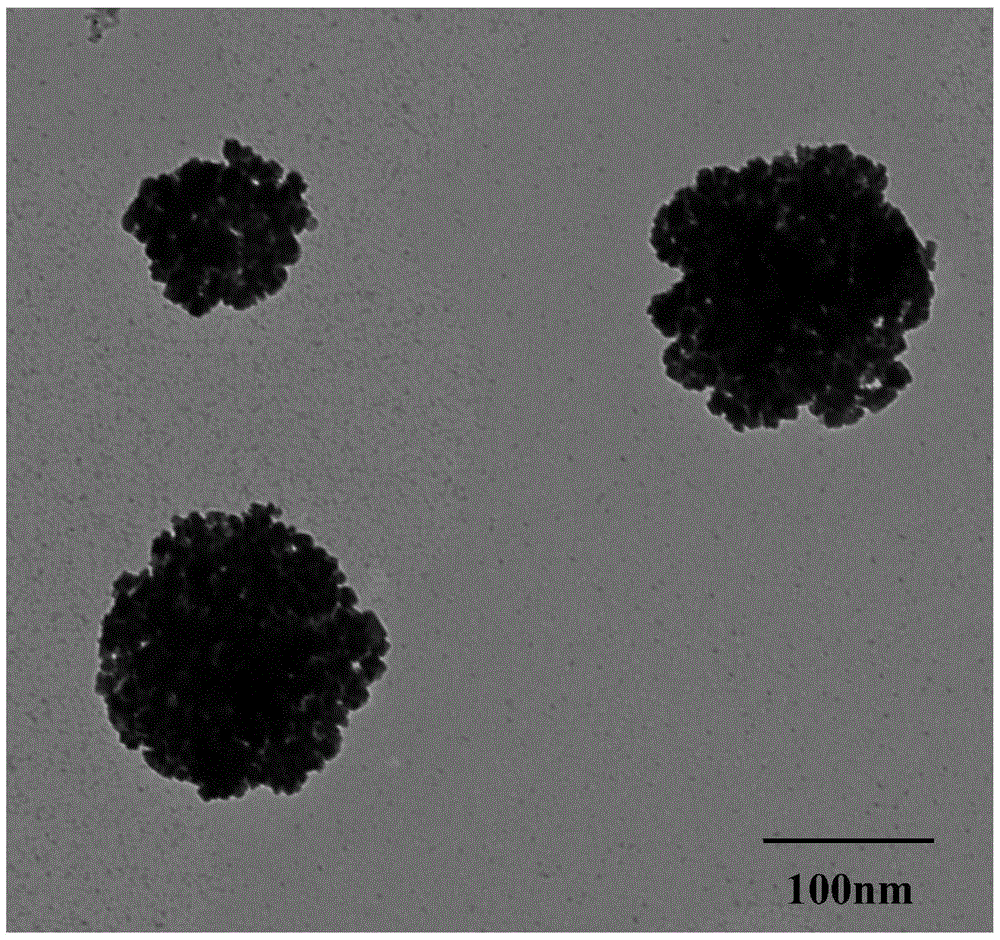

[0026] Take 1.0 mg of lanreotide acetate and dissolve it in 1 mL of hydrochloric acid solution at pH 6.0 to prepare a lanreotide acetate solution. Place the lanreotide acetate solution in a metal bath at 70°C for 40 minutes, and then perform ultrasonic treatment for 15 seconds. 40Hz; take 200μL of lanreotide acetate solution after the metal bath and mix with 200μL of 7.0mM gold trichloride solution, put it into a constant temperature oscillator in a water bath, control the rotation speed at 130rpm, and incubate at 30℃ for 24h; finally drop by drop Add 100 μL of 5.0 mM sodium borohydride for reduction, the dropping rate is 2 drops / min, 25 μL / drop, the reaction temperature is 25°C, and react for 15 minutes, so that it slowly changes from light yellow to blue purple, and the lanreotide acetate-cage is obtained shaped gold nanoparticles.

[0027] The morphology of caged gold nanoparticles was characterized by transmission electron microscopy, such as image 3 As shown, the diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com