A kind of polymer modified asphalt concrete

A technology for modifying asphalt and polymers, which is applied in the field of asphalt concrete and polymer-modified asphalt concrete to achieve the effects of improving aging resistance and water resistance, increasing road surface temperature, and non-toxic and harmless raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

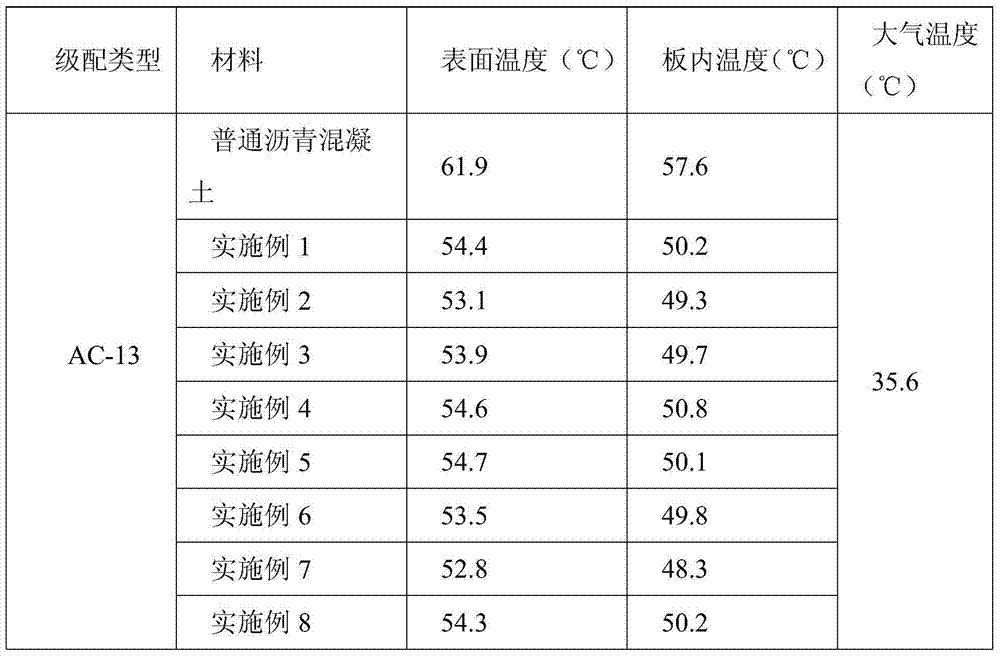

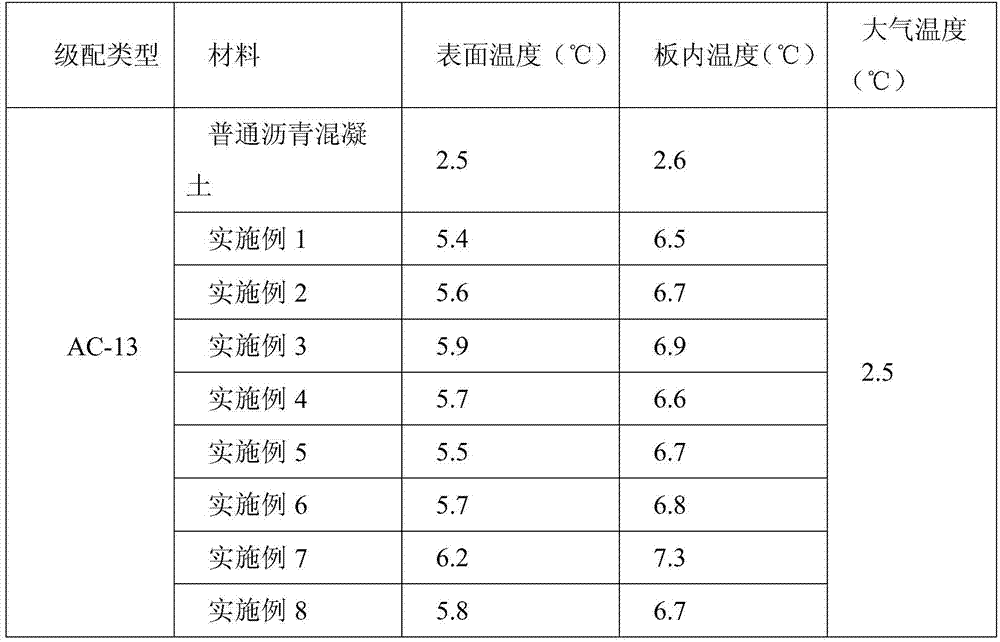

Examples

Embodiment 1

[0025] This example provides a kind of polymer modified asphalt concrete, which is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 3 parts of asphalt, 0.2 part of polymer, 0.01 part of improver, 0.01 part of stabilizer, Coupling agent 0.001 part; The ore material that present embodiment adopts is AC-13 type ore material, and the coupling agent that adopts is gamma-(methacryloyl oxygen) propyl trimethoxysilane, and the asphalt that adopts is SBS asphalt.

[0026] The preparation method of polymer modified asphalt concrete in this embodiment comprises the following steps:

[0027] Step 1. Prepare the modifier: weigh the polymer, improver, and coupling agent and mix them evenly to obtain the modifier; in the specific preparation process, the coupling agent can be diluted with ethanol first, and then the polymer and improver Add the mixture of the coupling agent to the diluent of the coupling agent, stir it thoroughly, and then place it in ...

Embodiment 2

[0031] This embodiment provides a polymer modified asphalt concrete, which is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 4.5 parts of asphalt, 0.8 part of polymer, 0.08 part of improver, 0.08 part of stabilizer, 0.02 part of coupling agent; the mineral material adopted in the present embodiment is AC-13 type mineral material, and the coupling agent adopted is gamma-(methacryloyl oxygen) propyltrimethoxysilane, and the asphalt adopted is coal tar pitch.

[0032] The preparation method of polymer modified asphalt concrete in this embodiment comprises the following steps:

[0033] Step 1. Prepare the modifier: weigh the polymer, improver, and coupling agent and mix them evenly to obtain the modifier; in the specific preparation process, the coupling agent can be diluted with ethanol first, and then the polymer and improver Add the mixture of the coupling agent to the diluent of the coupling agent, stir it thoroughly, and then place it...

Embodiment 3

[0037] This embodiment provides a polymer modified asphalt concrete, which is made of the following raw materials in parts by weight: 100 parts of mineral aggregate, 5.5 parts of asphalt, 1.2 parts of polymer, 0.15 part of improver, 0.15 part of stabilizer, 0.05 part of coupling agent; the mineral material adopted in the present embodiment is AC-13 type mineral material, and the coupling agent adopted is gamma-(methacryloyl oxygen) propyltrimethoxysilane, and the asphalt adopted is Road petroleum asphalt.

[0038] The preparation method of polymer modified asphalt concrete in this embodiment comprises the following steps:

[0039] Step 1. Prepare the modifier: weigh the polymer, improver, and coupling agent and mix them evenly to obtain the modifier; in the specific preparation process, the coupling agent can be diluted with ethanol first, and then the polymer and improver Add the mixture of the coupling agent to the diluent of the coupling agent, stir it thoroughly, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com