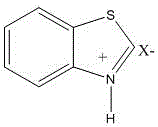

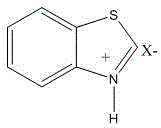

Benzothiazole ionic liquid and preparation method as well as application thereof

An ionic liquid and benzothiazole technology, applied in the field of ionic liquid catalysts, can solve the problems such as low price of Bronsted acid functionalized ionic liquid, and achieve the effects of easy recycling, convenient recovery and high catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add a solution of 6.75g (50nmol) of benzothiazole in 25mL of absolute ethanol to the reaction flask, and add H2 dropwise within 30min at 0-5°C under full stirring. 2 SO 4 12.08g (55nmol) of ethanol solution in 10mL, react at room temperature for 3h after dropping. The solvent was evaporated, the residue was washed with ethyl acetate (3×5 mL), and then recrystallized from absolute ethanol to obtain the product as a white crystalline solid, benzothiazole thiohydrogen salt ionic liquid. The yield was 98.4%.

Embodiment 2

[0017] Add 6.75g (50nmol) of benzothiazole in 25mL of absolute ethanol solution in the reaction flask, and add HCLO dropwise at 0-5°C within 30min under full stirring. 4 7.85g (55nmol) of 70% aqueous solution was reacted at room temperature for 3h after dripping. The solvent was evaporated, the residue was washed with ethyl acetate (3×5 mL), and recrystallized from absolute ethanol to obtain a white powder, benzothiazole perchlorate ionic liquid. The calculated yield was 98.6%.

Embodiment 3

[0019] Add 6.75g (50nmol) of benzothiazole in 25mL of absolute ethanol solution in the reaction bottle, add dropwise 12.08g (55nmol) of phosphoric acid in 10mL of ethanol solution at 0-5°C within 30min under full stirring, Reaction 3h. The solvent was evaporated, the residue was washed with ethyl acetate (3×5 mL), and recrystallized from absolute ethanol to obtain the product benzothiazole dihydrogen phosphate ionic liquid. The calculated yield was 96.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com