Liquid phase method for epitaxial growth of MoSe2-XnSem heterogeneous nano structures

A mose2-xnsem and nanostructure technology, applied in liquid phase epitaxial layer growth, crystal growth, single crystal growth, etc., to achieve the effect of reducing cost, reducing reaction temperature, and shortening growth time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

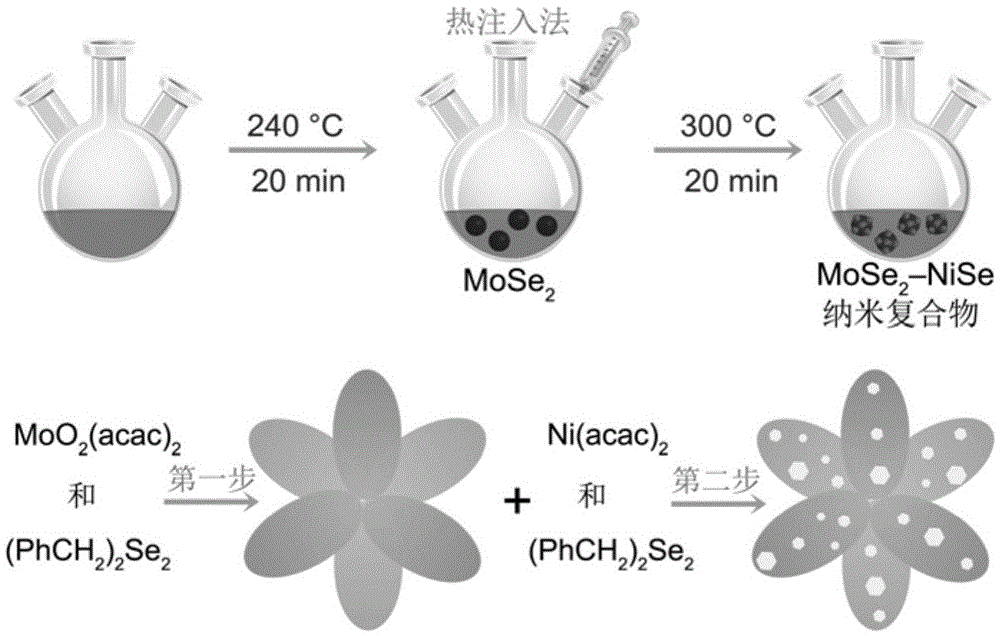

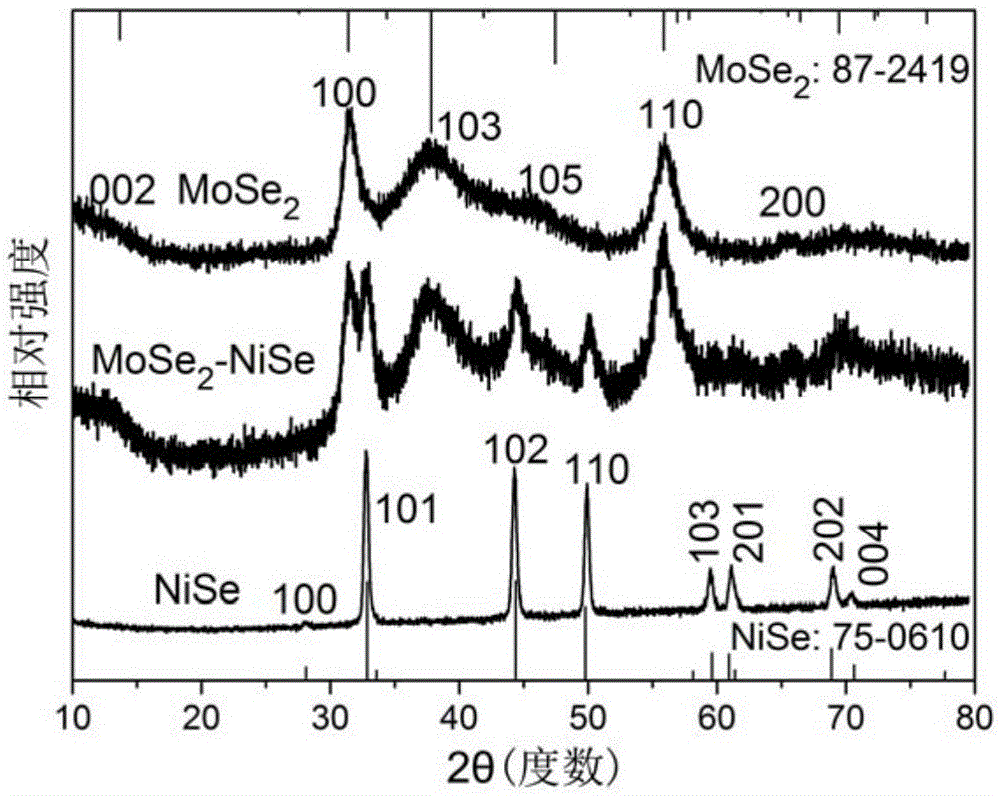

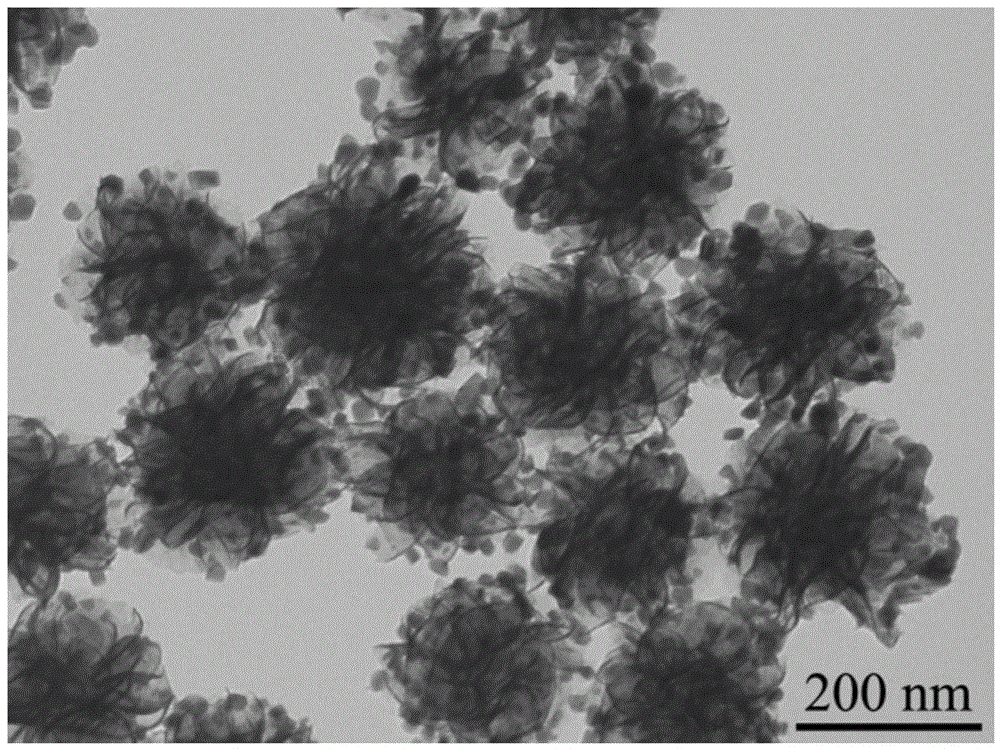

[0043] This example prepares MoSe according to the following steps 2 -NiSe hetero-nanostructure:

[0044] like figure 1 As shown, weigh 0.0326g (0.1mmol) oxymolybdenum acetylacetonate, 0.0340g (0.1mmol) dibenzyl diselenide, measure 6mL oleylamine, and carefully transfer them to the bottom of a 50mL three-necked flask A, and then pass into Argon, add high-temperature magnets to stir, heat the reactant to 130°C for 30min to remove water and other low-boiling impurities. Through temperature programming, the temperature was raised to 250° C. at a rate of 10° C. per minute, and continued to rise to 300° C. after 20 minutes of reaction.

[0045] During this period, weigh 0.0257 g (0.1 mmol) nickel acetylacetonate, 0.0170 g (0.05 mmol) dibenzyl diselenide, measure 0.5 mL oleylamine, and transfer them carefully to a 5 mL centrifuge tube B for ultrasonic dissolution Then put it in an oven at 70°C for later use.

[0046] When the temperature of the three-neck flask A was raised to 3...

Embodiment 2

[0054] Weigh 0.0326g (0.1mmol) oxymolybdenum acetylacetonate, 0.0340g (0.1mmol) dibenzyl diselenide, measure 6mL oleylamine, and carefully transfer them to the bottom of a 50mL three-necked flask A, and then feed argon, Add a high-temperature magnet to stir, and heat the reactant to 130°C for 30 minutes to remove moisture and other low-boiling impurities. Through temperature programming, the temperature was raised to 230°C at a rate of 10°C per minute, and the temperature was lowered to 200°C after 360 minutes of reaction.

[0055] During this period, weigh 0.0052 g (0.02 mmol) nickel acetylacetonate, 0.0034 g (0.01 mmol) dibenzyl diselenide, measure 0.5 mL oleylamine, and transfer them carefully to a 5 mL centrifuge tube B for ultrasonic dissolution Then put it in an oven at 70°C for later use.

[0056] When the temperature of the three-neck flask A dropped to 200°C, extract 0.5mL of the solution in the centrifuge tube B and quickly inject it into A, and keep it at 200°C for...

Embodiment 3

[0058] Weigh 0.0326g (0.1mmol) oxymolybdenum acetylacetonate, 0.0340g (0.1mmol) dibenzyl diselenide, measure 6mL oleylamine, and carefully transfer them to the bottom of a 50mL three-necked flask A, and then feed argon, Add a high-temperature magnet to stir, and heat the reactant to 130°C for 30 minutes to remove moisture and other low-boiling impurities. Through temperature programming, the temperature was raised to 320° C. at a rate of 10° C. per minute, and reacted for 5 minutes.

[0059] During this period, weigh 0.0196 g (0.06 mmol) nickel acetylacetonate, 0.0102 g (0.03 mmol) dibenzyl diselenide, measure 0.5 mL oleylamine, and transfer them carefully to a 5 mL centrifuge tube B for ultrasonic dissolution Then put it in an oven at 70°C for later use.

[0060]After the three-neck flask A reacted for 5 minutes, extract 0.5 mL of the solution in the centrifuge tube B and quickly inject it into A, and keep the reaction at 320°C for 5 minutes. After the reaction was finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com