Cheap disorder broad-spectrum wide-angle antireflection structure and manufacturing method thereof

A production method and wide-spectrum technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of easy to improve battery cost performance, high price, high preparation process, etc., to improve photoelectric conversion efficiency and Other properties, the effect of simple preparation scheme and compatible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Deposit a dielectric film on the surface of the substrate material

[0048] SiO with a thickness of 520nm is deposited on the Si substrate by PECVD to form a dielectric film.

[0049] 2. Preparation of metal colloid solution (3.75%Ag)

[0050] The metal-organic colloid solution was prepared at a dilution ratio of 70% Agink: ethanol = 1:18.

[0051] 3. Preparation of metal colloid film

[0052] A metal film layer with a thickness of 140 nm was obtained on the dielectric film by a spin coating method.

[0053] 4. Preparation of metal nanostructures

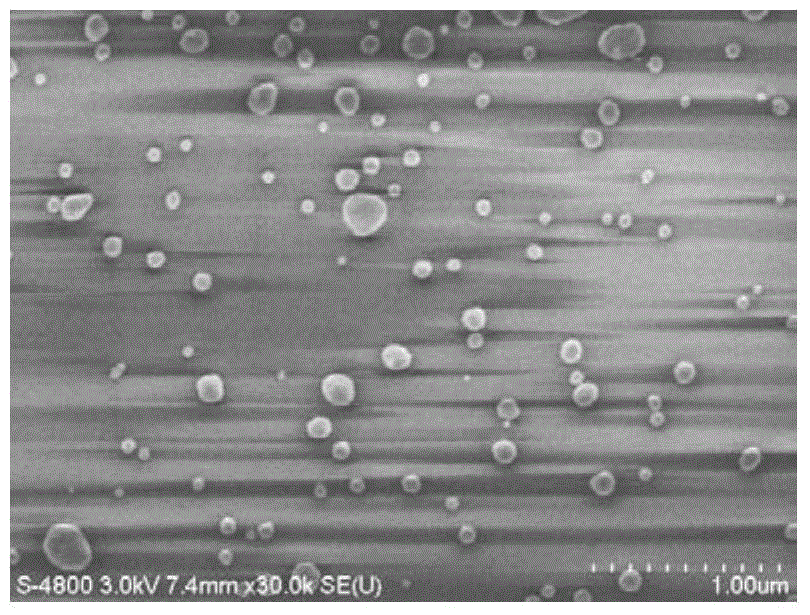

[0054] Metal nanostructures were obtained by heating at 280°C for 5 minutes by means of hot plate heating. figure 1 shown.

[0055] 5. Fabrication of anti-reflection structure

[0056] Using reactive ion etching, using SF 6 / CHF 3 / He three etching gases were etched for 2.5 minutes, and the etching depth was about 490 nm, and an anti-reflection structure with a disordered wide spectrum and wide angle was obtained. ...

Embodiment 2

[0059] 1. Deposit a dielectric film on the surface of the substrate material

[0060] SiO with a thickness of 520nm is deposited on the Si substrate by PECVD to form a dielectric film.

[0061] 2. Preparation of metal colloid solution (7.00%Ag)

[0062] The metal colloid solution was prepared at a dilution ratio of 70% Agink: ethanol = 1:9.

[0063] 3. Preparation of metal colloid film

[0064] A 220nm metal film layer was obtained on the dielectric film by a spin coating method.

[0065] 4. Preparation of metal nanostructures

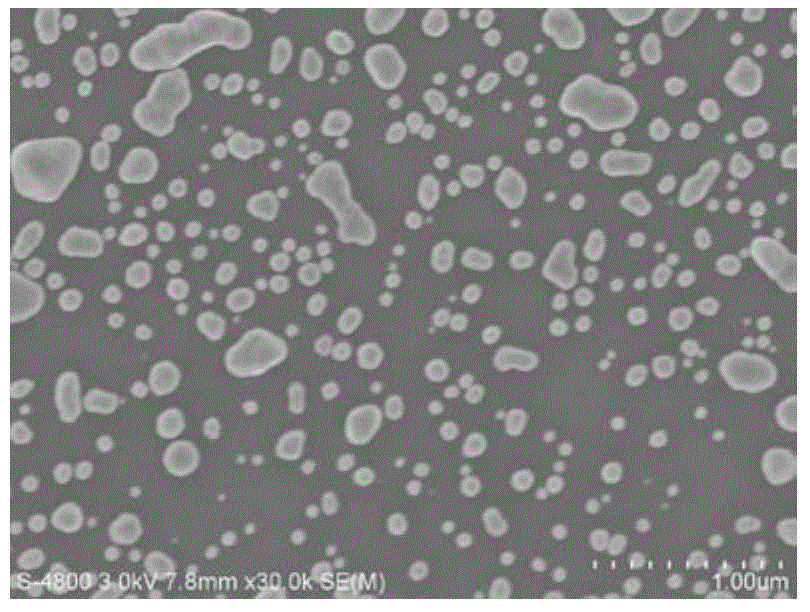

[0066] Metal nanostructures were obtained by heating at 350°C for 2 minutes by means of hot plate heating. figure 2 shown.

[0067] 5. Fabrication of anti-reflection structure

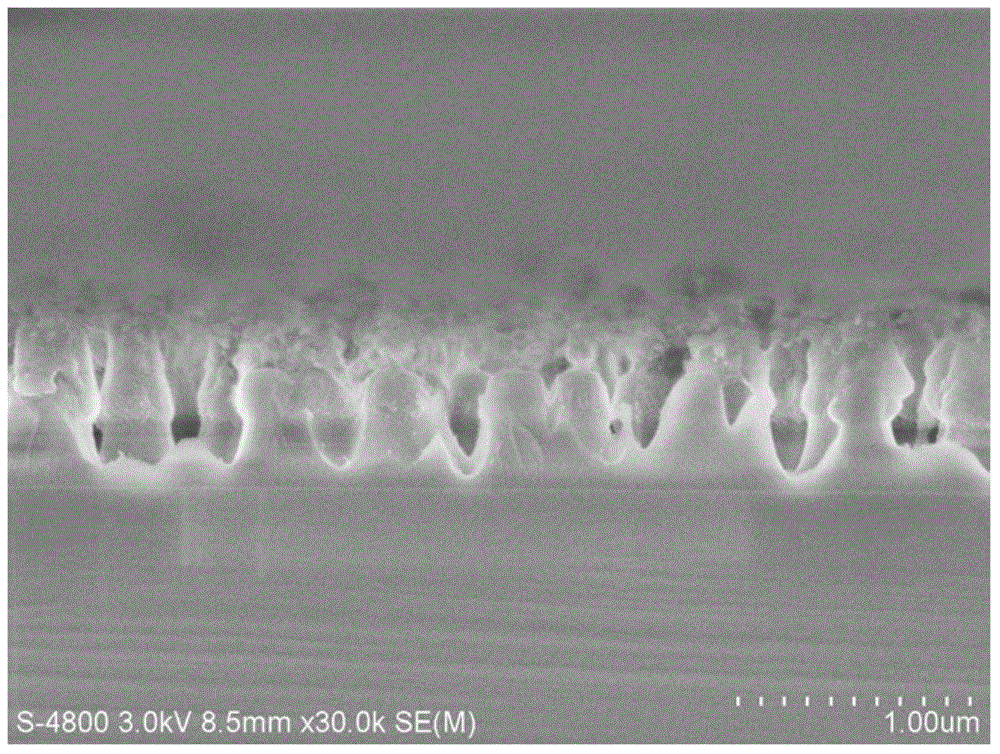

[0068] Using reactive ion etching, using SF 6 / CHF 3 / He three etching gases etch for 2.5min, and the etching depth is about 490nm, and the anti-reflection structure with disordered wide spectrum and wide angle is obtained. image 3 shown.

[0069] The metal nanostru...

Embodiment 3

[0071] 1. Deposit a dielectric film on the surface of the substrate material

[0072] SiO with a thickness of 520nm is deposited on the Si substrate by PECVD to form a dielectric film.

[0073] 2. Preparation of metal colloid solution (8.75%Ag)

[0074] The metal colloid solution was prepared with a dilution ratio of 70% Agink: ethanol = 1:7.

[0075] 3. Preparation of metal colloid film

[0076] A 260nm metal film layer was obtained on the dielectric film by a spin coating method.

[0077] 4. Preparation of metal nanostructures

[0078] Metal nanostructures were obtained by heating at 200°C for 10 minutes by means of hot plate heating. Figure 4 shown.

[0079] 5. Fabrication of anti-reflection structure

[0080] Using reactive ion etching, using SF 6 / CHF 3 / He three etching gases were etched for 2.5 minutes, and the etching depth was about 490 nm, and an anti-reflection structure with a disordered wide spectrum and wide angle was obtained.

[0081] The metal nanost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com