A kind of preparation method of fiber reinforced silicon carbide ceramic matrix composite material

A technology of silicon carbide ceramic matrix and composite materials, which is applied in the field of ceramic matrix composite materials and ceramic matrix composite materials for space optical systems. Efficiency reduction and other issues, to achieve the effect of shortening the densification cycle, reducing the difficulty of processing, and reducing the coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

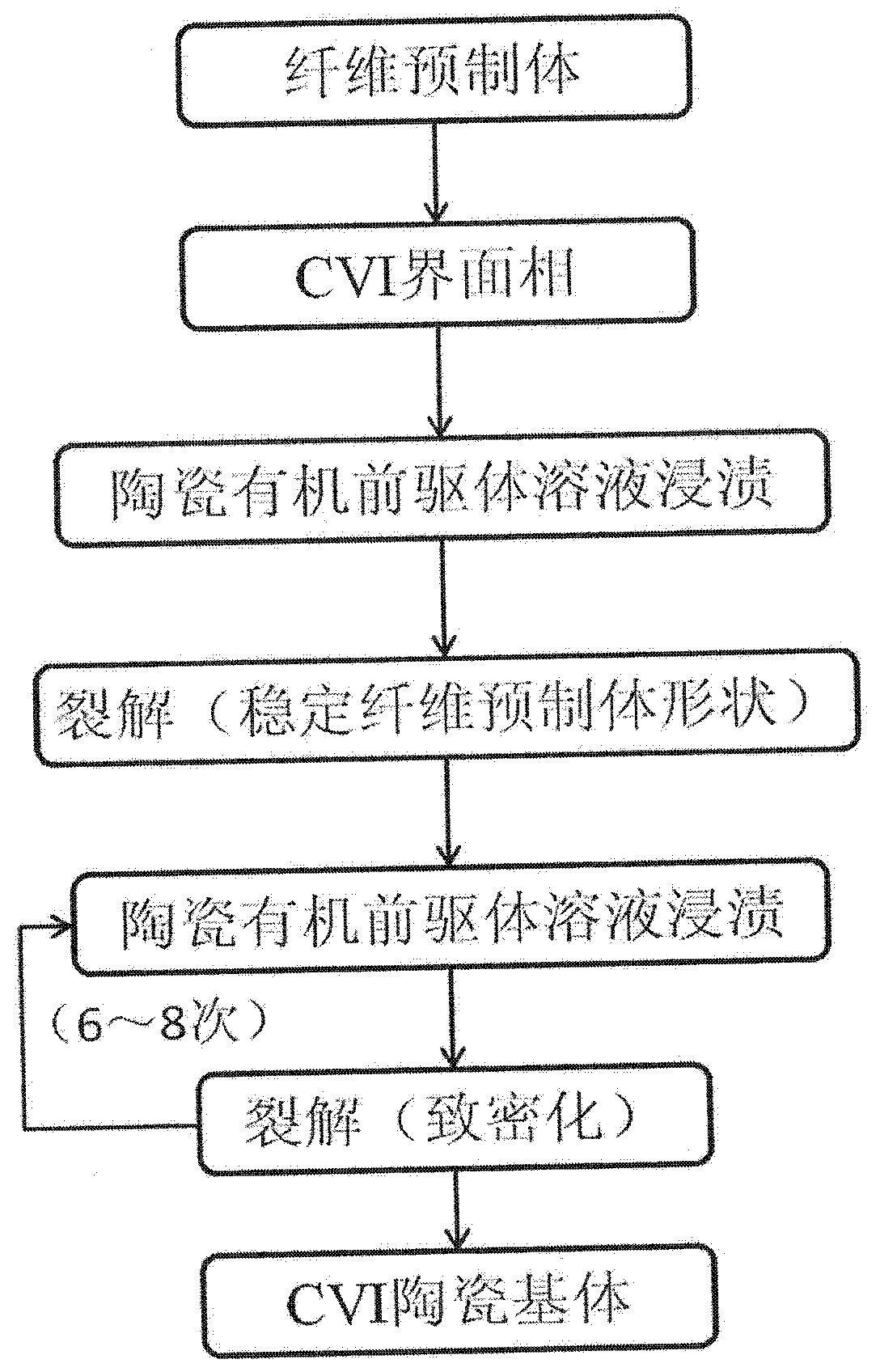

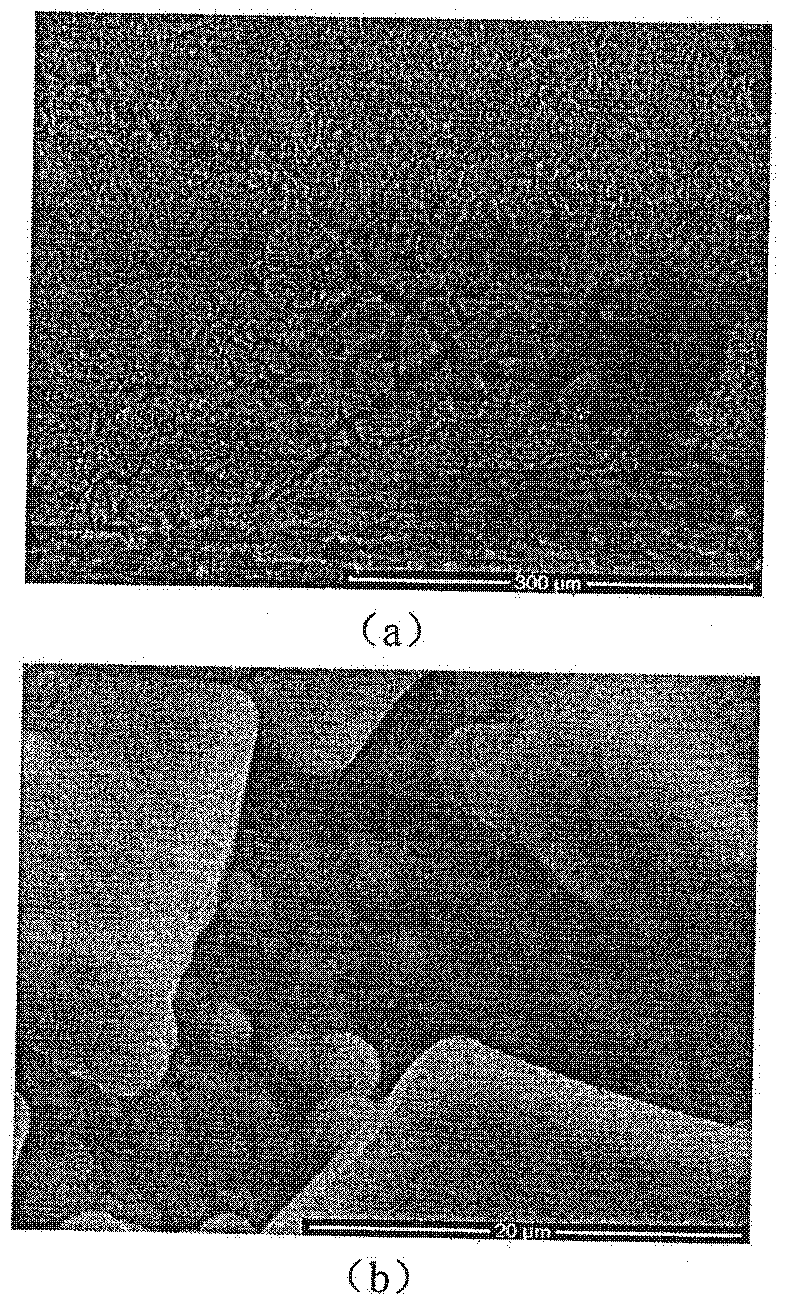

[0032] Such as figure 1 As shown, a layer of PyC continuous interfacial phase was prepared on the fiber surface of the flat three-dimensional braided carbon fiber preform by CVI, the total thickness of the interfacial phase was 100nm, and then its shape was fixed by graphite tooling, impregnated with polycarbosilane (PCS) Toluene solution; after drying, the impregnated organic precursor is cracked in a vacuum furnace and converted into a ceramic matrix at a cracking temperature of 900 ° C. After removing the tooling, a flat workpiece is obtained; again impregnated with a xylene solution of polycarbosilane (PCS) , after drying, it was cracked in a vacuum furnace at 900 ° C. After repeating the impregnation-cracking process 7 times, the obtained flat workpiece was transferred to a CVI furnace, and SiC was prepared by CVI for further densification. The specific process parameters are: deposition temperature The temperature is 960°C, the deposition pressure is 1kPa, the flow rate ...

Embodiment 2

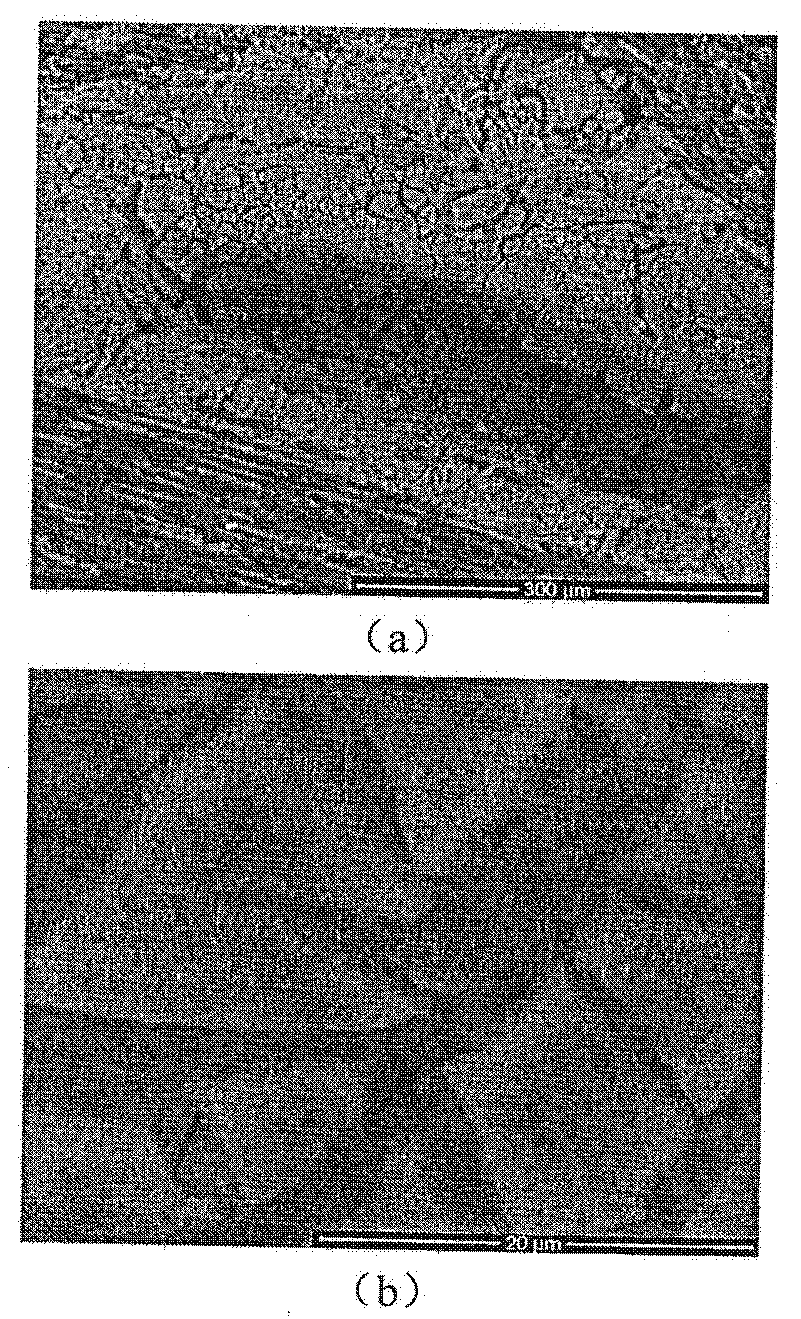

[0040]Using CVI to prepare a layer of PyC continuous interface phase on the fiber surface of the flat three-dimensional braided carbon fiber preform, the total thickness of the interface phase is 130nm, and then use graphite tooling to fix its shape and impregnate polycarbosilane (PCS) xylene solution; After drying, crack the impregnated organic precursor in a vacuum furnace and convert it into a ceramic matrix. The cracking temperature is 900°C. Crack in a vacuum furnace at 900°C. After repeating the impregnation-cracking process 7 times, transfer the obtained flat workpiece to a CVI furnace, and use CVI to prepare SiC for further densification. The specific process parameters are: the deposition temperature is 960°C , the deposition pressure is 1kPa, the flow rate of Ar gas is 5L / min, the flow rate of hydrogen gas is 5L / min, the flow rate of trichloromethylsilane is 1L / min, and the deposition time is 34h.

[0041] The bending strength of the three-dimensional carbon fiber re...

Embodiment 3

[0043] Using CVI to prepare a layer of PyC / SiC continuous interface phase on the fiber surface of the flat three-dimensional braided carbon fiber preform, the total thickness of the interface phase is 130nm, and then use graphite tooling to fix its shape and impregnate polycarbosilane (PCS) in xylene solution; after drying, the impregnated organic precursor is cracked in a vacuum furnace and converted into a ceramic matrix at a cracking temperature of 900 ° C. After removing the tooling, a flat workpiece is obtained; again, the xylene solution of polycarbosilane (PCS) is impregnated, After drying, it was cracked in a vacuum furnace at 900 ° C. After repeating the impregnation-cracking process 7 times, the obtained flat workpiece was transferred to a CVI furnace, and SiC was prepared by CVI for further densification. The specific process parameters are: the deposition temperature is 960°C, the deposition pressure is 1kPa, the flow rate of Ar gas is 5L / min, the flow rate of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com