Indium-sulfide mesoporous hollow microsphere photocatalyst, and preparation method and uses thereof

A technology of indium sulfide mesoporous and photocatalyst, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the influence of photocatalytic degradation efficiency of catalysts, have not yet discovered hollow microsphere nanomaterials, synthesized Expensive and other issues, to achieve excellent photocatalytic activity, reduce energy consumption and reaction costs, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 21

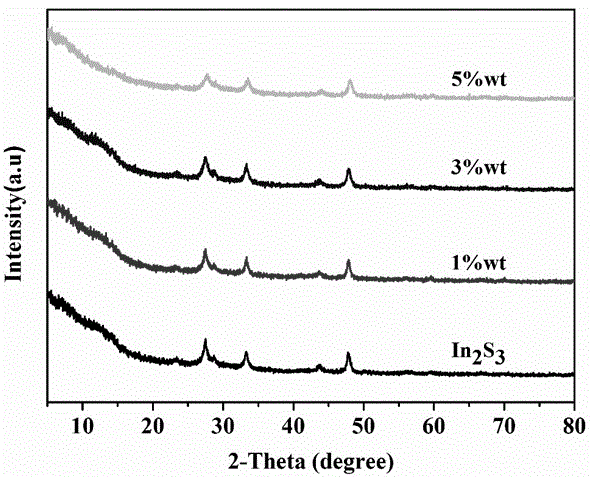

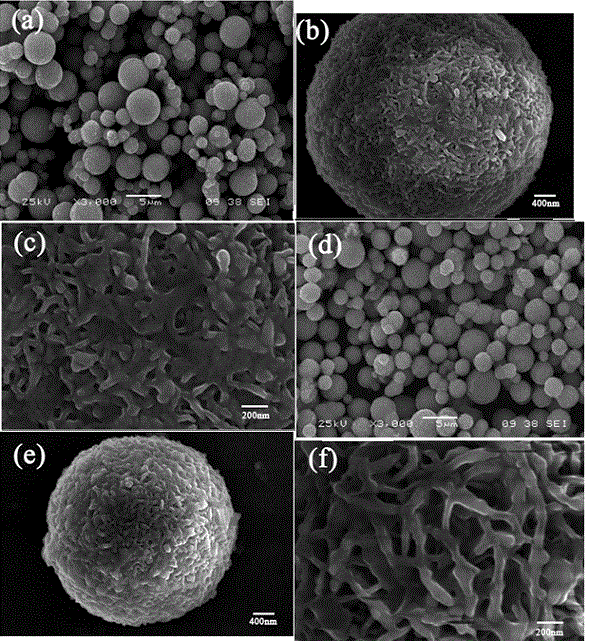

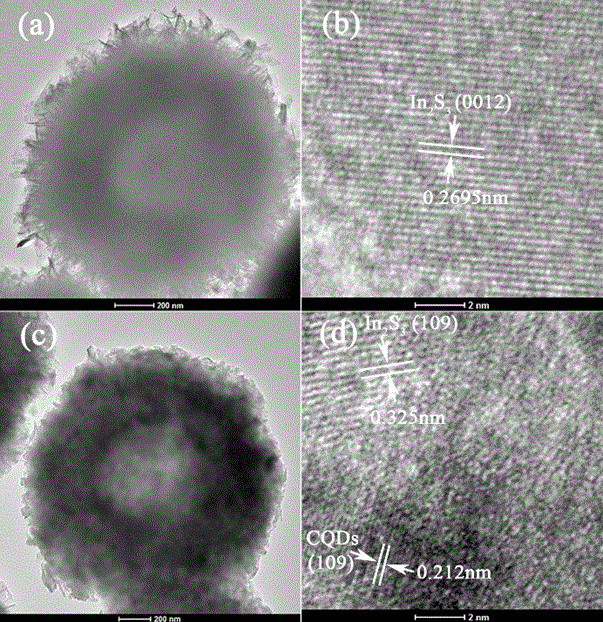

[0046] Example 21wt%CQDs / In 2 S 3 preparation of

[0047] 1. Preparation of carbon quantum dots

[0048] 1. Dissolve 1.0507g of citric acid and 335μL of ethylenediamine in 10ml of distilled water, and stir for 5 minutes to obtain solution A.

[0049] 2. Transfer the upper solution A to a 30ml reaction kettle lined with polytetrafluoroethylene, put it into an oven, and react at a temperature of 180°C for 5 hours.

[0050] 3. After naturally cooling to room temperature, dialyze to obtain solution B containing carbon quantum dots.

[0051] 4. Solution B was centrifuged at 14000r / min for 10 minutes to obtain solution C.

[0052] 5. Solution C was freeze-dried for 24 hours to obtain carbon quantum dot powder.

[0053] 2. Preparation of carbon quantum dots modified mesoporous hollow microspheres indium sulfide

[0054] 1.1 mmol of indium chloride and 1.5 mmol of L-cysteine were dissolved in 25 ml of distilled water and stirred for 5 minutes to obtain solution D.

[0055] 2....

Embodiment 33

[0058] Example 33wt%CQDs / In 2 S 3 preparation of

[0059] 1. Preparation of carbon quantum dots

[0060] 1. Dissolve 1.0507g of citric acid and 335μL of ethylenediamine in 10ml of distilled water, and stir for 5 minutes to obtain solution A.

[0061] 2 Transfer the upper solution A to a 30ml reaction kettle lined with polytetrafluoroethylene, put it into an oven, and react at a temperature of 180°C for 5 hours.

[0062] 3. After naturally cooling to room temperature, dialyze to obtain solution B containing carbon quantum dots.

[0063] 4. Solution B was centrifuged at 14000r / min for 10 minutes to obtain solution C.

[0064] 5. Solution C was freeze-dried for 24 hours to obtain carbon quantum dot powder.

[0065] 2. Preparation of carbon quantum dots modified mesoporous hollow microspheres indium sulfide

[0066] 1.1 mmol of indium chloride and 1.5 mmol of L-cysteine were dissolved in 25 ml of distilled water and stirred for 5 minutes to obtain solution D.

[0067] 2. ...

Embodiment 45

[0070] Example 45wt%CQDs / In 2 S 3 preparation of

[0071] 1. Preparation of carbon quantum dots

[0072] 1. Dissolve 1.0507g of citric acid and 335μL of ethylenediamine in 10ml of distilled water, and stir for 5 minutes to obtain solution A.

[0073] 2 Transfer the upper solution A to a 30ml reaction kettle lined with polytetrafluoroethylene, put it into an oven, and react at a temperature of 180°C for 5 hours.

[0074] 3. After naturally cooling to room temperature, dialyze to obtain solution B containing carbon quantum dots.

[0075] 4. Solution B was centrifuged at 14000r / min for 10 minutes to obtain solution C.

[0076] 5. Solution C was freeze-dried for 24 hours to obtain carbon quantum dot powder.

[0077] 2. Preparation of carbon quantum dots modified mesoporous hollow microspheres indium sulfide

[0078] 1.1 mmol of indium chloride and 1.5 mmol of L-cysteine were dissolved in 25 ml of distilled water and stirred for 5 minutes to obtain solution D.

[0079] 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com