Preparation method of graphite/SiC composite material

A composite material and graphite technology, which is applied in the field of preparation of graphite/SiC composite materials, can solve the problems of destroying the graphite structure and affecting the properties of graphite, and achieves the effects of low preparation cost, excellent mechanical properties, and short preparation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

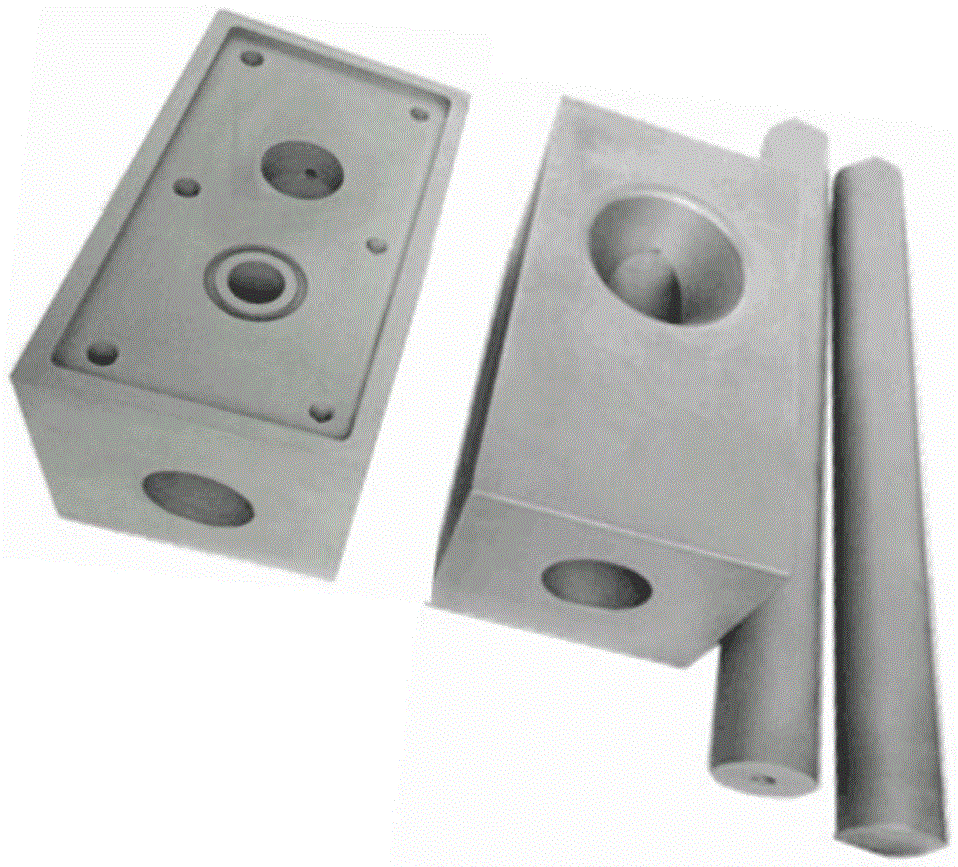

Embodiment 1

[0064] The density is 1.69g / cm 3 Dry and clean isostatic graphite is used as raw material; after processing according to the designed size, the following operations are performed:

[0065] Step 1: Ceramicization of graphite body

[0066] step one a

[0067] Put the graphite blank into the impregnation tank, vacuumize after sealing, control the vacuum degree below 0.001MPa, inhale a certain amount of impregnation liquid, the impregnation liquid is polymethylsilane and styrene according to the mass ratio of 100:20, vacuum Immerse for 2 hours, increase the pressure to 3MPa, and impregnate for 2 hours; discharge the material, take out the graphite body containing the impregnating liquid, place it in a graphite crucible, put it into a vacuum sintering furnace, and solidify at 600°C under a protective atmosphere, keep it warm for 1h, and crack at 1300°C , keep warm for 1h, cool down, take out the workpiece, and perform surface grinding and cleaning;

[0068] step oneb

[0069] A...

Embodiment 2

[0087] The density is 1.78g / cm 3 Dry and clean isostatic graphite is used as raw material; after processing according to the designed size, the following operations are performed:

[0088] Step 1: Ceramicization of graphite body

[0089] step one a

[0090] Put the graphite blank into the impregnation tank, vacuumize after sealing, control the vacuum degree below 0.001MPa, suck a certain amount of impregnation liquid, the impregnation liquid is polymethylsilane and styrene according to the mass ratio of 100:15, vacuum Immerse for 2.5 hours, increase the pressure to 2.7MPa, and impregnate for 2.5 hours; discharge the material, take out the graphite body containing the impregnating liquid, place it in a graphite crucible, put it into a vacuum sintering furnace, and cure it at 500°C under a protective atmosphere, and keep it for 1 hour. Crack at 1250°C, keep warm for 1.5h, cool down, take out the workpiece, polish and clean the surface;

[0091] step oneb

[0092] After repea...

Embodiment 3

[0110] The density is 1.85g / cm 3 Dry and clean isostatic graphite is used as raw material; after processing according to the designed size, the following operations are performed:

[0111] Step 1: Ceramicization of graphite body

[0112] step one a

[0113] Put the graphite blank into the impregnation tank, vacuumize after sealing, control the vacuum degree below 0.001MPa, suck a certain amount of impregnation liquid, the impregnation liquid is polymethylsilane and styrene according to the mass ratio of 100:10, vacuum Immerse for 3 hours, increase the pressure to 3MPa, and impregnate for 3 hours; discharge the material, take out the graphite body containing the impregnating liquid, place it in a graphite crucible, put it into a vacuum sintering furnace, solidify at 450°C under a protective atmosphere, keep it warm for 1h, and crack at 1200°C , keep warm for 2h, cool down, take out the workpiece, and perform surface grinding and cleaning.

[0114] step oneb

[0115] After r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com