Polymerization method for preparing fluorine-containing alternating copolymer through gradual transfer-addition-ending step by step with free radicals under condition of visible light

A technology of alternating copolymers and polymerization methods, applied in the field of controlled sequence polymerization, can solve the problems of low polymer molecular weight, low monomer conversion rate, long polymerization reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

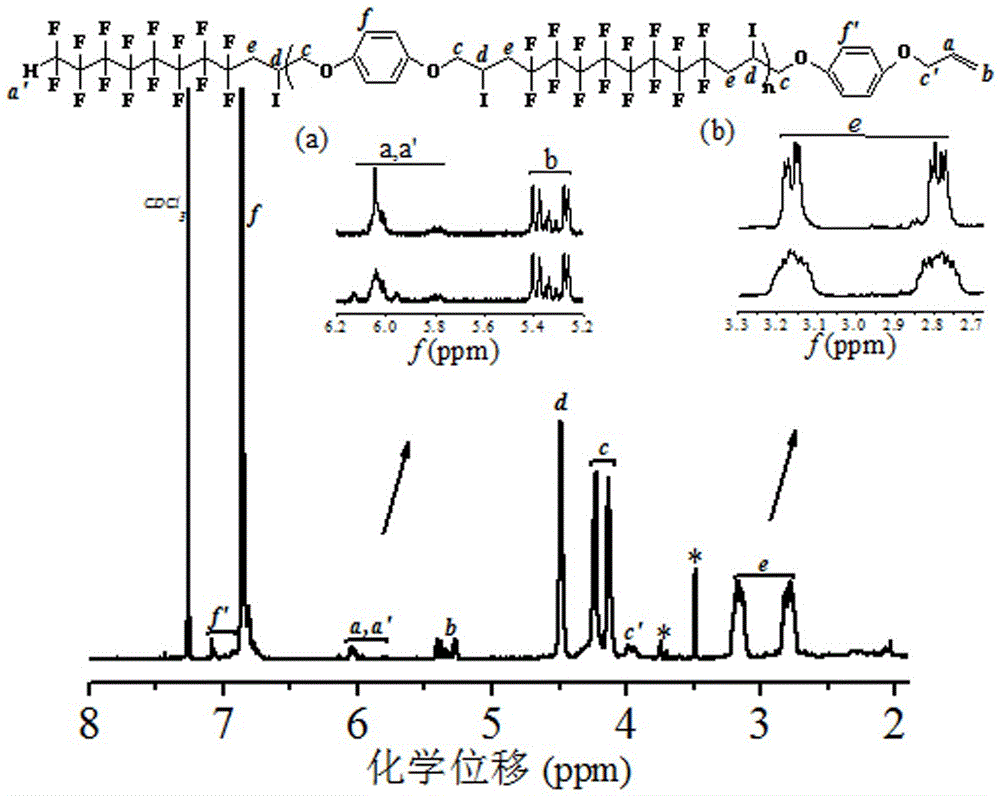

[0028] A polymerization method for preparing fluorine-containing alternating copolymers by using free radicals to gradually transfer-addition-terminate under visible light conditions. The preparation steps of the method are as follows:

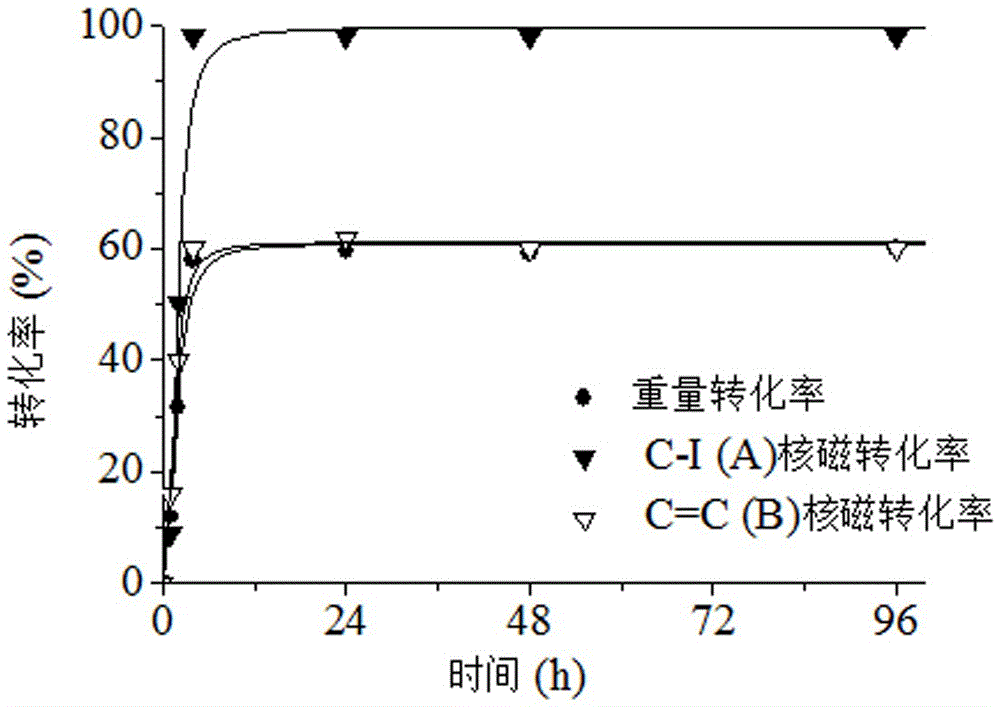

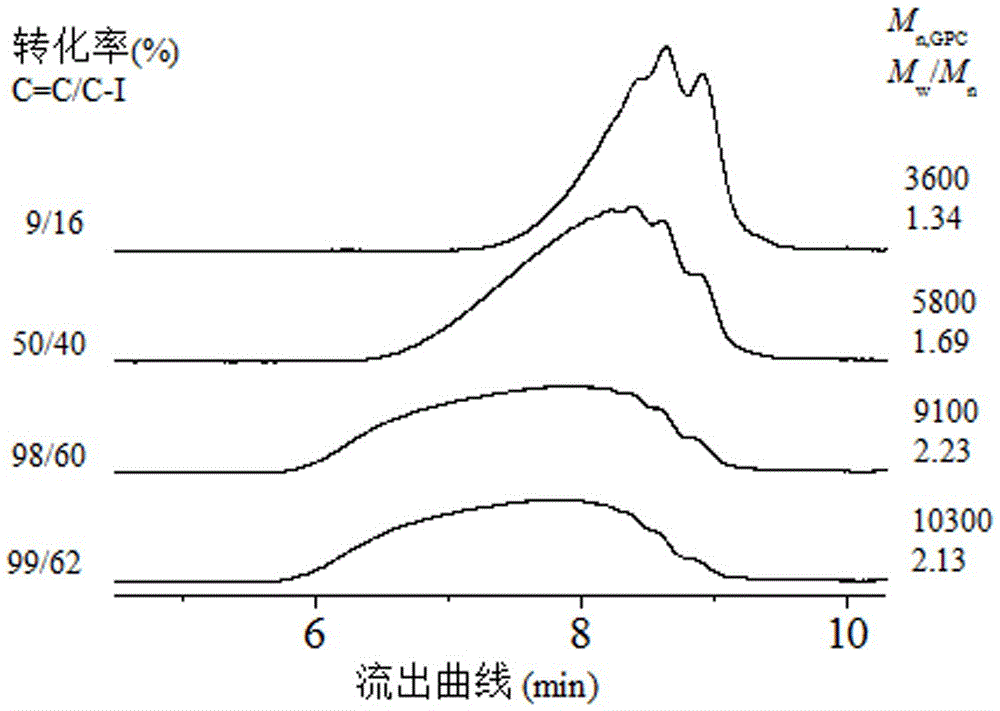

[0029] (1) Mix 0.5mmol of 1,8-diiodoperfluorooctane, 0.5mmol of 1,4-bis(allyloxy)benzene, 0.025mmol of Ru(bpy) 3 Cl 2 , 0.175mmol of sodium ascorbate, and a mixed organic solvent composed of 3mL of acetonitrile and 1mL of methanol are all added to the reaction vessel, and a stirrer is added to the reactor, stirred to make the system homogeneous, and sealed after four deoxygenation operations Reaction vessel, obtains homogeneous polymerization system I;

[0030] (2) Set the temperature of the reaction vessel at 25°C and the rotation speed at 1800rpm, and conduct the polymerization reaction of the homogeneous polymerization system I under LED blue light illumination, and the reaction time is 24h;

[0031] (3) After the reaction, open the react...

Embodiment 2

[0033] A polymerization method for preparing fluorine-containing alternating copolymers by using free radicals to gradually transfer-addition-terminate under visible light conditions. The preparation steps of the method are as follows:

[0034] (1) Mix 0.5mmol of 1,8-diiodoperfluorooctane, 0.5mmol of 1,4-bis(enylbutyl)benzene, and 0.025mmol of Ru(bpy) 3 Cl 2 , 0.175mmol of sodium ascorbate, and a mixed organic solvent composed of 3mL of 1,4-dioxane and 1mL of methanol were all added to the reaction vessel, and a stirring bar was added to the reactor, and the system was stirred to make the system homogeneous. After the second deoxygenation operation, the reaction vessel is sealed to obtain the homogeneous polymerization system I;

[0035] (2) Set the temperature of the reaction vessel at 25°C and the rotation speed at 1800rpm, and conduct the polymerization reaction of the homogeneous polymerization system I under LED blue light illumination, and the reaction time is 24h;

[...

Embodiment 3

[0038] A polymerization method for preparing fluorine-containing alternating copolymers by using free radicals to gradually transfer-addition-terminate under visible light conditions. The preparation steps of the method are as follows:

[0039] (1) Mix 0.5mmol of 1,8-diiodoperfluorooctane, 0.5mmol of 1,7-octadiene, and 0.025mmol of Ru(bpy) 3 Cl 2 , 0.175mmol of sodium ascorbate, and a mixed organic solvent composed of 3mL of 1,4-dioxane and 1mL of methanol were all added to the reaction vessel, and a stirring bar was added to the reactor, and the system was stirred to make the system homogeneous. After the second deoxygenation operation, the reaction vessel is sealed to obtain the homogeneous polymerization system I;

[0040] (2) Set the temperature of the reaction vessel at 25°C and the rotation speed at 1800rpm, and conduct the polymerization reaction of the homogeneous polymerization system I under LED blue light illumination, and the reaction time is 24h;

[0041] (3) Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com