Method for preparing dissolving pulp by using cotton linters

A technology of cotton linter and dissolving pulp, which is applied in the direction of pulping with inorganic alkali, pulping of cellulose raw materials, pulp bleaching, etc., can solve the problems of large pollution, large amount of drugs, harsh reaction conditions, etc. The effect of reducing the amount of alkali used and reducing the degree of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

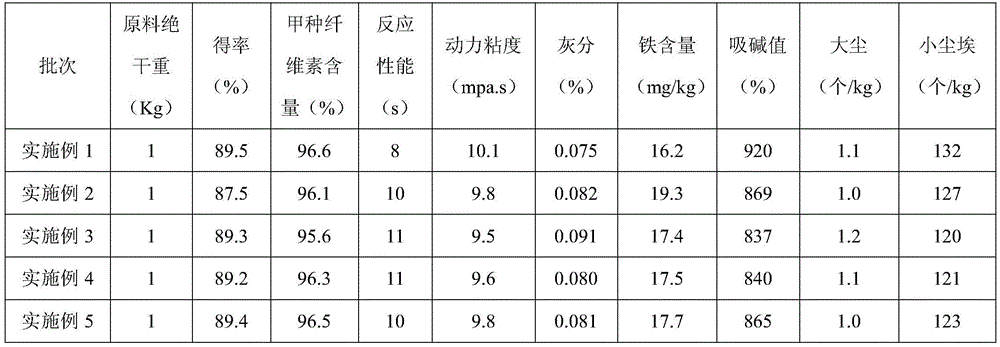

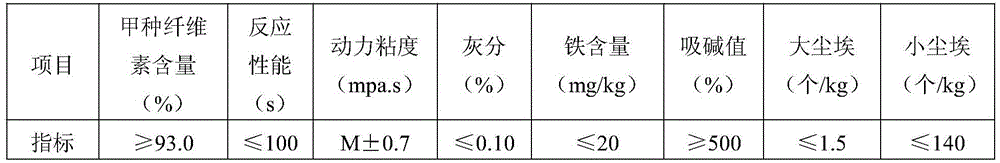

Examples

Embodiment 1

[0019] A method for preparing dissolving pulp from cotton linters, comprising enzyme treatment, steam bleaching treatment and acid treatment, wherein sulfuric acid is firstly used for acid pretreatment before enzyme treatment.

[0020] The specific steps are:

[0021] Step 1: Acid Pretreatment

[0022] Add 1Kg (absolute dry weight) of cotton linters for raw materials in the stainless steel stirred tank, add sulfuric acid with a pH of 1.5, adjust the slurry concentration to 9%, and process at 30° C. for 12 hours.

[0023] Step 2: Enzyme Treatment

[0024] Wash the slurry after the acid treatment, after washing, add dipotassium hydrogen phosphate-potassium dihydrogen phosphate buffered saline solution to the system, adjust the pH of the system to 7.5, and the slurry concentration is 5%, add 150000U ferulic acid esterase, The ratio of lipase, ferulic acid esterase and lipase enzyme dosage is 8:3, and treated at 70° C. for 2 hours.

[0025] The third step: chemical steam bleach...

Embodiment 2

[0034] A method for preparing dissolving pulp from cotton linters, comprising enzyme treatment, steam bleaching treatment and acid treatment, wherein sulfuric acid is firstly used for acid pretreatment before enzyme treatment.

[0035] The specific steps are:

[0036] Step 1: Acid Pretreatment

[0037] Add 1Kg (absolute dry weight) of cotton linters for the preparation in the stainless steel stirred tank, add the sulfuric acid that pH is 4, adjust the slurry concentration to be 10%, and process at 90° C. for 2 hours.

[0038] Step 2: Enzyme Treatment

[0039] Wash the slurry after acid treatment. After washing, add dipotassium hydrogen phosphate-potassium dihydrogen phosphate buffered saline solution to the system to adjust the pH of the system to 6.5, and the slurry concentration is 6%. Add 15000U lipase and cellulase , the enzyme dosage ratio of lipase and cellulase was 4:15, and treated at 45°C for 35h.

[0040] The third step: chemical steam bleaching treatment

[0041...

Embodiment 3

[0049] A method for preparing dissolving pulp from cotton linters, comprising enzyme treatment, steam bleaching treatment and acid treatment, wherein sulfuric acid is firstly used for acid pretreatment before enzyme treatment.

[0050] The specific steps are:

[0051] Step 1: Acid Pretreatment

[0052] Add 1Kg (absolute dry weight) of cotton linters for raw materials into the stainless steel stirred tank, add sulfuric acid with a pH of 5, adjust the slurry concentration to 9%, and process at 70°C for 7 hours.

[0053] Step 2: Enzyme Treatment

[0054] Wash the slurry after the acid treatment. After washing, add dipotassium hydrogen phosphate-potassium dihydrogen phosphate buffered saline solution to adjust the pH of the system to 8, and the slurry concentration is 7%. Add 100000U ferulic acid esterase and The ratio of cellulase, ferulic acid esterase and cellulase is 9:23, and treated at 65°C for 10 hours.

[0055] The third step: chemical steam bleaching treatment

[0056...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com