A liquid crystal coating device and method

A liquid crystal coating, liquid crystal technology, applied in the device, coating, optics and other directions of coating liquid on the surface, can solve the problems of fast liquid crystal diffusion, pollution, lowering temperature, etc., to improve the anti-pollution ability and solve the pollution problem , does not affect the effect of the beat time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

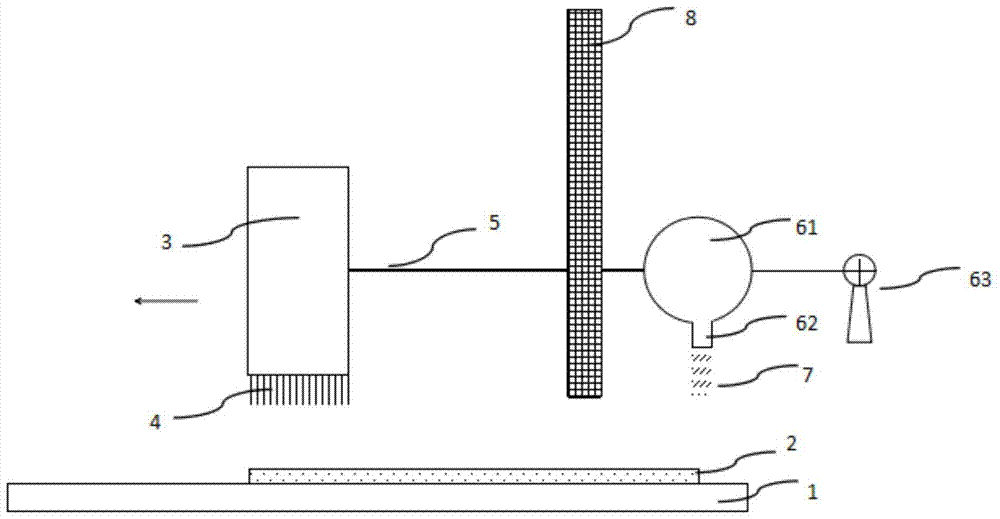

[0032] Such as figure 1 As shown, a liquid crystal coating device described in this embodiment includes a liquid crystal shower head 3 for coating liquid crystal 2 and a gas cooling device 6 for cooling the coated liquid crystal 2, and the gas cooling device 6 Located behind the liquid crystal shower head 3 and moving along the trajectory of the liquid crystal shower head 3, the liquid crystal shower head 3 ejects liquid crystal through its nozzle 4, and the gas cooling device 6 cools the liquid crystal 2 rapidly.

[0033] The gas cooling device 6 includes an air circuit system 63 and an air injection chamber 61. The air injection chamber 61 communicates with the gas storage device 9 through the air circuit system 63. The gas circuit system 63 is provided with a flow valve for controlling the flow of gas. The flow valve and the flow valve can adjust the size of the gas flow and the temperature of the low-temperature gas, so that the low-temperature gas can be gently applied to...

Embodiment 2

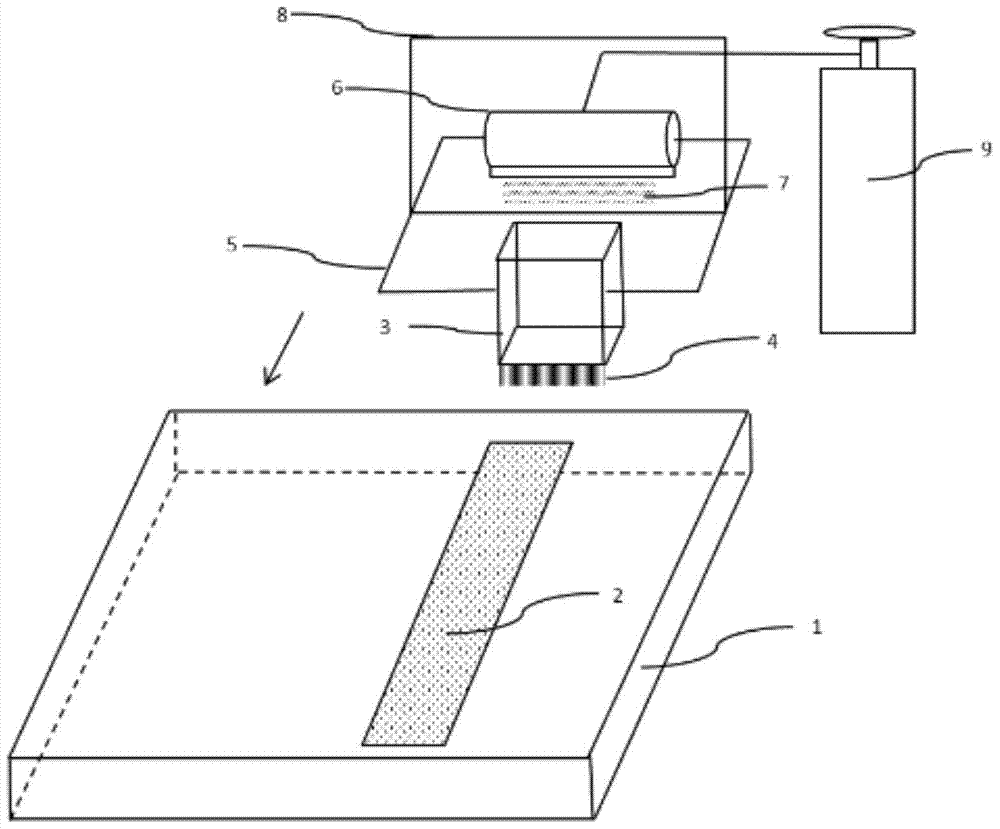

[0039] The liquid crystal coating method described in this embodiment adopts the liquid crystal coating device described in Embodiment 1, and the schematic diagram of the liquid crystal coating device in use is as follows figure 2 shown.

[0040] A kind of liquid crystal coating method described in the present embodiment comprises the following steps:

[0041] S1, through the liquid crystal nozzle 3 figure 2 Spray evenly a set pattern and quantity of liquid crystals 2 on the substrate 1 in the direction shown in ;

[0042] S2. While spraying the liquid crystal 2, the gas cooling device 6 gently sprays high-purity low-temperature dry gas 7 to cool down the liquid crystal 2 on the substrate 1 along the trajectory of the liquid crystal 2 coating, reducing the fluidity of the liquid crystal 2 and increasing the viscosity. Hysteresis coefficient, reducing the diffusion speed of liquid crystal 2;

[0043] S3. Carrying out thermal curing treatment on the frame sealing glue, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com