Germinated brown rice preparation method

A technology for germinated brown rice and brown rice, which is applied in the field of automatic control of germinated brown rice production equipment and brown rice preparation, can solve the problems of inconvenient operation, bactericide residue, and easy error, and achieve the effects of simple operation, pollution avoidance, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

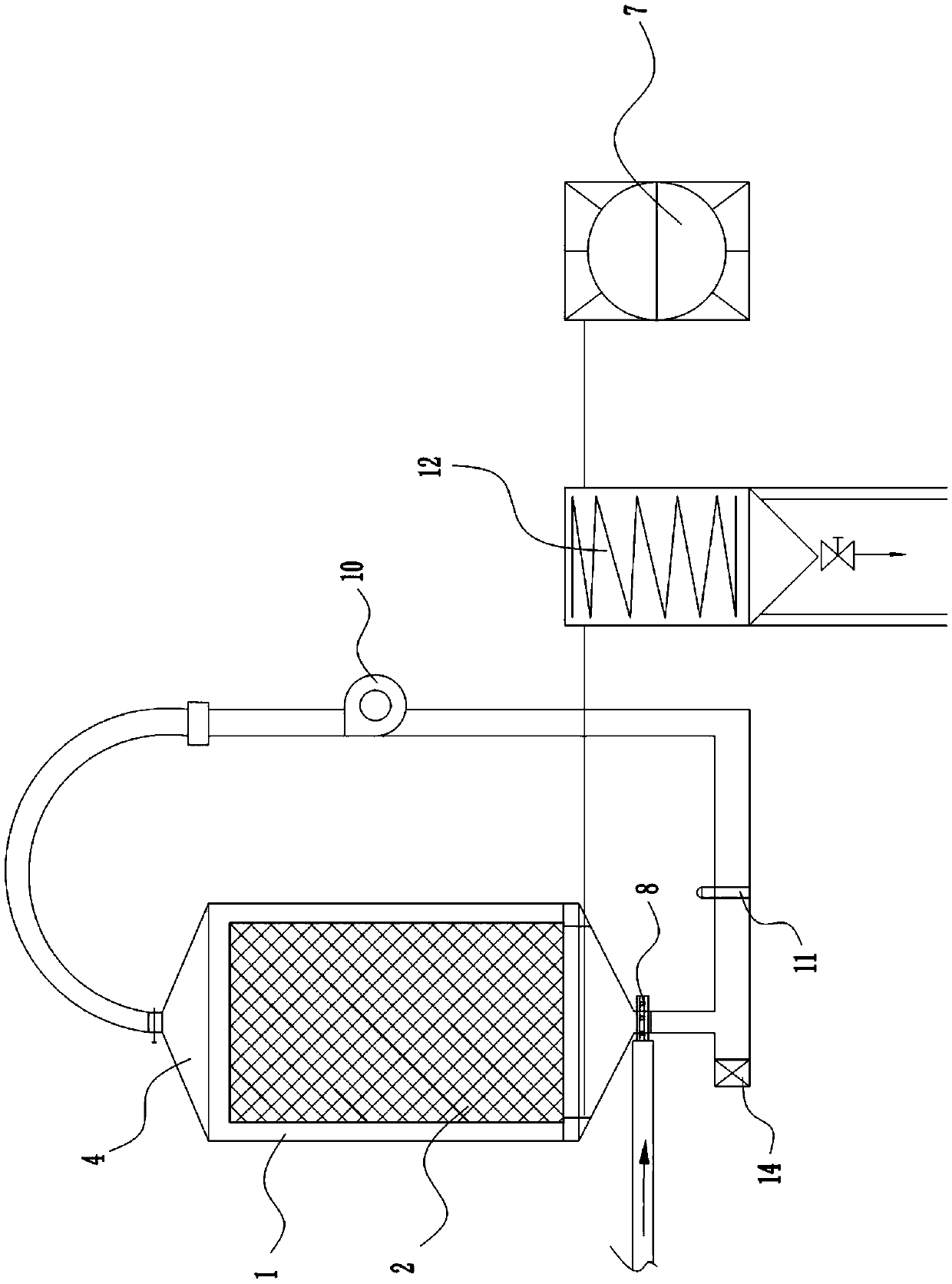

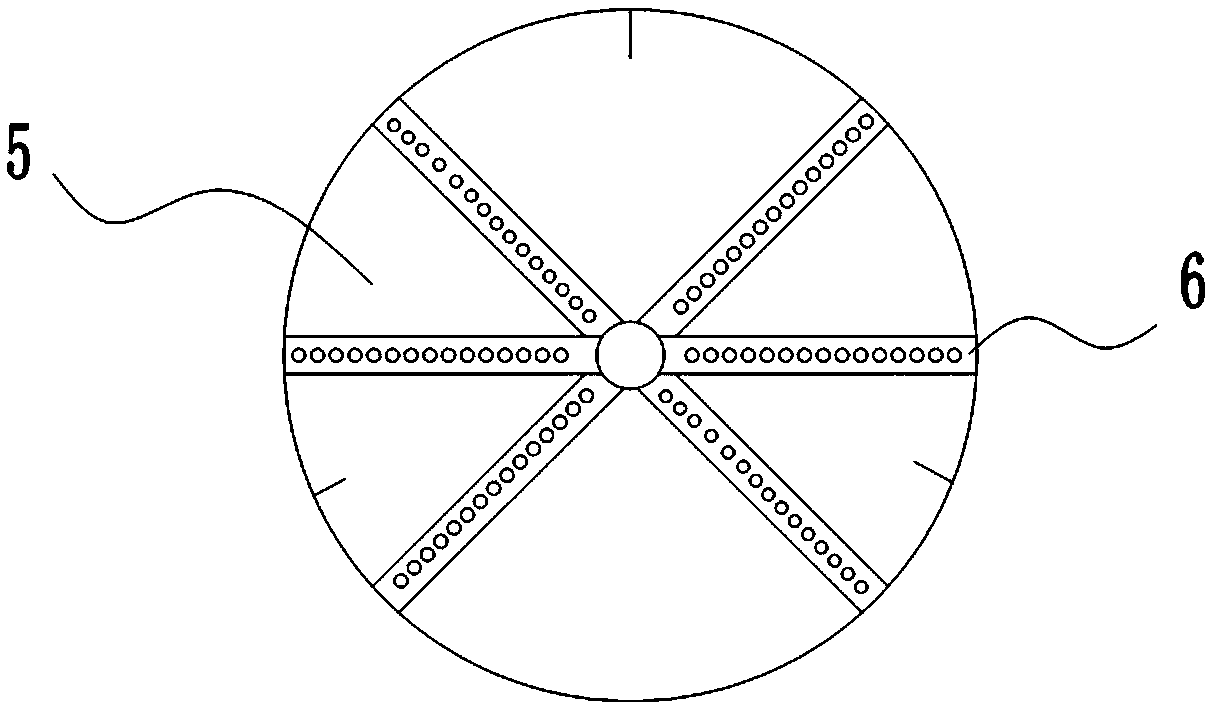

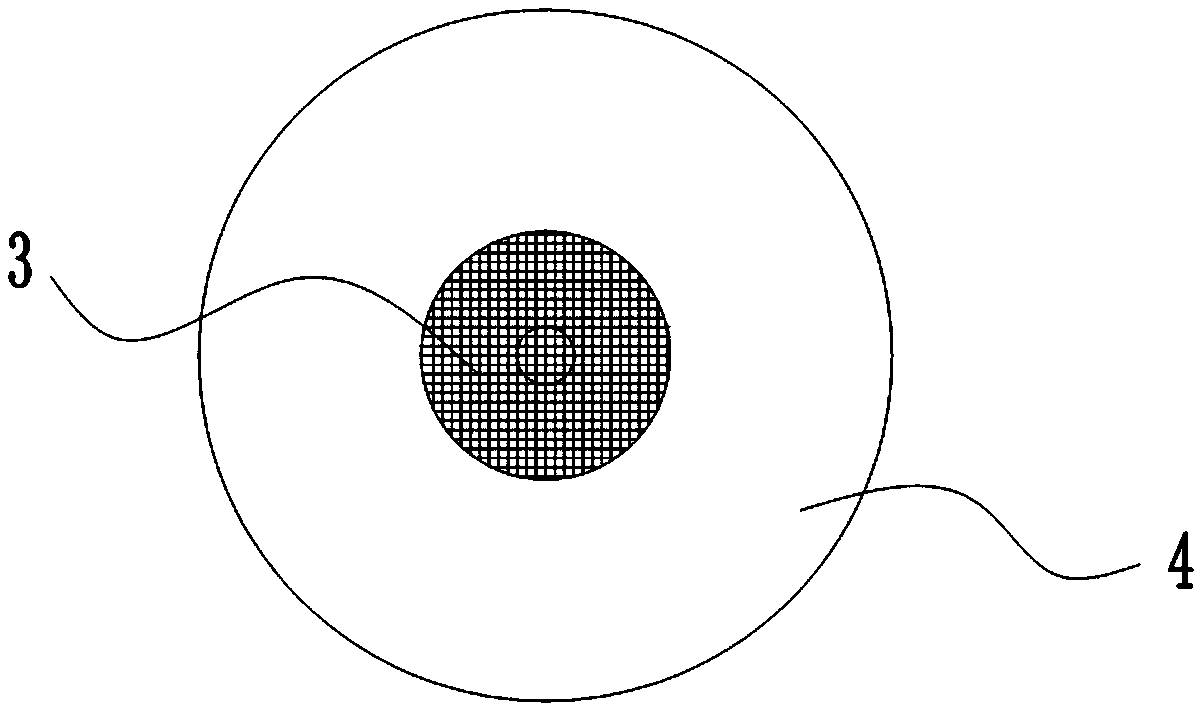

[0036] Such as Figure 1-3 As shown, the automatic control production device for germinated brown rice includes an outer container 1 with a funnel-shaped bottom and an inner container 2 that is made of stainless steel mesh contained in the outer container 1; The outer container cover 4, the funnel-shaped upper part of the outer container is provided with a support 5 for supporting the inner container, the support 5 is provided with an electric heater and a plurality of connected ventilation pipes 6 distributed in the shape of a rice, and the ventilation pipe There are air holes evenly distributed towards the inner container, and the ventilation pipe is connected with the air pump 7 through the pipeline; the funnel-shaped bottom of the outer container is provided with a water inlet, and the water inlet is connected with the water inlet device through the three-way valve 8, and the other way is through the circulating water pipeline Connected to sprinkler head.

[0037] Such as...

Embodiment 2

[0042] A kind of method utilizing above-mentioned device to prepare germinated brown rice, carries out as follows:

[0043] 1) Soak

[0044] Put the brown rice to be germinated in the inner container, and then fill the outer container with water from the water inlet at the bottom of the outer container, so that the brown rice is completely immersed in the water, and preset the soaking temperature, ventilation frequency, ventilation time, and soaking time. Turn on the control switch and soak the brown rice in water at 25-30°C for 8-12 hours. The volume is 60L / min per 50-100Kg of brown rice, and the sound and light will prompt when the soaking is over, and the soaked water will be drained;

[0045] 2) Sterilization

[0046] Re-inject clean water into the outer container to submerge the brown rice into the water, turn on the ozone generator and air pump at the same time, the ozone generation rate is 5L / min, and the ozone treatment is for 10 minutes; let it stand for 5-10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com