Microporous sponge slow-releasing pesticide block and preparation method thereof

A microporous sponge and slow-release pesticide technology, applied in the field of pesticides, can solve the problems of unstable release of pesticide active ingredients, complex preparation process, low preparation content, etc., to achieve the effect of improving biodegradability and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

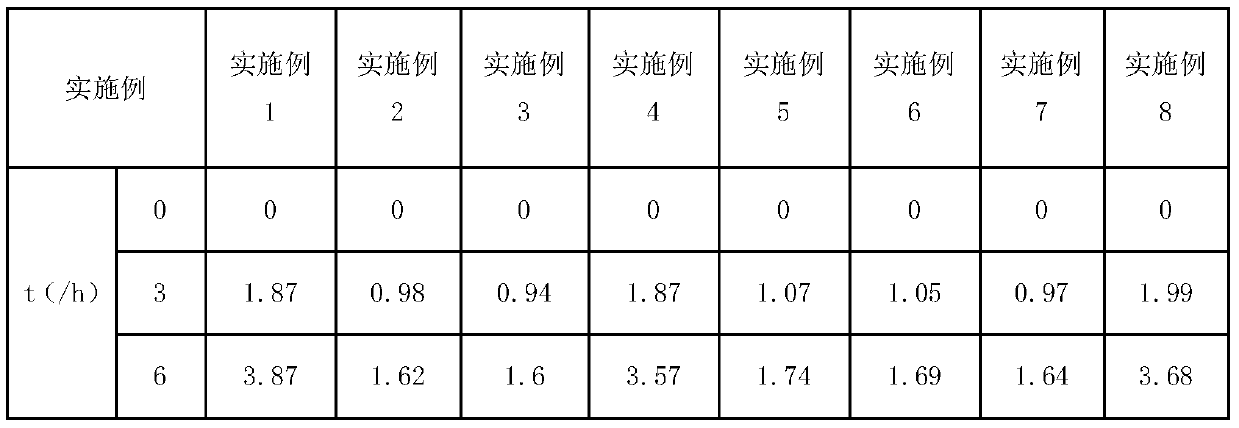

Examples

preparation example Construction

[0029] The preparation method of embodiment 1~5 and comparative example 1~5 is as follows:

[0030] 1) After mixing polyols, biomaterials, pesticide active ingredients, thickeners, emulsifiers, and dispersants, cut them with a high-speed shear for 5-20 minutes, add them to a sand mill, and grind them to a particle size of D 90 ≤10μm, obtain polyol preparatory solution A;

[0031] 2) After adding silicon surfactant, hardener, catalyst and foaming agent to the polyol preparatory solution A, stir vigorously for 8 seconds to 10 minutes to obtain the polyol preparatory solution B;

[0032] 3) Add the polyisocyanate to the polyol preparatory solution B, stir evenly, and let stand to foam for 1min to 24h;

[0033] 4) After the mixed solution no longer foams, cut the obtained microporous spongy foam containing pesticide active ingredients into a regular shape to obtain a microporous spongy slow-release pesticide block.

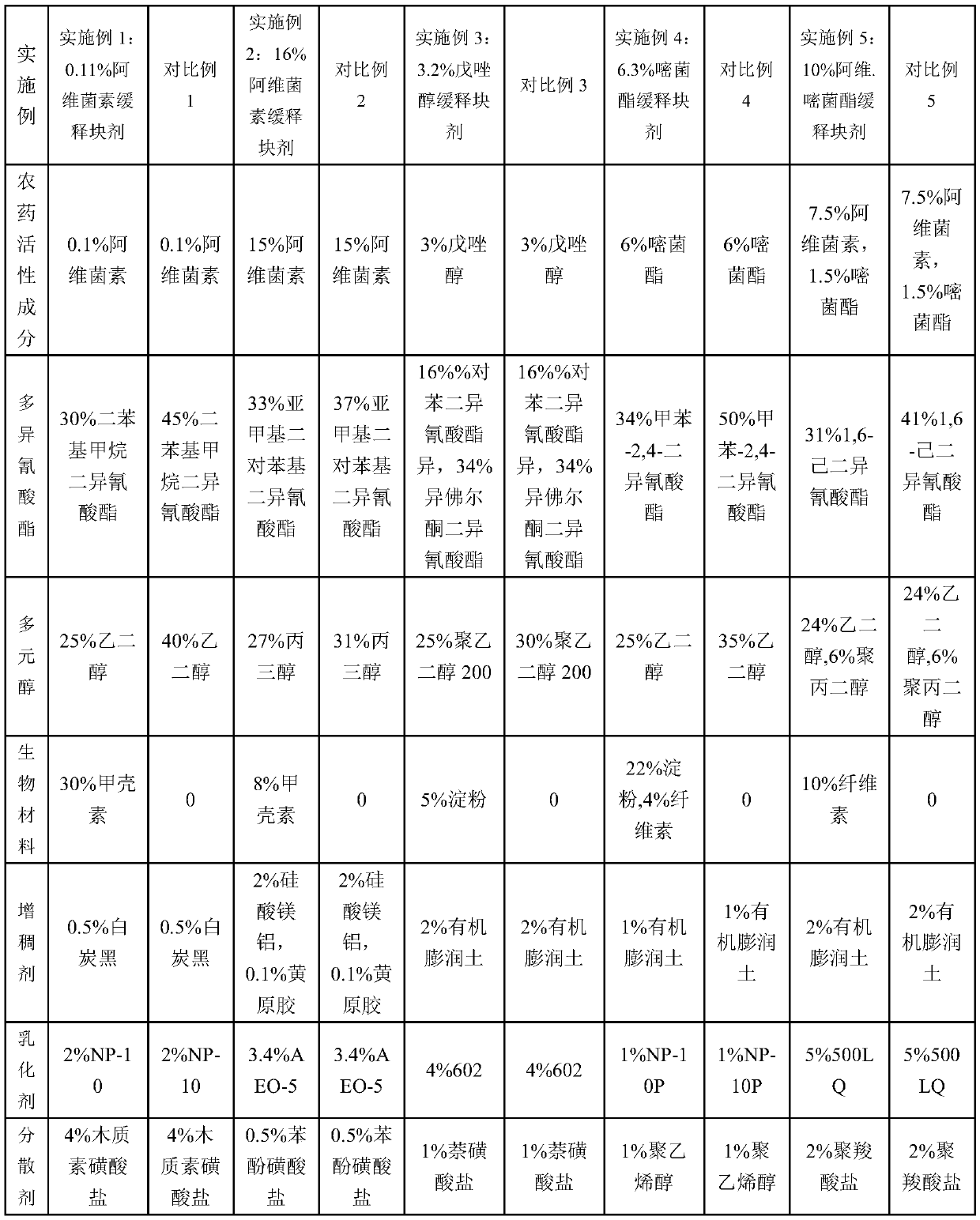

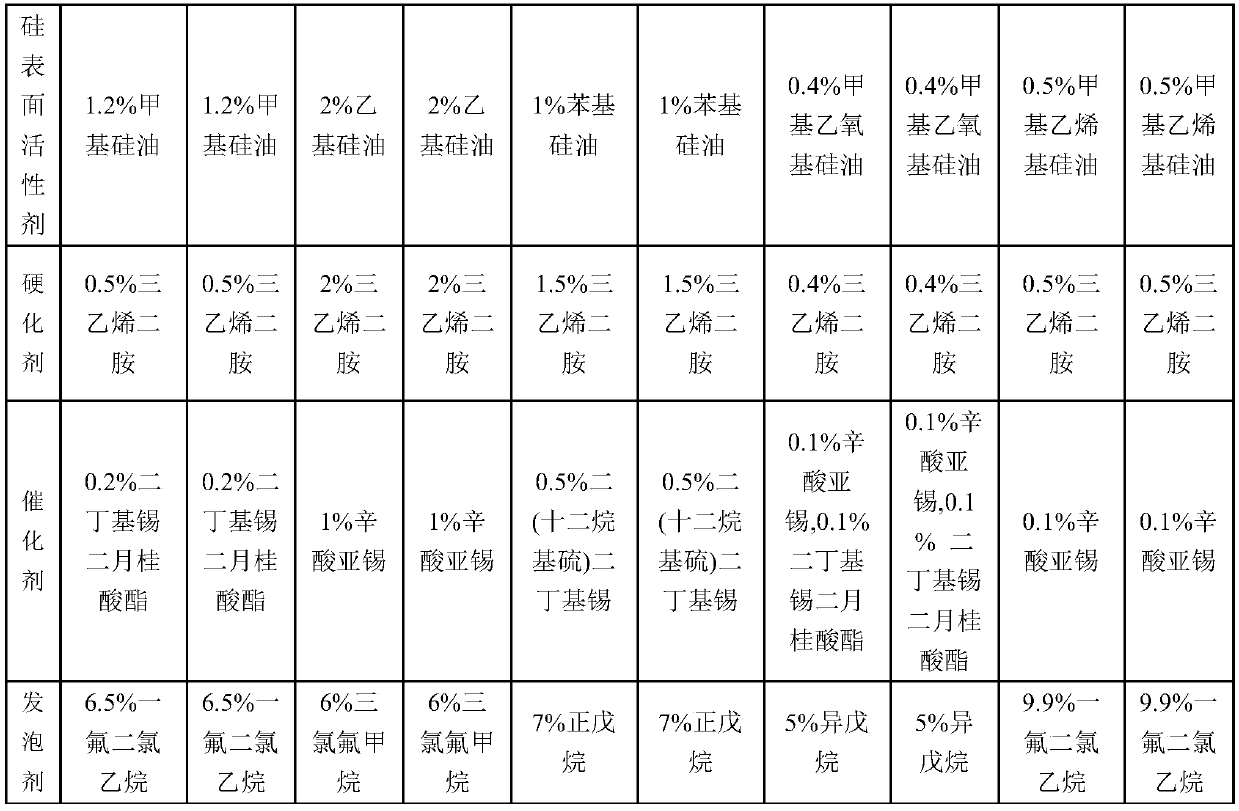

[0034] Table 1 embodiment 1~5 and each component weight percen...

Embodiment 60

[0039] Embodiment 60.5% abamectin microcapsule suspension

[0040] Each component weight percentage of formula forms:

[0041] 16% Abamectin slow-release block prepared by 3.2% embodiment 2, 0.5% polycarboxylate, 3% arylphenol polyoxyethylene polyoxypropylene ether phosphate triethanol ammonium salt, 1% isooctyl succinate Sodium Acid, 3% Glycol, 1% Magnesium Aluminum Silicate, 0.12% Xanthan Gum, Water Make Up 100%.

[0042] Preparation:

[0043] 1) The 16% Abamectin sustained-release block prepared in Example 2 is pulverized to 100-150 mesh by air flow;

[0044] 2) Take by weighing 3.2g16% Abamectin sustained-release block powder, 0.5g polycarboxylate, 3g arylphenol polyoxyethylene polyoxypropylene ether phosphate triethanol ammonium salt, 1g isooctyl sodium succinate, 3g of ethylene glycol, 1g of magnesium aluminum silicate, 0.12g of xanthan gum, 100% of water, high-speed shearing for 3min, and wet sanding to 150-200 mesh to obtain 0.5% abamectin microcapsule suspension. ...

Embodiment 71

[0050] Example 7 1.5% tebuconazole sustained-release powder

[0051] Each component weight percentage of formula forms:

[0052] 46.9% of the 3.2% tebuconazole slow-release block prepared in Example 3, 12% white carbon black, 15% lignosulfonate, and kaolin make up 100%.

[0053] Preparation:

[0054] 1) The 3.2% tebuconazole sustained-release block prepared in Example 3 was pulverized by air flow to 100-150 mesh;

[0055] 2) Weigh 46.9g of 3.2% tebuconazole slow-release block powder, 12g of white carbon black, 15g of lignin sulfonate, and the remainder of kaolin, mix well, and air-jet mill to obtain 1.5% tebuconazole slow-release powder .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com