Delivery-controllable and release-controllable nanocapsule gel breaker as well as preparation method and application thereof

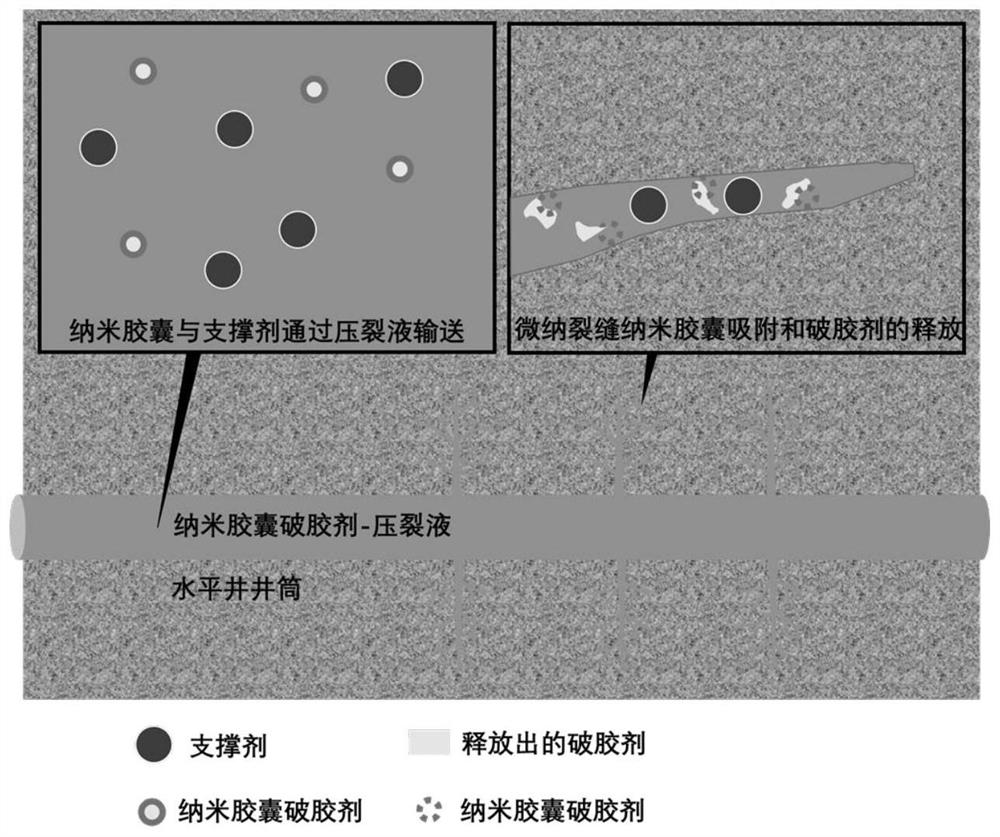

A technology of nanocapsules and gel breakers, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of capsule slow-release time not being too long, reducing raw material usage, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A method for preparing a delivery and release controllable nanocapsule breaker, comprising the steps of:

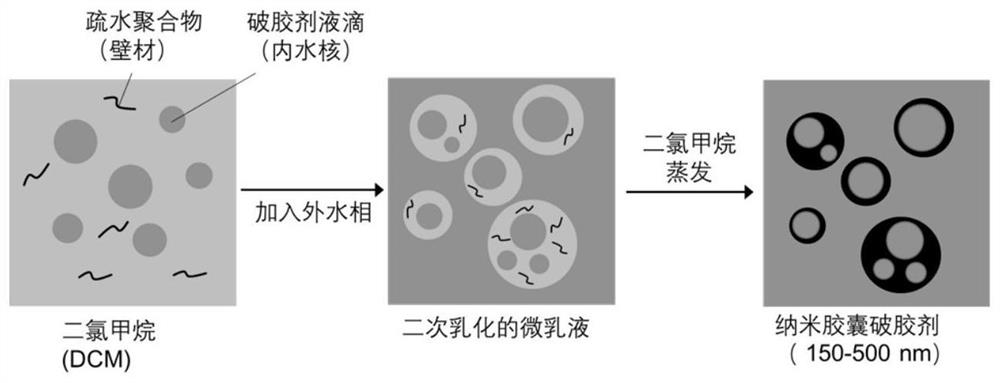

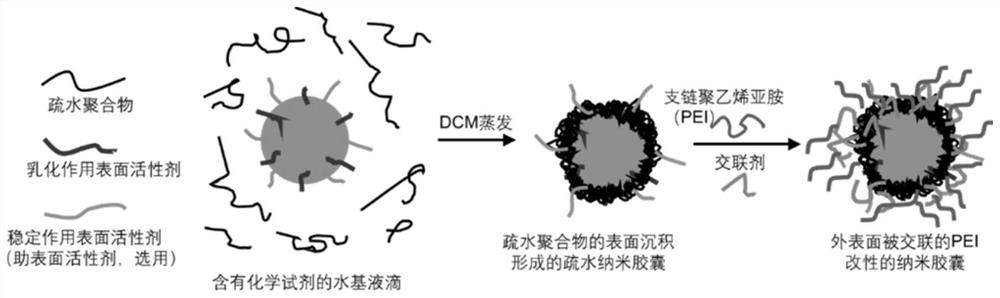

[0070] (1) Preparation of nanocapsule gel breaker by emulsion evaporation

[0071] 1) Add 0.1g of ammonium persulfate to 0.5ml of water to prepare an aqueous solution of ammonium persulfate (inner water core), and dissolve 1.1g of polyglycolide in 10ml of dichloromethane to obtain a hydrophobic polymer oil phase ;

[0072] 2) Add 0.5ml of gel breaker aqueous phase solution into 5ml of hydrophobic polymer oil phase, add 0.05ml of Brij72, and emulsify with a high-speed stirring paddle at a stirring speed of 12000rpm for 5min to obtain an intermediate emulsion;

[0073] 3) Add the intermediate emulsion to 10ml 1wt% polyvinyl alcohol (PVA) solution, carry out secondary emulsification, form a microemulsion, stir (350rpm) at 55°C for 8 hours, separate the nanocapsule breaker from the oil phase, and wash , dried, and then secondarily dispersed in water to obtain a 2wt.%...

Embodiment 2

[0079] A method for preparing a delivery and release controllable nanocapsule breaker, comprising the steps of:

[0080] (1) Preparation of nanocapsule gel breaker by emulsion evaporation

[0081] 1) Add 0.1g of ammonium persulfate to 0.5ml of water to obtain an aqueous solution of ammonium persulfate (inner water core), and dissolve 0.9g of polycaprolactone in 10ml of dichloromethane to obtain a hydrophobic polymer oil phase ;

[0082] 2) Add 0.5ml of gel breaker aqueous phase solution into 5ml of hydrophobic polymer oil phase, add Tergitol NP-40.05ml and Brij L-4 0.05ml, use high-speed stirring paddle for emulsification, stirring speed 12000rpm, stirring time 5min, get intermediate emulsion;

[0083] 3) Add the intermediate emulsion to 10ml 1wt% polyvinyl alcohol (PVA) solution, perform secondary emulsification to form a microemulsion, stir (350rpm) at 50°C for 8 hours, separate the nanocapsule breaker from the oil phase, and wash , dried, and then secondarily dispersed i...

Embodiment 3

[0087] A method for preparing a delivery and release controllable nanocapsule breaker, comprising the steps of:

[0088] (1) Preparation of nanocapsule gel breaker by emulsion evaporation

[0089] 1) Add 0.3g of pectinase to 0.6ml of water to prepare a pectinase aqueous phase solution (inner water core), add 0.6g of polymethyl methacrylate (PMMA) to dissolve in 10ml of dichloromethane to obtain a hydrophobic polymer oil phase;

[0090] 2) Add 0.5ml of gel breaker aqueous phase solution into 5ml of hydrophobic polymer oil phase, add 0.1ml of Brij72, and emulsify with a high-speed stirring paddle (12000rpm, 5min) to obtain an intermediate emulsion;

[0091] 3) Add the intermediate emulsion into 20ml of hexane solution for secondary emulsification to form a microemulsion, stir (300rpm) at 50°C for 8 hours to evaporate, separate the nanocapsule breaker from the oil phase, wash, dry, and then dissolve in water Secondary dispersion to obtain 2wt.% nanocapsule dispersion;

[0092]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com