Cu/ZnO catalyst, preparation method thereof and application thereof to CO2 chemical conversion

A catalyst and reaction technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as no patent reports in the field of chemical transformation, and achieve reactivity and high stability, low reaction temperature, and the effect of suppressing the decrease in specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

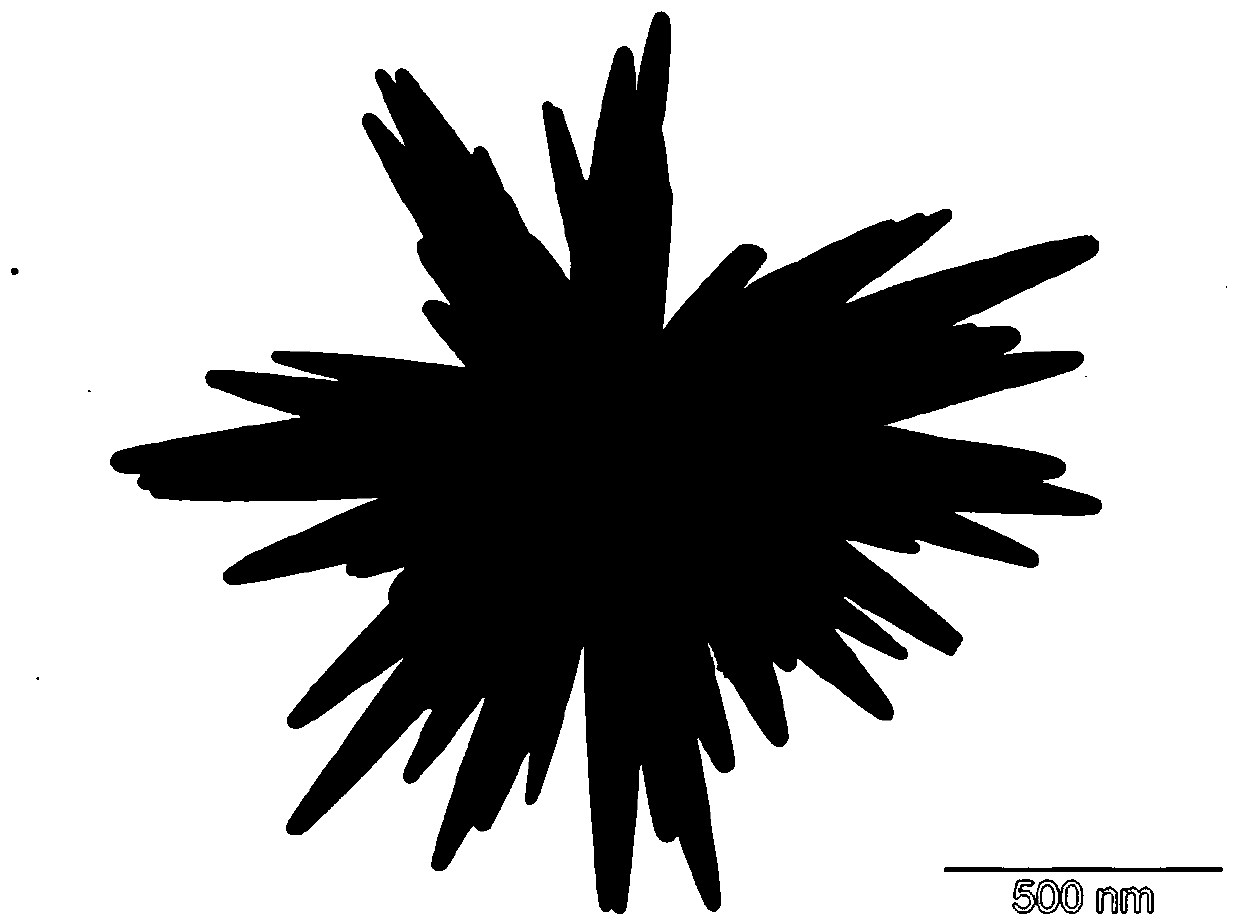

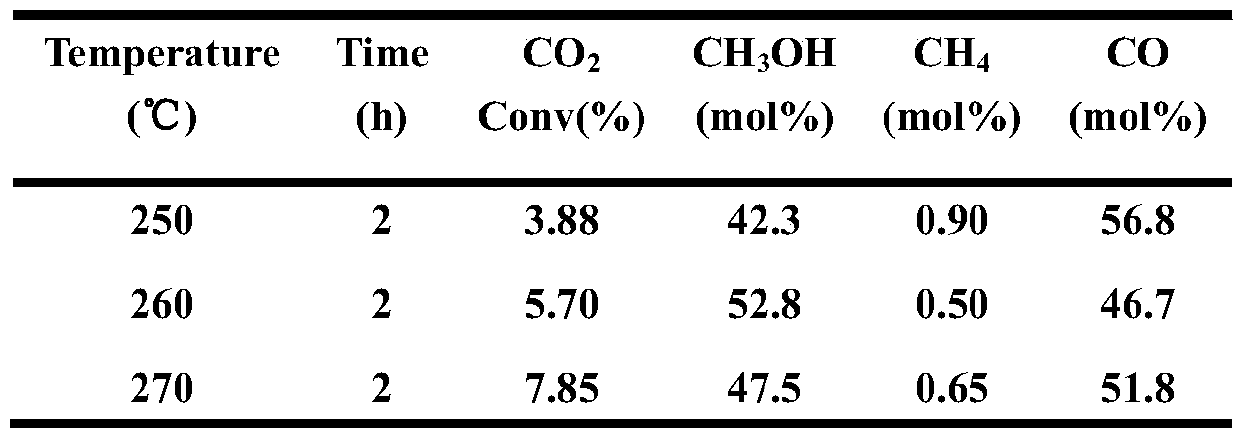

[0024] (1) 5g Zn(NO 3 ) 2 .6H 2 O and hexamethylenetetramine were dissolved in 100 mL of 15 wt % aqueous ethylene glycol. Under a nitrogen atmosphere, the reaction was carried out in a microwave reactor with a power of 300W for 10 minutes. Cool down to room temperature, filter the precipitate with suction, wash with hot deionized water until neutral, and dry at 90°C for 12 hours. Synthesis of ZnO-1 carrier. Such as figure 1 As shown, the ZnO carrier in the obtained catalyst has a uniform nano-flower shape; the petals are rod-shaped, and the length of the petals is 300-600 nm; the diameter is 20-40 nm.

[0025] (2) 2.84gCu(NO 3 ) 2 , 5.1 g of the ZnO carrier obtained in (1) was added to 150 mL of deionized water. Stir magnetically at 600r / min and heat to 75°C, slowly add 0.1mol / L Na 2 CO 3 The solution was further stirred and aged for 2 hours until the pH was 9-10, the precipitate was suction filtered, washed with hot deionized water until neutral, dried at 90°C for 1...

Embodiment 2

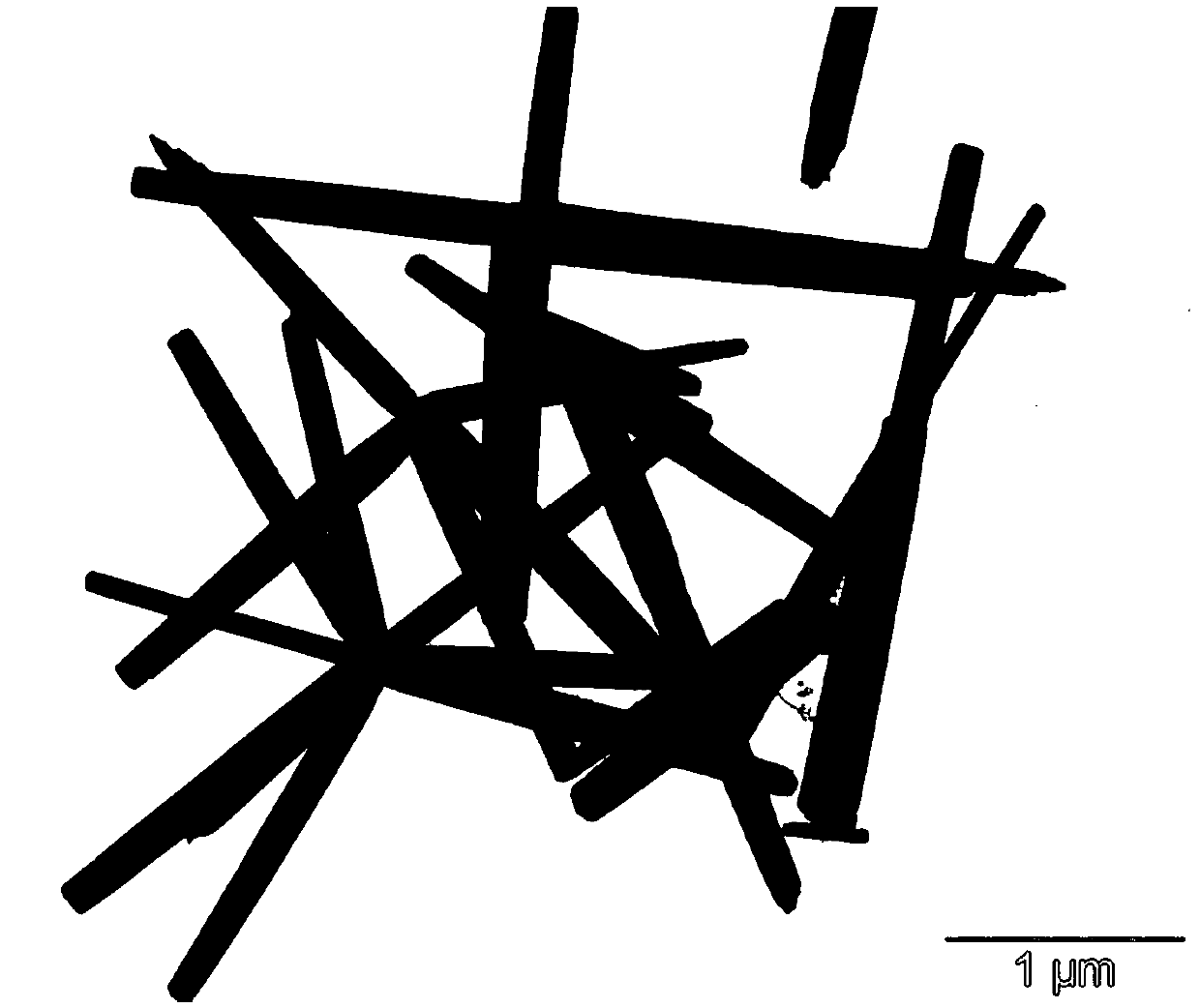

[0027] Zn(NO 3 ) 2 .6H 2 The mol ratio of O and hexamethylenetetramine is 1 / 1, and all the other are identical with embodiment 1. The Cu / ZnO catalyst was synthesized and named as Cu / ZnO-2. Such as figure 2 As shown, the obtained carrier has uniform nanorod morphology; the length is 2000-3000 nm; the diameter is 10-30 nm. The appearance of the catalyst is brown powder, and the XRD test results show that the average particle size of Cu particles is also between 10-25nm.

Embodiment 3

[0029] Zn(NO 3 ) 2 .6H 2 The mol ratio of O and hexamethylenetetramine is 1 / 0.5, and all the other are identical with embodiment 1. The Cu / ZnO catalyst was synthesized and named as Cu / ZnO-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com