Metal patterning method

A metal pattern and pattern structure technology, applied in metal material coating process, gaseous chemical plating, decorative arts, etc., can solve the problem of destroying the direct contact between the metal and the imprinted sample, increasing the edge roughness of the imprinting pattern, and affecting the pattern. Accuracy and other issues, to achieve the effect of reducing edge roughness, improving processing efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

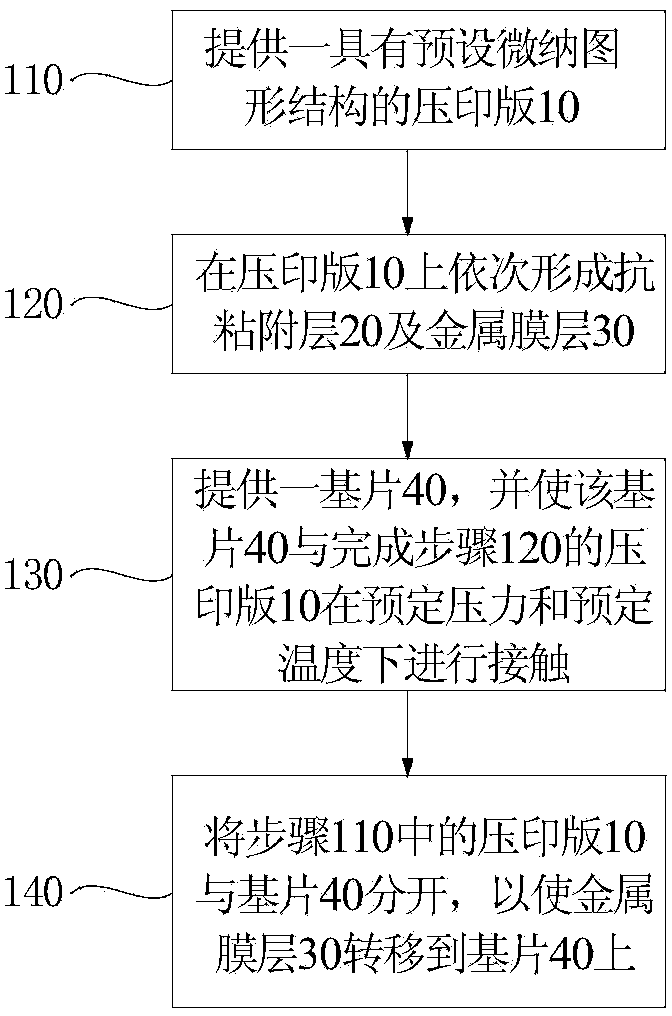

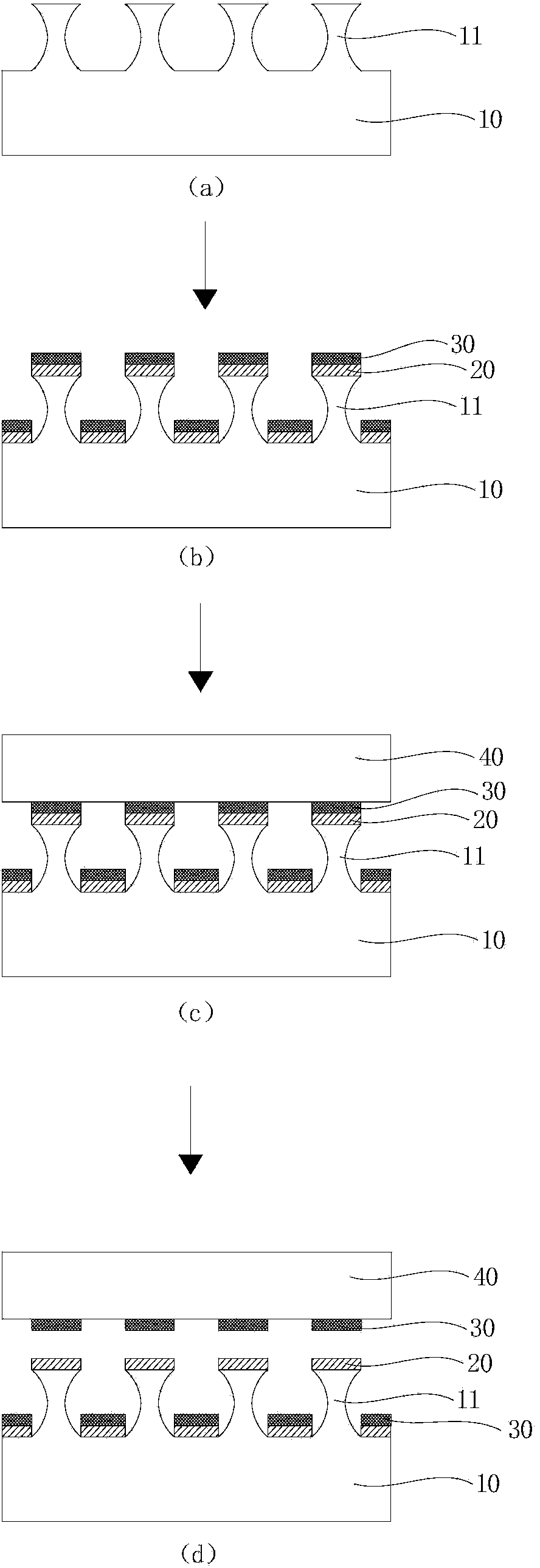

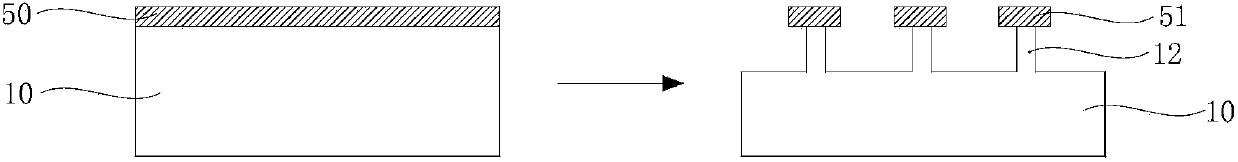

[0042] based on figure 1 and figure 2 The process flow diagram shown provides a silicon imprint plate with a preset micro-nano pattern structure and a substrate formed of polyethylene terephthalate (PET). First, using octafluorocyclobutane (C 4 f 8 ) gas at 300 watts power and 20 millitorr pressure to deposit an anti-adhesion layer formed by fluorocarbons on the silicon imprint plate; secondly, deposit a thickness of 100 nanometers on the anti-adhesion layer by electron beam evaporation process The gold film layer; then, use an optical microscope to align the silicon imprint plate with the substrate, and apply 5 standard atmospheric pressure to make the two compact, and raise the temperature to 100 degrees Celsius and keep it for 3 minutes; finally, naturally cool to room temperature And the pressure is removed to separate the silicon imprint plate from the substrate, thereby forming a nanometer metal structure (or called a metal pattern) on the substrate.

[0043] Figu...

Embodiment 2

[0048] based on figure 1 and figure 2 As shown in the process flow chart, a quartz imprint plate with a predetermined micro-nano pattern structure and a substrate formed of polyethylene terephthalate (PET) are provided. First, using octafluorocyclobutane (C 4 f 8 ) gas at 300 watts power and 20 millitorr pressure to deposit an anti-adhesion layer formed by fluorocarbons on the quartz imprint plate; secondly, deposit a thickness of 100 nanometers on the anti-adhesion layer by using electron beam evaporation process The aluminum film layer; then, use an optical microscope to align the quartz imprint plate with the substrate, and apply 10 standard atmospheres to make the two compact, and raise the temperature to 110 degrees Celsius and keep it for 3 minutes; finally, naturally cool to 40 Celsius and the pressure is removed to separate the quartz imprint plate from the substrate, thereby forming a nano-metal structure (or metal pattern) on the substrate.

[0049] Figure 7 I...

Embodiment 3

[0052] based on figure 1 and figure 2 The process flow diagram shown provides a silicon imprint plate with a predetermined micro-nano pattern structure (such as a one-dimensional grating pattern structure) and a substrate formed of polyethylene terephthalate (PET). First, using octafluorocyclobutane (C 4 f 8 ) gas at 300 watts power and 20 millitorr pressure to deposit an anti-adhesion layer formed by fluorocarbons on the silicon imprint plate; secondly, deposit a thickness of 100 nanometers on the anti-adhesion layer by electron beam evaporation process The aluminum film layer; then, use an optical microscope to align the silicon imprint plate with the substrate, and apply 10 standard atmospheric pressure to make the two compact, and raise the temperature to 110 degrees Celsius and keep it for 3 minutes; finally, naturally cool to 40 Celsius and the pressure is removed to separate the silicon imprint plate from the substrate, thereby forming a nano-metal structure on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com