Antimicrobial red glaze and preparation and application methods thereof

An anti-microbial and red technology, applied in the field of ceramic glazes, can solve the problems of inability to provide long-term inhibition and protection, ceramic surface damage, and reduced lifespan, and achieve bright and stable color, low firing temperature, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

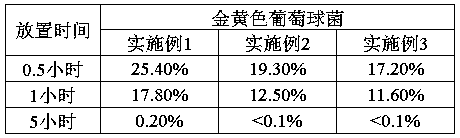

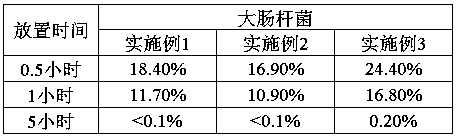

Examples

Embodiment 1

[0014] Mix 30 parts of potassium feldspar, 24 parts of muscovite, 7 parts of serpentine, 16 parts of talc, 11 parts of saltpeter, and 10 parts of manganese stone according to the weight ratio, and then through coarse crushing, fine crushing, grinding, and passing through a 200-mesh sieve; Add 5 parts of kojic acid dipalmitate, 9 parts of kojic acid, 0.3 parts of sodium sulfite, 2 parts of ferric chloride, 1 part of lead oxide, and 3 parts of copper oxide in a weight ratio to obtain a dry powder; mix the dry powder and water according to the weight ratio Mix 100:75, pass through a 300-mesh sieve, then add 2 parts of wood vinegar, mix evenly, and get an antimicrobial red glaze.

[0015] The glaze is applied to the surface of the formed tile body by dipping glaze, and it is fired in a kiln at 600°C for 7 hours to obtain a red tile with anti-microbial effect. It is stable, has strong decorative effect, and has inhibitory effect on the growth and reproduction of microorganisms.

Embodiment 2

[0017] By weight, 29 parts of potassium feldspar, 20 parts of muscovite, 5 parts of serpentine, 14 parts of talc, 10 parts of saltpeter, and 8 parts of manganese stone are mixed, followed by coarse crushing, fine crushing, grinding, and passing through a 200-mesh sieve; Add 7 parts of kojic acid dipalmitate, 12 parts of kojic acid, 0.4 part of sodium sulfite, 4 parts of ferric chloride, 1 part of lead oxide, and 5 parts of copper oxide in a weight ratio to obtain a dry powder; mix the dry powder and water according to the weight ratio Mix 100:68, pass through a 300-mesh sieve, add 5 parts of wood vinegar, mix evenly, and get antimicrobial red glaze.

[0018] The glaze is applied to the surface of the formed tile body by dipping glaze, and it is fired in a kiln at 650°C for 8 hours to obtain a red tile with anti-microbial effect. It is stable, has strong decorative effect, and has inhibitory effect on the growth and reproduction of microorganisms.

Embodiment 3

[0020] By weight, 26 parts of potassium feldspar, 21 parts of muscovite, 6 parts of serpentine, 13 parts of talc, 11 parts of saltpeter, and 7 parts of manganese stone are mixed, followed by coarse crushing, fine crushing, grinding, and passing through a 200-mesh sieve; Add 8 parts of kojic acid dipalmitate, 11 parts of kojic acid, 0.6 parts of sodium sulfite, 3.5 parts of ferric chloride, 1.5 parts of lead oxide, and 4.5 parts of copper oxide in a weight ratio to obtain a dry powder; mix the dry powder and water according to the weight ratio Mix 100:68, pass through a 300-mesh sieve, add 6 parts of wood vinegar, mix evenly, and get antimicrobial red glaze.

[0021] The glaze is applied to the surface of the formed tile body by dipping glaze, and it is fired in a kiln at 680°C for 7.5 hours to obtain a red tile with anti-microbial effect. It is stable, has strong decorative effect, and has inhibitory effect on the growth and reproduction of microorganisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com