A method and system for feeding thin sludge into a kiln

A sludge and cement kiln technology, applied in sludge treatment, separation methods, pyrolysis treatment of sludge, etc., can solve the problems of worsening combustion conditions, drop in cement kiln temperature, increase in operating costs, etc., and reduce nitrogen oxides. Emissions, preventing local temperature drop, ensuring yield and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

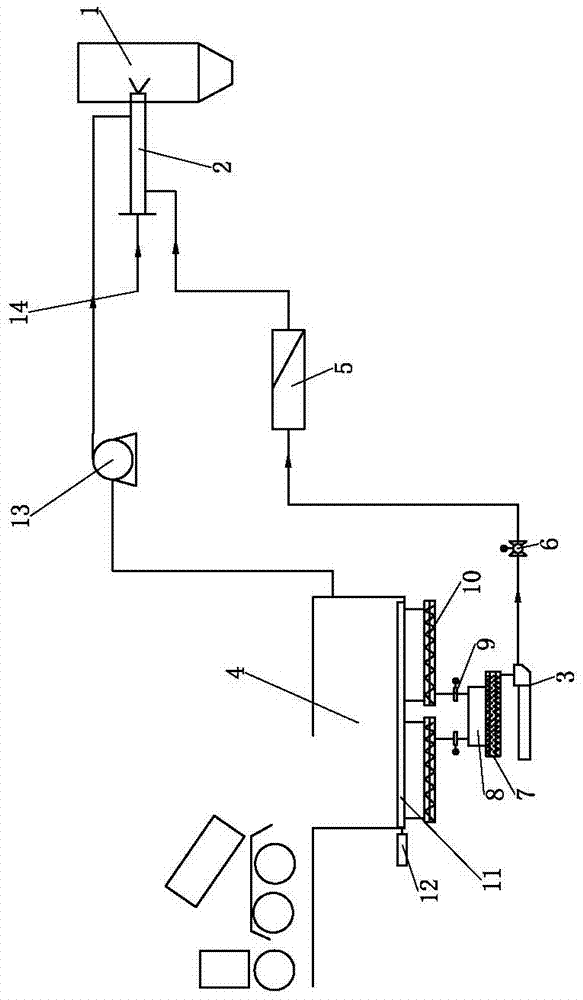

[0066] Such as figure 1 As shown, a method for introducing thin sludge into the kiln provided by this embodiment is to spray the thin sludge into the calciner in the form of mist.

[0067] From figure 1 It can be seen from the figure that the thin sludge is unloaded into the steel structure sludge bin 1 through a truck dedicated to transporting thin sludge, and the inner bottom of the sludge bin 1 is installed with a hydraulic cylinder 12 and a carriage 11 driven by the hydraulic cylinder 12 The broken arch device, through the horizontal reciprocating movement of the broken arch device, pushes the thin sludge to the middle unloading link to avoid bridging phenomenon of the thin sludge in the sludge bin 4, and the thin sludge passes through the bottom of the sludge bin 4 The single screw feeder 10 in the middle is unloaded outside the warehouse. A valve 9 is installed at an orthogonal position below the outlet of the single screw feeder 10, and the thin sludge enters the slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com