A method for preparing slow-release fertilizer by inorganic secondary adsorption

A secondary adsorption and slow-release fertilizer technology, applied in the direction of nitrate fertilizers, fertilizer mixtures, nitrogen fertilizers, etc., can solve the problems of difficult preparation and high cost of slow-release fertilizers, simplify the preparation process, improve soil water shortage, slow down good release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

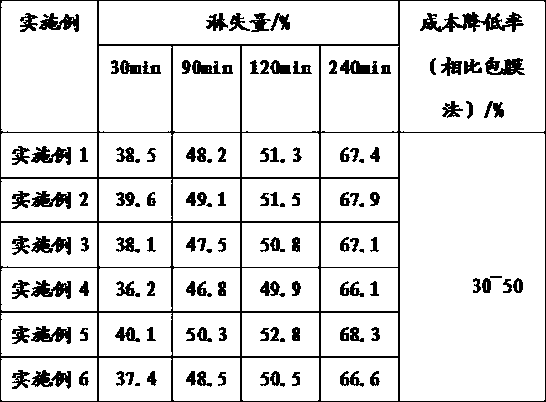

Examples

example 1

[0037] First add 3kg of attapulgite and 2kg of bentonite into a low-speed mixer, add 245mL of absolute ethanol as a dispersant, and stir for 2 hours at a speed of 40r / min. Then add 35kg of potassium nitrate powder, continue to stir for 20min, then add 70mL of tetraethyl orthosilicate, continue to stir for 2h. With above-mentioned similar method and proportioning, with 2kg attapulgite and 2kg bentonite, with deionized water as dispersant, 6kg calcium phosphate and 6kg calcium hydrogen phosphate are absorbed; With 3kg attapulgite and 2kg bentonite, with tetrachloro Use carbonized carbon as a dispersant to absorb 15kg of urea. Then the obtained fertilizers were filtered separately, dried in a vacuum oven, and crushed to 60-100 mesh. Then take 8kg of white carbon black and 8kg of diatom powder, add 0.4kg of 3-aminopropyltriethoxysilane, and mix them at high speed. Then take 8kg of expanded perlite, first heat and expand, then pretreat with ammonia water after cooling, then add 0...

example 2

[0039] First add 3kg of attapulgite and 3kg of bentonite to a low-speed mixer, add 280mL of absolute ethanol as a dispersant, and stir for 2 hours at a speed of 40r / min. Then add 40kg of potassium nitrate powder, continue to stir for 20min, then add 40mL of ethyl orthosilicate, continue to stir for 3h. With above-mentioned similar method and proportioning, with 3kg attapulgite and 2kg bentonite, with deionized water as dispersant, 6kg calcium phosphate and 5kg calcium hydrogen phosphate are adsorbed; With 2kg attapulgite and 2kg bentonite, with tetrachloride Carbonization is used as a dispersant to absorb 14kg of urea. Then the obtained fertilizers were filtered separately, dried in a vacuum oven, and crushed to 60-100 mesh. Then take 7kg of white carbon black and 6kg of diatom powder, add 0.3kg of 3-aminopropyltriethoxysilane, and mix at high speed. Then take 7kg of expanded perlite, first heat and expand, then pretreat with ammonia water after cooling, then add 0.2kg of 3-...

example 3

[0041] First add 3kg of attapulgite and 2kg of bentonite into a low-speed mixer, add 301mL of absolute ethanol as a dispersant, and stir for 2 hours at a speed of 40r / min. Then add 43kg of potassium nitrate powder, continue to stir for 20min, then add 45mL of ethyl orthosilicate, continue to stir for 4h. With above-mentioned similar method and proportioning, with 3kg attapulgite and 2kg bentonite, with deionized water as dispersant, 5kg calcium phosphate and 5kg calcium hydrogen phosphate are adsorbed; With 3kg attapulgite and 2kg bentonite, with tetrachloride Use carbonized carbon as a dispersant to absorb 12kg of urea. Then the obtained fertilizers were filtered separately, dried in a vacuum oven, and crushed to 60-100 mesh. Then take 7kg of white carbon black and 8kg of diatom powder, add 0.3kg of 3-aminopropyltriethoxysilane, and mix at high speed. Then take 6kg of expanded perlite, first heat and expand, then pretreat with ammonia water after cooling, then add 0.2kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com