Organosilicone-acrylate nanometer emulsion and preparation method thereof

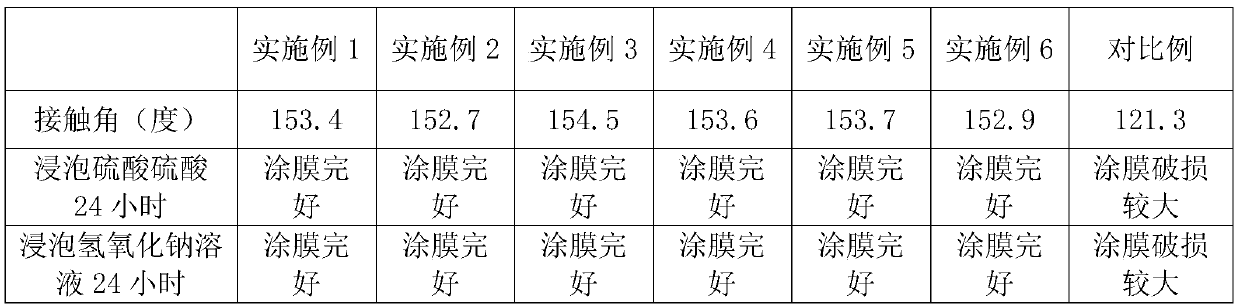

A technology of acrylate and nanoemulsion, applied in the field of nanoemulsion, can solve the problems of unsatisfactory water resistance, poor acid and alkali resistance, and failure to achieve superhydrophobic effect, etc., to improve acid and alkali resistance, reduce damage, and contact angle Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Organosilicon-acrylic acid ester nanoemulsion, the following steps are made: (1) the sodium hydroxide solution that concentration is 0.4mol / L is added dropwise in the zinc nitrate solution that concentration is 0.2mol / L, sodium hydroxide solution and zinc nitrate The volume ratio of the solution is 1:1, under nitrogen protection, adjust the pH value to 6.5, stir at 5°C for 40 minutes, age for 3 hours, repeatedly wash with distilled water after suction filtration, and obtain nano-zinc hydroxide after drying;

[0026] (2) the nano-zinc hydroxide that step (1) obtains is added together with DBS solution, water in the stainless steel reaction kettle that lining is polytetrafluoroethylene, and the weight ratio of nano-zinc hydroxide, DBS, water is 1:10: 25. Adjust the pH value to 8.5, heat to 120°C, hydrothermally react for 7 hours, repeatedly wash with distilled water after suction filtration, grind after drying, and pass through a 200-mesh sieve to obtain organic nano-zinc ...

Embodiment 2

[0030] Organosilicon-acrylic acid ester nanoemulsion, the following steps are made: (1) the sodium hydroxide solution that concentration is 0.4mol / L is added dropwise in the zinc nitrate solution that concentration is 0.2mol / L, sodium hydroxide solution and zinc nitrate The volume ratio of the solution is 1:1, under nitrogen protection, adjust the pH value to 6.5, stir at 5°C for 40 minutes, age for 3 hours, repeatedly wash with distilled water after suction filtration, and obtain nano-zinc hydroxide after drying;

[0031] (2) the nano-zinc hydroxide that step (1) obtains is added together with DBS solution, water in the stainless steel reaction kettle that lining is polytetrafluoroethylene, and the weight ratio of nano-zinc hydroxide, DBS, water is 1:10: 25. Adjust the pH value to 8.5, heat to 120°C, hydrothermally react for 7 hours, repeatedly wash with distilled water after suction filtration, grind after drying, and pass through a 200-mesh sieve to obtain organic nano-zinc ...

Embodiment 3

[0035] Organosilicon-acrylic acid ester nanoemulsion, the following steps are made: (1) the sodium hydroxide solution that concentration is 0.4mol / L is added dropwise in the zinc nitrate solution that concentration is 0.2mol / L, sodium hydroxide solution and zinc nitrate The volume ratio of the solution is 1:1, under nitrogen protection, adjust the pH value to 6.5, stir at 5°C for 40 minutes, age for 3 hours, repeatedly wash with distilled water after suction filtration, and obtain nano-zinc hydroxide after drying;

[0036] (2) the nano-zinc hydroxide that step (1) obtains is added together with DBS solution, water in the stainless steel reaction kettle that lining is polytetrafluoroethylene, and the weight ratio of nano-zinc hydroxide, DBS, water is 1:10: 25. Adjust the pH value to 8.5, heat to 120°C, hydrothermally react for 7 hours, repeatedly wash with distilled water after suction filtration, grind after drying, and pass through a 200-mesh sieve to obtain organic nano-zinc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com