Preparation method of monobutyl ether alcohol terminated polyester plasticizer

A monobutyl ether alcohol and polyester plasticizer technology, applied in the field of polymer material additives, can solve the problem of poor compatibility between nonanol structure and plastic molecules, low molecular weight of polyester, poor plasticizing effect, etc. problems, to achieve the effect of improving the scope of application, overcoming poor stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

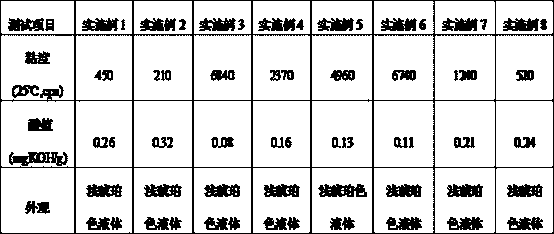

Embodiment 1

[0022] Embodiment 1 Take by weighing 236.2g succinic acid, 231.1g triethylene glycol, 2.34g stannous octoate and 37.4g toluene respectively and join in the esterification still of 1L, logical N 2 Protect, stir and heat up, when the toluene with water starts to reflux, start timing, the temperature of the effluent from the reflux gradually rises to 220°C, react for 8 hours, until no more water is produced, then add 222.2g of triethylene glycol monobutyl ether, and reflux to effluent When the temperature gradually rises to 220°C, continue to react for 6 hours, take samples to measure the acid value, when the measured acid value is 0.8mgKOH / g, cool down to 180°C, first extract the toluene under the vacuum degree of 2000Pa, then heat up to 210°C, The excess unreacted triethylene glycol monobutyl ether is distilled under reduced pressure at a vacuum degree of 500 Pa, and finally cooled and filtered to obtain a light amber liquid, which is triethylene glycol monobutyl ether-capped po...

Embodiment 2

[0023] Example 2 Weigh 250g of adipic acid, 129.7g of diethylene glycol, 0.38g of dibutyltin oxide and 4g of petroleum ether and add them to a 1L esterification kettle. 2 Protect, stir and heat up. When the petroleum ether starts to reflux with water, start timing, and the temperature of the effluent from the reflux gradually rises to 220 ° C. React for 6 hours until no more water is produced. Then add 198.2g of diethylene glycol monobutyl ether, from the reflux to The temperature of water gradually rises to 220°C, continue to react for 7 hours, take samples to measure the acid value, when the measured acid value is 0.9mgKOH / g, cool down to 180°C, extract petroleum ether at a vacuum degree below 2000Pa, and then heat up to 210°C , distill off excess unreacted diethylene glycol monobutyl ether under reduced pressure below 500 Pa, and finally cool and filter to obtain light amber liquid, which is diethylene glycol monobutyl ether-capped poly(diethylene glycol adipate) ) ester pl...

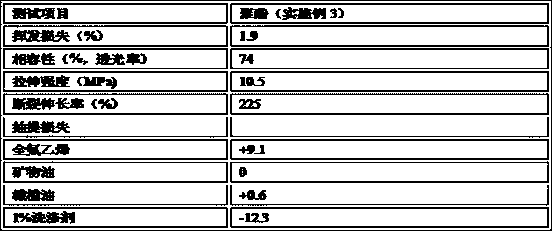

Embodiment 3

[0024] Example 3 Weigh 260g of glutaric acid, 347.5g of tetraethylene glycol, 0.3g of monobutyltin oxide and 9.1g of petroleum ether and add them to a 1L esterification kettle, and pass N 2 Protect, stir and heat up. When the petroleum ether starts to reflux with water, start timing. The temperature of the effluent from the reflux gradually rises to 220 ° C. React for 9 hours until no more water is produced. The temperature gradually rises to 220°C, and the reaction is continued for 5 hours. The acid value is measured by sampling. When the acid value is 0.7mgKOH / g, the temperature is lowered to 180°C, and the petroleum ether is first extracted at a vacuum degree of 2000Pa, and then the temperature is raised to 210°C. At a vacuum of 500Pa

[0025] Under reduced pressure, distill out excessive unreacted dipropylene glycol monobutyl ether, and finally cool and filter to obtain a light amber liquid, which is the poly(tetraethylene glycol glutarate) plasticizer terminated with dipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com