Environment-friendly ceramic simulating coating and spraying method thereof

A porcelain-like coating, an environmentally friendly technology, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor environmental compatibility, achieve strong adhesion, eliminate benzene emissions, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

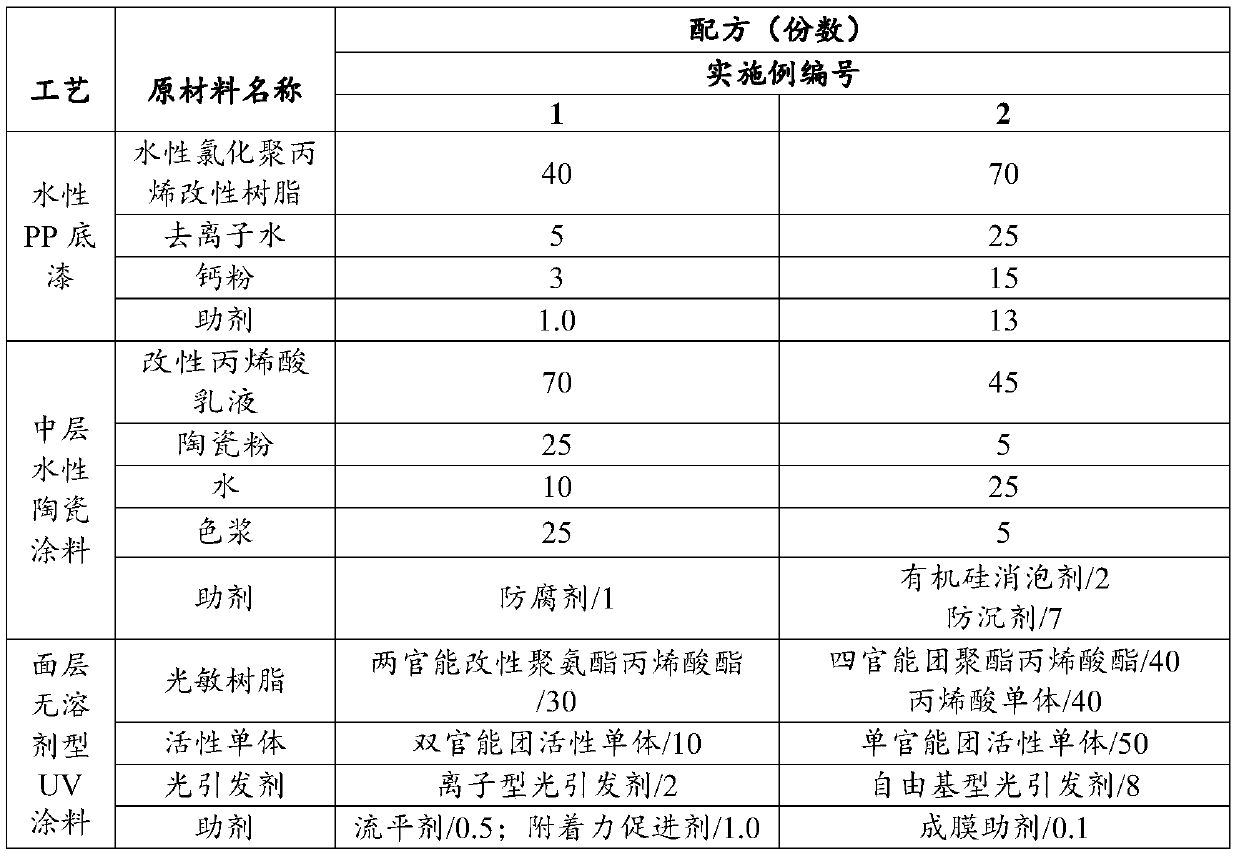

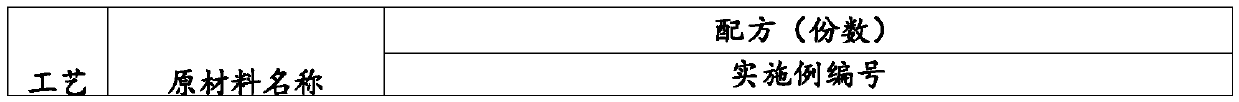

[0094] The raw material components of the environment-friendly porcelain-like paint provided in this example are as shown in Example Nos. 1-2 in Table 1.

[0095] Its spraying method comprises the following steps:

[0096] 1) Apply a water-based PP primer on the preform as a whole, dry the primer and apply a middle-layer water-based ceramic coating on its surface, and coat the surface with a solvent-free surface layer after drying the middle-layer water-based ceramic coating. UV coating;

[0097] The drying conditions are: heat curing at 60-80°C for 15-25 minutes or natural drying for more than 24 hours;

[0098] 2), drying the solvent-free UV coating on the surface layer;

[0099] The drying conditions are as follows: after heating and leveling the surface layer of UV coating at 50-65°C for 3-7 minutes, then the preform of the coated surface layer of solvent-free UV coating enters the light source area at a speed of 4-6m / min , curing time 6~10s, cumulative radiation 400~90...

Embodiment 3~5

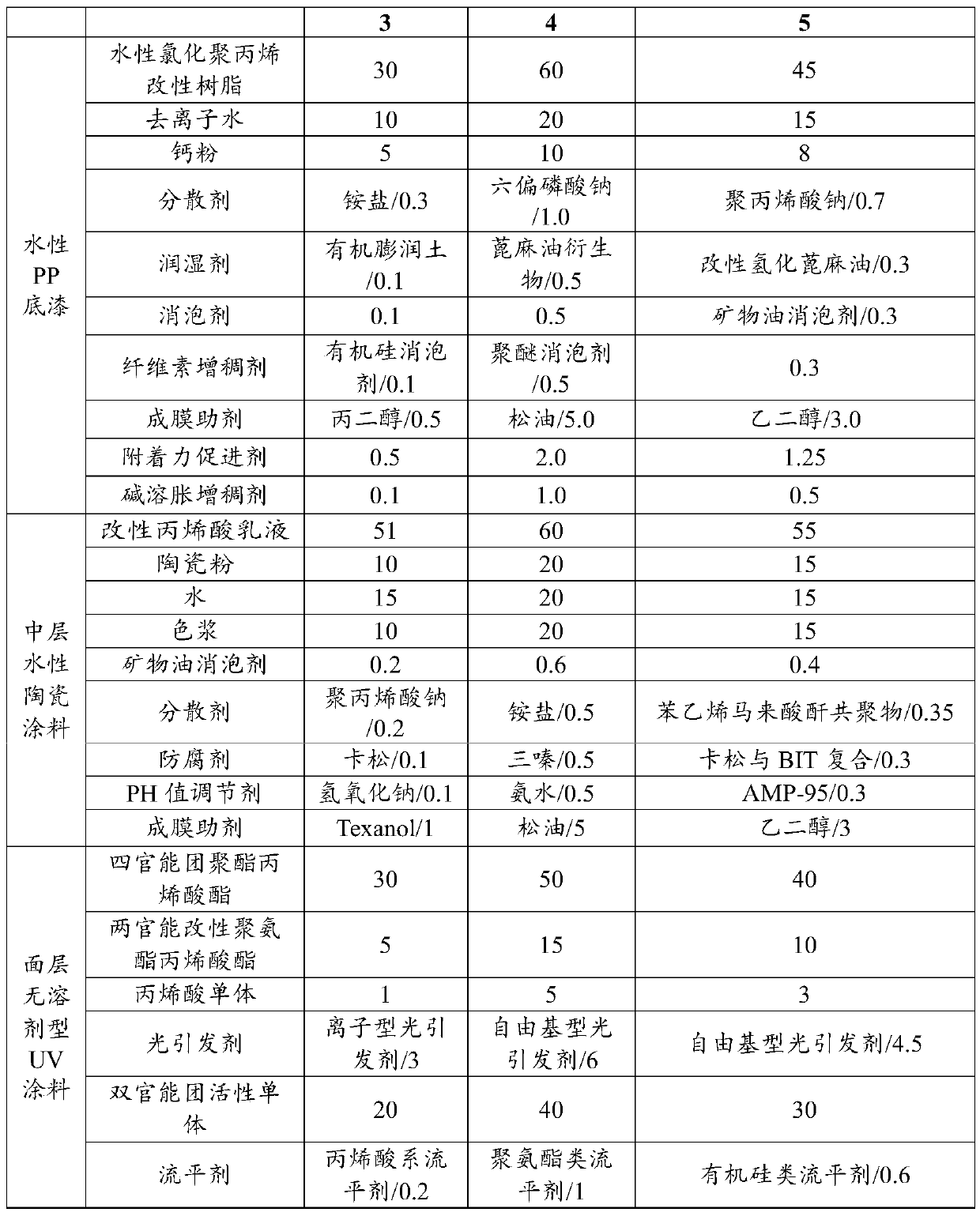

[0101] The raw material components of the environment-friendly porcelain-like paint provided in this example are as shown in Example numbers 3-5 in Table 1.

[0102] Use a small blade to clean the burrs of the injection-molded PP material flower pots, and then use a cleaning agent to clean the oil stains on the surface of the flower pots. Then spray PP primer with a film thickness of 5-10u, bake at 60-70°C for 20-25 minutes, and proceed to the next process after cooling;

[0103] Intermediate coat one or more layers of intermediate water-based ceramic paint, spray it evenly on the PP primer in the form of mist, and then scatter it on the freshly sprayed base color in the form of dots, let it naturally Produce the effect of flowing glaze, dry naturally for more than 24 hours;

[0104] It is best to spray a surface layer of solvent-free UV paint on it, heat and level the surface layer of solvent-free UV paint at 50-65°C for 3-7 minutes, and then apply the surface layer of solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com