A kind of aluminum alloy anodic oxidation color treatment method

A technology of anodizing and treatment method, applied in the field of aluminum alloy surface treatment, aluminum alloy anodizing coloring treatment, can solve the problems of breakdown parts, film overheating, dissolution, etc., to avoid concentrated heat generation, high light fastness, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: An aluminum alloy anodic oxidation coloring treatment method of the present invention uses direct current, low voltage power supply loading mode, uses sulfuric acid solution as the main component of the electrolyte, adopts the method of organic dye adsorption coloring, and uses organic dye as the dyeing agent For anodizing, the specific steps are:

[0030] (1) Cut the 2024 aluminum alloy raw material into a square sample with a size of 15mm×15mm×10mm;

[0031] (2) Pretreatment: Grind sequentially with 240# to 1200# sandpaper, polish the aluminum alloy surface smooth, put it in ethanol for cleaning and degreasing treatment; apply a little polishing paste on the surface of the aluminum alloy sample, and perform mechanical polishing treatment; sequentially carry out alkali Washing, pickling, and then rinsing and drying with deionized water to obtain a clean and scratch-free aluminum alloy sample;

[0032] (3) Anodizing treatment: Anodize the aluminum alloy s...

Embodiment 2

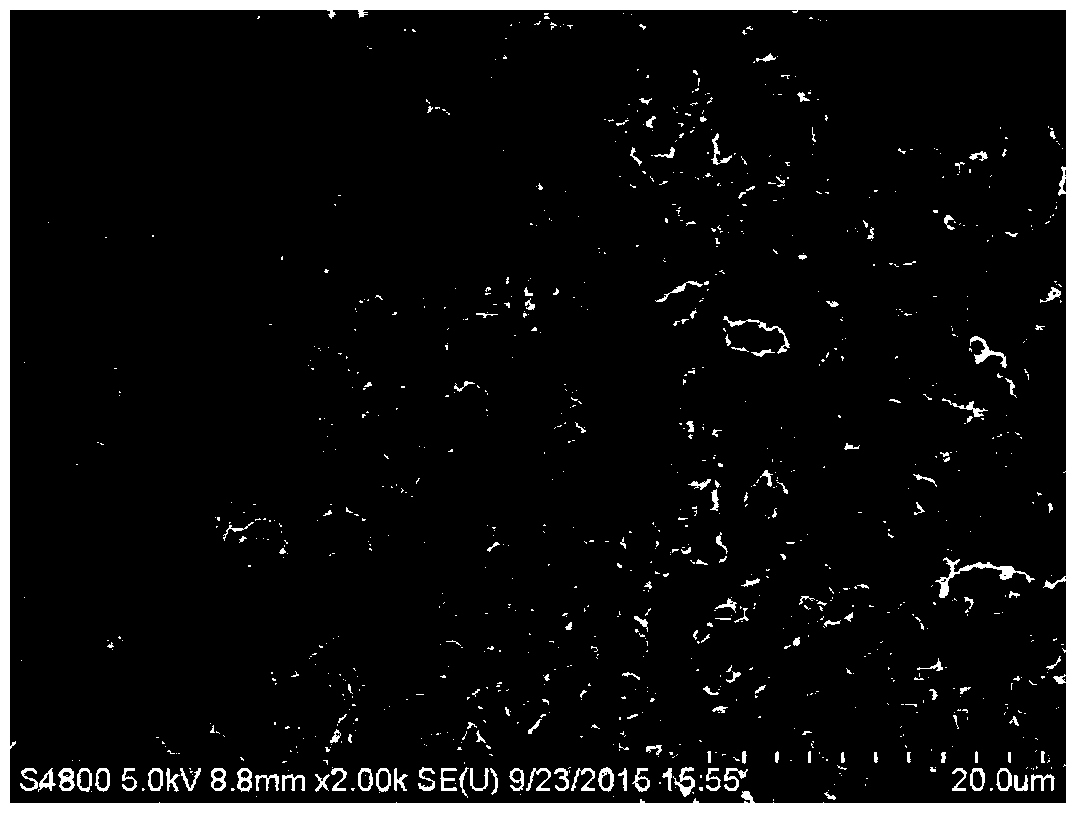

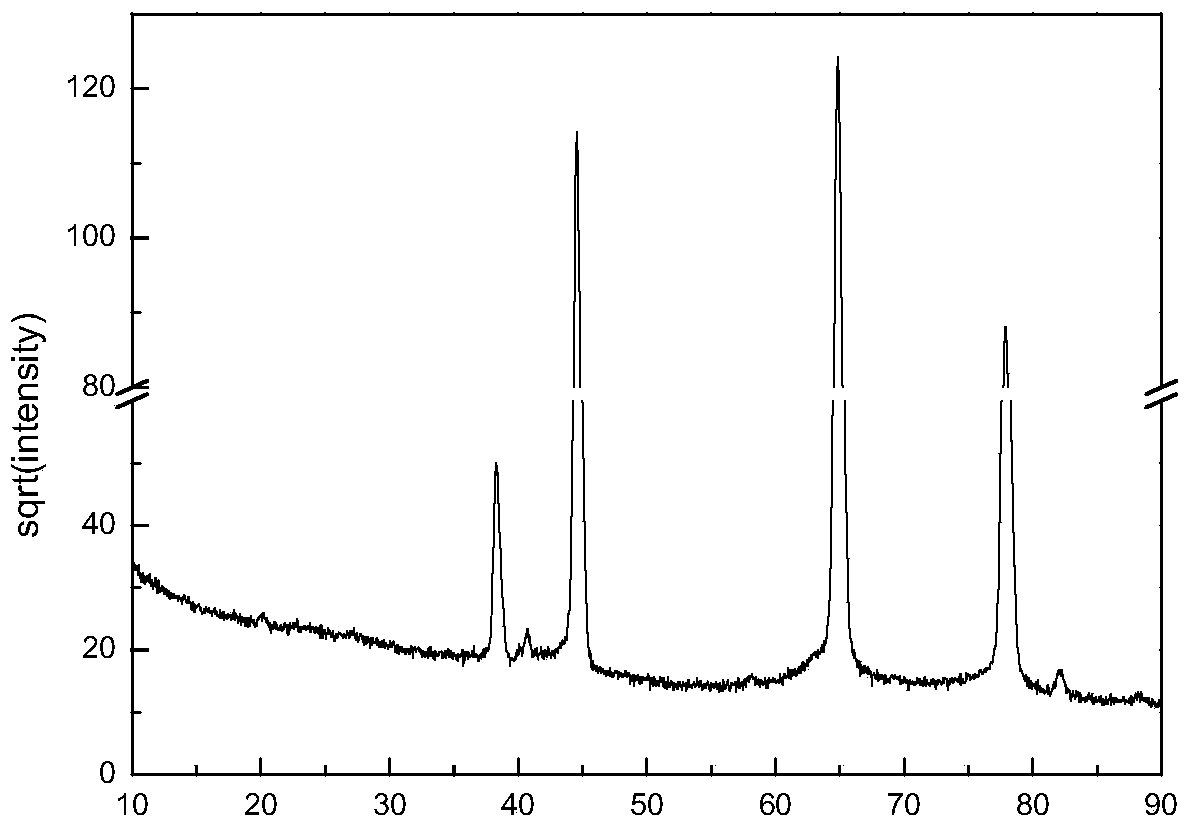

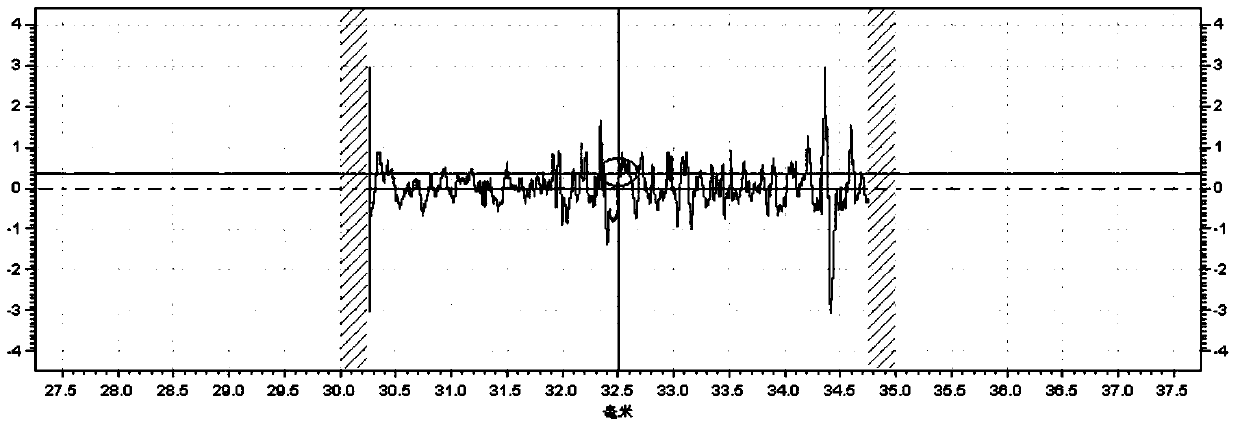

[0036] Embodiment 2: The difference between this example and Example 1 is: in the anodizing treatment process of this example: the concentration of sulfuric acid is 150g / L, and the concentration of aluminum sulfate is 18g / L; The time is 10000s; the temperature is at normal temperature; after the treatment is completed, it is washed and dried with deionized water immediately to obtain the following Figure 1-3 The surface of the anodized aluminum film sample with high quality and crystalline structure is shown; the roughness value Ra of the anodized aluminum film is less than 0.5, which is μm.

[0037] Coloring treatment: Fully dissolve the organic dye, heat to 45°C and keep it warm, put the prepared anodized aluminum film sample into it, soak for 28 minutes to form a dyed sample, and the surface of the processed sample is dyed with various colors. The parameters of the organic dye adsorption coloring process are as follows: the dyeing solution is: X-type organic dye 3g / L; the ...

Embodiment 3

[0039] Embodiment 3: The difference between this example and Example 1 is: in the anodizing treatment process of this example: the concentration of sulfuric acid is 200g / L, and the concentration of aluminum sulfate is 10g / L; The time is 9000s; the temperature is at normal temperature; after the treatment is completed, it is washed and dried with deionized water immediately to obtain the following: Figure 1-3The surface of the anodized aluminum film sample with high quality and crystalline structure is shown; the roughness value Ra of the anodized aluminum film is less than 0.5, which is μm.

[0040] Coloring treatment: Fully dissolve the organic dye, heat to 45°C and keep it warm, put the prepared anodized aluminum film sample into it, soak for 20 minutes to form a dyed sample, and the surface of the processed sample is dyed with various colors. The parameters of the organic dye adsorption coloring process are as follows: the dyeing solution is: X-type organic dye 4g / L; the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com