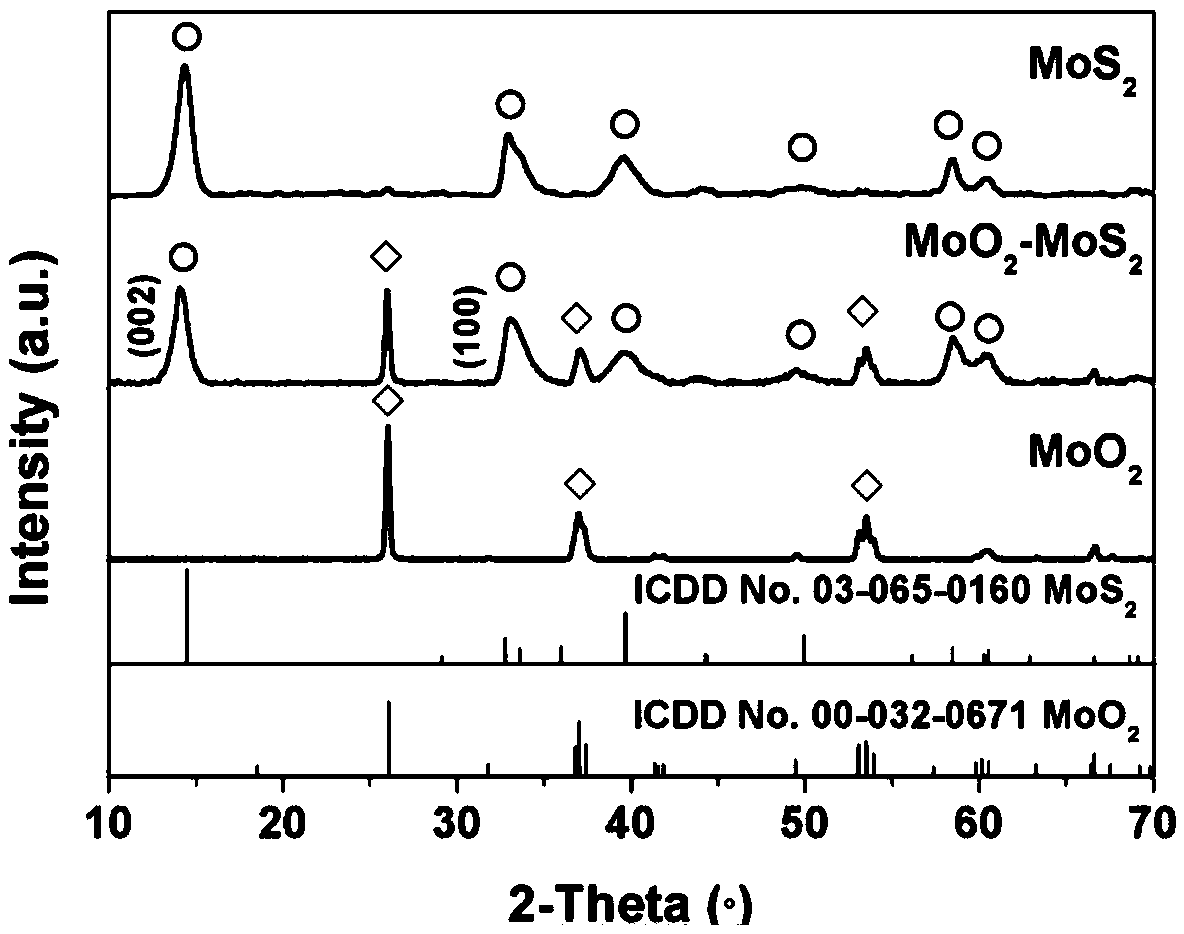

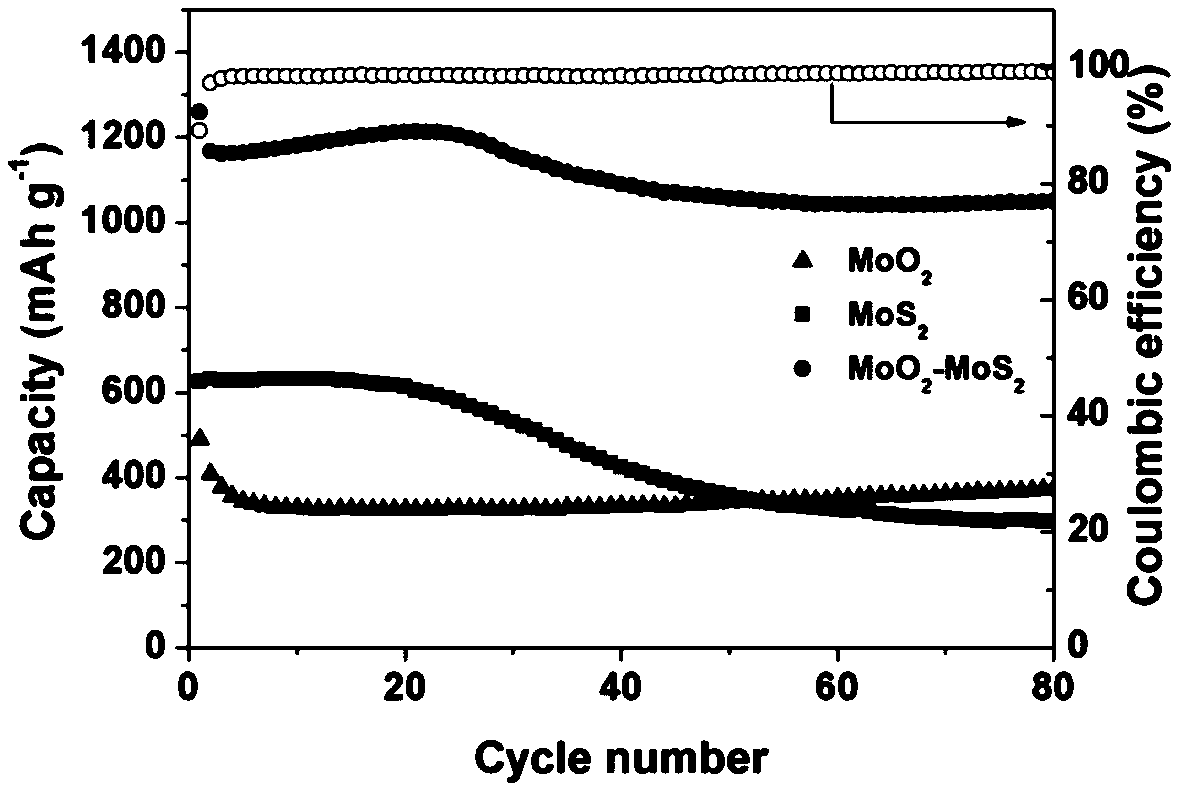

Three-dimensional core-shell structure MoO2-MoS2 lithium ion battery cathode material and preparing method thereof

A lithium-ion battery, moo2-mos2 technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of poor product repeatability and uniformity, unfavorable large-scale production, and difficult process control, and improve cycle stability. The effect of high conductivity and conductivity, short preparation cycle and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

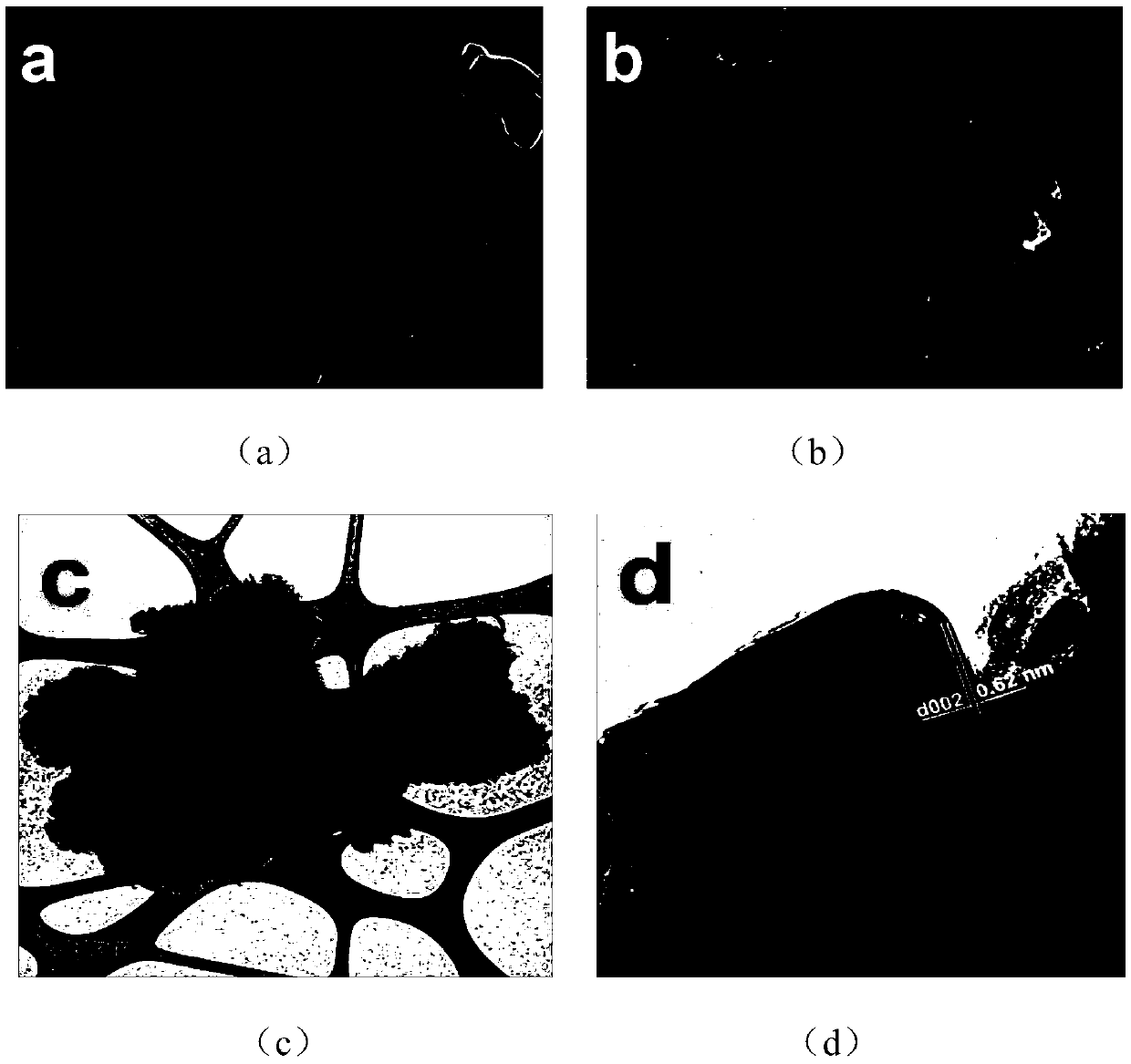

[0029] A three-dimensional core-shell structure MoO 2 -MoS 2 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0030] 1) Precursor MoO 2 preparation of

[0031] ①Weigh 1.50g of MoO 3 Place in a porcelain boat, and place the porcelain boat in a tubular atmosphere furnace;

[0032] ②At 5°C min -1 The heating rate was increased to 400°C, and the temperature was kept for 3 hours. During the reaction process, the mixed gas (volume ratio V(H 2 :Ar)=1:1), the volume flow rate is maintained at 50 sccm;

[0033] ③ After the reaction, cool to room temperature. During this process, Ar gas is always introduced, and the volume flow rate is kept at 5 sccm; the product is washed with deionized water for 3 times, and vacuum-dried at 60°C for 12 hours to obtain the product MoO 2 .

[0034] 2) MoO 2 -MoS 2 preparation of

[0035] ①Weigh the mass ratio m(MoO 2 :S)=0.50:1.00 precursor MoO2 and S powder, mix evenly and place in ...

Embodiment 2

[0042] A three-dimensional core-shell structure MoO 2 -MoS 2 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0043] 1) Precursor MoO 2 preparation of

[0044] ①Weigh 1.60g of MoO 3 Place in a porcelain boat, and place the porcelain boat in a tubular atmosphere furnace;

[0045] ②At 6°C min -1 The heating rate was raised to 450°C, and the temperature was kept for 2.5 hours. During the reaction, the mixed gas (volume ratio V(H 2 :Ar)=1:1), the volume flow rate is maintained at 60 sccm;

[0046] ③ After the reaction, cool to room temperature. During this process, Ar gas is always introduced, and the volume flow rate is kept at 6 sccm; the product is washed with deionized water for 3 times, and vacuum-dried at 65°C for 11 hours to obtain the product MoO 2 .

[0047] 2) MoO 2 -MoS 2 preparation of

[0048] ①Weigh the mass ratio m(MoO 2 :S)=0.50:1.10 precursor MoO 2 and S powder, mix evenly and place in a porce...

Embodiment 3

[0052] A three-dimensional core-shell structure MoO 2 -MoS 2 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0053] 1) Precursor MoO 2 preparation of

[0054] ①Weigh 1.70g of MoO 3 Place in a porcelain boat, and place the porcelain boat in a tubular atmosphere furnace;

[0055] ②At 7°C min -1 The heating rate was raised to 500°C, and the temperature was kept for 2 hours. During the reaction process, the mixed gas (volume ratio V(H 2 :Ar)=1:1), the volume flow rate is maintained at 70 sccm;

[0056] ③ After the reaction, cool to room temperature. During this process, Ar gas is always introduced, and the volume flow rate is kept at 7 sccm; the product is washed 4 times with deionized water, and vacuum-dried at 70°C for 10 hours to obtain the product MoO 2 .

[0057] 2) MoO 2 -MoS 2 preparation of

[0058] ①Weigh the mass ratio m(MoO 2 :S)=0.50:1.20 precursor MoO 2 and S powder, mix evenly and place in a por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com