Preparation method of honeycombed graphene/tungsten carbide/platinum composite electrocatalyst and application thereof

A tungsten carbide composite, electrocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, circuits, etc., can solve the problem of affecting the conductivity and stability, not high enough, chemically reducing the conductivity and stability of graphene oxide Insufficient conductivity and other problems, to achieve the effect of strong electrical conductivity and stability, high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

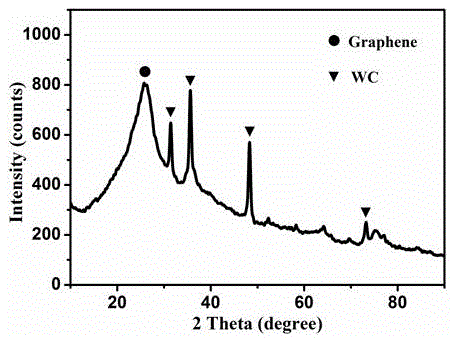

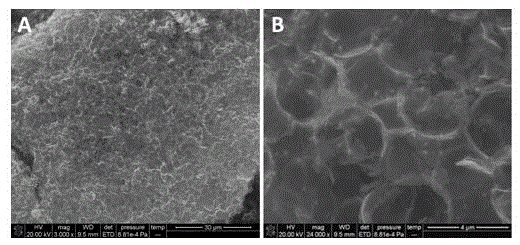

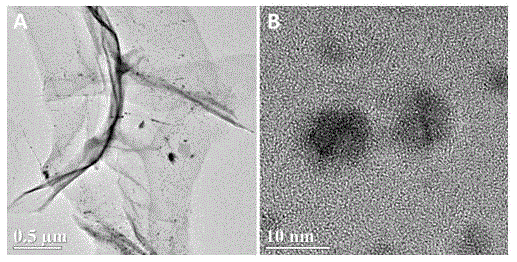

[0043] Weigh 0.5g of graphene oxide, 2.0g of polymethyl methacrylate spherical template material (average diameter 3μm) and 0.1g of ammonium tungstate (calculated as W metal) and evenly disperse them in deionized water; Synchronous stirring and heating drying on a magnetic stirrer, the stirring rate is 500 rpm, the heating temperature is 80°C, and dried to a viscous slurry; the above slurry is placed in a high-temperature furnace and heated under a high-purity nitrogen atmosphere. The heating temperature is 900°C, the heating time is 2h, and the heating rate is 5°C / min; the above-mentioned heat-treated products are further pulverized and sieved to obtain a honeycomb "graphene / WC" composite.

[0044] The honeycomb "graphene / WC" composite prepared by the above method, wherein the size of the graphene honeycomb structure is about 3 μm, WC accounts for 26.7% of the total weight of the composite, the honeycomb "graphene / WC" composite The specific surface area is 526m 2 g -1 , the...

Embodiment 2

[0047] Weigh 0.5g of graphene oxide, 2.0g of polymethylmethacrylate spherical template material (average diameter 5μm) and 0.2g of ammonium tungstate (calculated as W metal) and evenly disperse in deionized water; Synchronous stirring and heating drying on a magnetic stirrer, the stirring rate is 500 rpm, the heating temperature is 80°C, and dried to a viscous slurry; the above slurry is placed in a high-temperature furnace and heated under a high-purity nitrogen atmosphere. The heating temperature is 900°C, the heating time is 2h, and the heating rate is 5°C / min; the above-mentioned heat-treated products are further pulverized and sieved to obtain a honeycomb "graphene / WC" composite.

[0048] Prepared "honeycomb graphene / WC" composite, wherein the size of the graphene honeycomb structure is about 5 μm, WC accounts for 38.5% of the total weight of the composite, and the specific surface area of the honeycomb "graphene / WC" composite is 488m 2 g -1 , the conductivity is 1150...

Embodiment 3

[0050] Weigh 0.5g of graphene oxide, 2.0g of polymethyl methacrylate spherical template material (average diameter 2μm) and 0.3g of ammonium tungstate (calculated as W metal) and evenly disperse in deionized water; Synchronous stirring and heating drying on a magnetic stirrer, the stirring rate is 500 rpm, the heating temperature is 80°C, and dried to a viscous slurry; the above slurry is placed in a high-temperature furnace and heated under a high-purity nitrogen atmosphere. The heating temperature is 900°C, the heating time is 2h, and the heating rate is 5°C / min; the above-mentioned heat-treated products are further pulverized and sieved to obtain a honeycomb "graphene / WC" composite.

[0051] The prepared honeycomb "graphene / WC" composite body, wherein the size of the graphene honeycomb structure is about 2 μm, WC accounts for 52.7% of the total weight of the composite body, and the specific surface area of the honeycomb "graphene / WC" composite body is 413m 2 g -1 , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com