An extracting, separating and purifying method of salvianolic acid A and a preparing method of salvianolic acid salts

A technology for separation and purification of salvianolic acid, which is applied in the field of medicine, can solve the problems of extremely high requirements for purified samples, low yield of salvianolic acid A, and high cost of reversed-phase silica gel, and achieves time-saving purification methods, low cost, and high production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for purifying, separating and purifying salvianolic acid A, the steps are as follows:

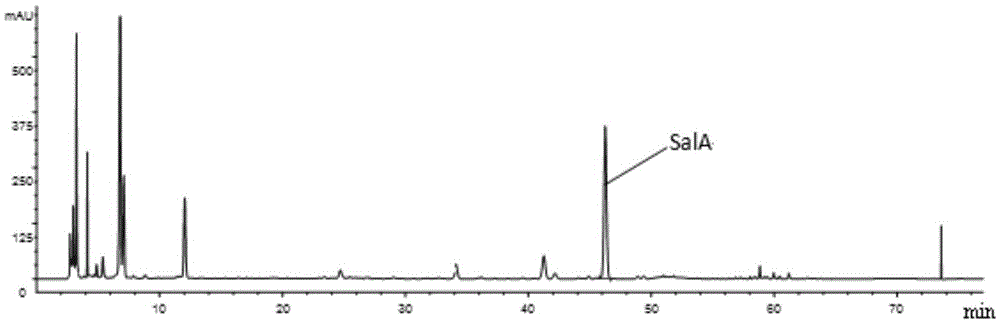

[0058] With reference to the method disclosed in Chinese patent document CN102793745A (Application No.: 201210334295.7), Salvia miltiorrhiza is pretreated; the HPLC figure of Salvia miltiorrhiza after treatment is as follows figure 1 shown.

[0059] (1) Solvent extraction: take the processed Salvia miltiorrhiza as raw material, get 500g, add 12 times the amount of 75wt% ethanol solution as the extraction solvent and carry out ultrasonic extraction, the ultrasonic temperature is 30 ° C, the number of times of extraction is 3 times, each 30 minutes, Remove the dregs and combine the filtrates.

[0060] (2) Solvent extraction: the above-mentioned filtrate is concentrated under reduced pressure to no ethanol, diluted with water, the amount of water added is 2 times the weight of the concentrated solution, and then extracted twice with equal volume of dichloromethane to degrease,...

Embodiment 2

[0069] A method for purifying, separating and purifying salvianolic acid A, the steps are as follows:

[0070] Pretreatment of Salvia miltiorrhiza with reference to the method disclosed in Chinese patent document CN102793745A (application number: 201210334295.7);

[0071] (1) Solvent extraction: take the processed salvia miltiorrhiza as raw material, get 500g, add 8 times the amount of 75wt% ethanol solution as the extraction solvent and carry out ultrasonic extraction, the ultrasonic temperature is 30 ° C, the number of times of extraction is 4 times, each 30 minutes, remove dregs, combined filtrate.

[0072] (2) Solvent extraction: Concentrate the above filtrate under reduced pressure to no ethanol, dilute with water, the amount of water added is twice the weight of the concentrated solution, and then extract and degrease with an equal volume of dichloromethane until the dichloromethane layer is light in color, discard The dichloromethane layer was adjusted to pH=1-2 with 2...

Embodiment 3

[0081] It is basically the same as Example 1, except that step (1) adds 10 times the amount of 75wt% ethanol solution as the extraction solvent for ultrasonic extraction, the ultrasonic temperature is 50°C, and the extraction times are 3 times, each time 40 minutes, to obtain salvianol Acid A was 92.4% pure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com