Ionic liquid micro-array monomolecular-layer fluorescent sensing film, and preparation method and application thereof

A single molecular layer, fluorescent sensing technology, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, analytical materials, etc., can solve the problem of limiting applications, affecting the response speed, sensitivity and stability of chemical sensors, and uneven distribution of fluorescent species Molecular permeability and other problems, to achieve long service life, solve the effects of poor stability and permeability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

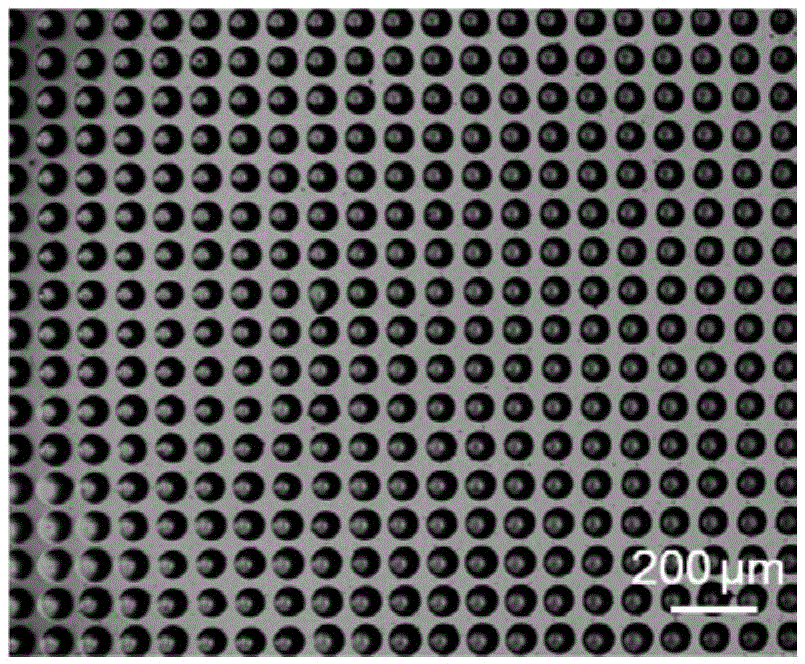

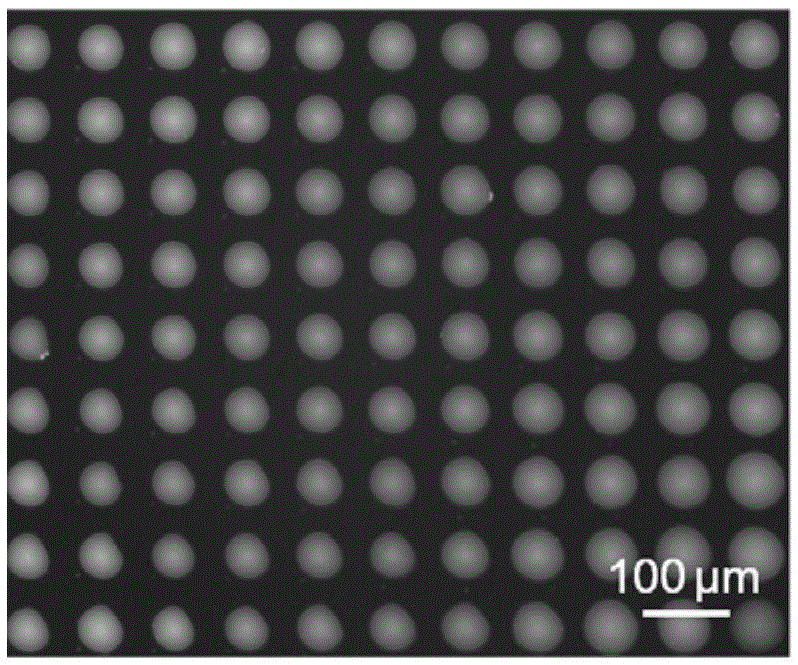

[0026] 1. Preparation of polydimethylsiloxane template with planar structure

[0027] Mix the liquid polydimethylsiloxane prepolymer with the corresponding curing agent (184 can glue product of Dow Corning Company) according to the mass ratio of 9:1, and after vacuum degassing at 30°C for 30 minutes, pour it into an orderly pattern In a mold composed of a melted photoresist plate and flat glass, cure at 80°C for 8 hours, cool to room temperature naturally, carefully peel off the cured PDMS film layer from the mold, and cut off the four sides without the patterned area to obtain PDMS templates with microscopically ordered surface structures.

[0028] 2. Preparation of gold substrates with hydrophilic and hydrophobic micro-domains

[0029]Mix 30% hydrogen peroxide aqueous solution with 98% sulfuric acid in a volume ratio of 3:7 to prepare a lotion; wash the silicon wafer with distilled water and ethanol, dry it and immerse it in the lotion, heat and wash solution to 80°C, acti...

Embodiment 2

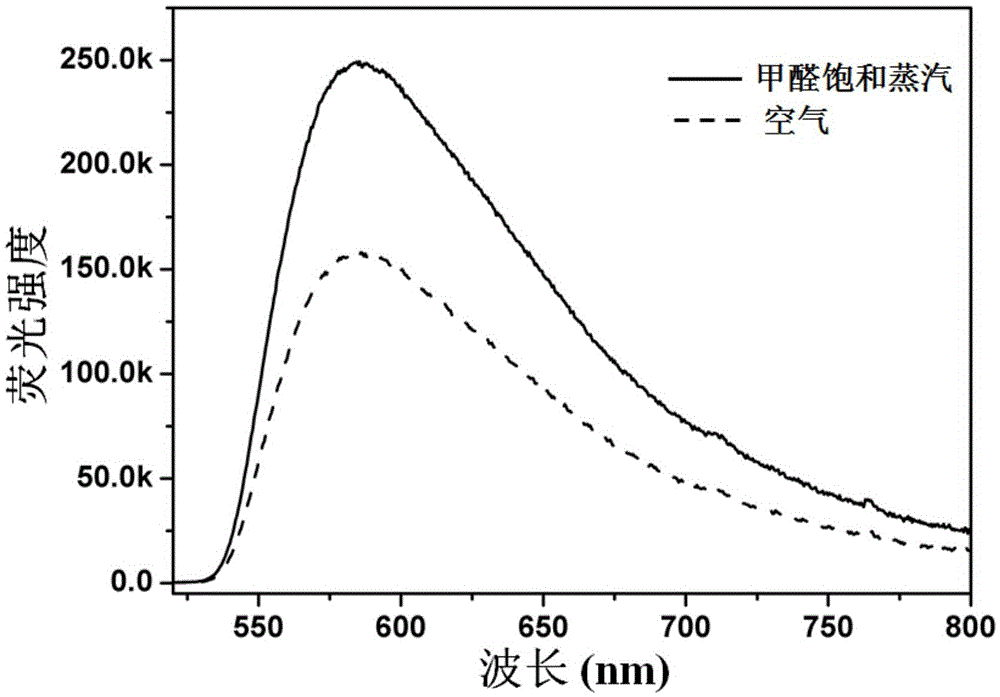

[0033] The application of the ionic liquid microarray monomolecular layer fluorescent sensing film containing the amphiphilic fluoroborate dipyrrole derivative prepared in Example 1 in the detection of formaldehyde gas is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com