Preparation method and application of organic-inorganic hybrid amino polymer adsorbent for adsorbing dye and heavy metal ions

A heavy metal ion, amino polymer technology, applied in the field of nano functional materials and water treatment, can solve the problems of small adsorption capacity of adsorbent, cumbersome process, small dye adsorption capacity, etc., and achieve outstanding adsorption effect, high adsorption capacity, and adsorption effect. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

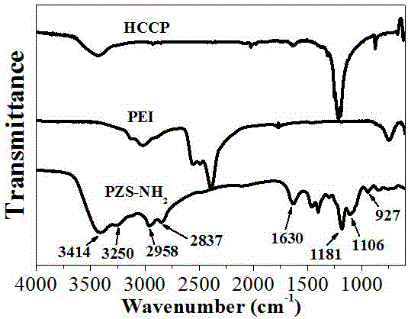

[0025] A preparation method for an organic-inorganic hybrid amino polymer adsorbent for adsorption of dyes and heavy metal ions, comprising the following steps:

[0026] ① In a 50 ml beaker, ultrasonically disperse 0.2 g of hexachlorocyclotriphosphazene into 20 ml of acetonitrile to make a hexachlorocyclotriphosphazene solution;

[0027] ②In a 250ml single-necked round bottom flask, ultrasonically disperse 0.345g of polyethyleneimine into 80ml of acetonitrile to make polyethyleneimine solution;

[0028] ③Add the hexachlorocyclotriphosphazene solution in the beaker to the polyethyleneimine solution, and mix evenly to obtain a mixed solution;

[0029] ④ Add 3 g of triethylamine dropwise to the mixed solution, react in ultrasonic at 25°C (ultrasonic power is 100 watts, ultrasonic frequency is 40 kHz) for 2 hours, centrifuge, wash with acetone, and then wash with deionized water , vacuum drying at 60° C. for 24 hours to obtain the organic-inorganic hybrid amino polymer adsorbent....

Embodiment 2

[0033] A preparation method for an organic-inorganic hybrid amino polymer adsorbent for adsorption of dyes and heavy metal ions, comprising the following steps:

[0034] ① In a 50 ml beaker, ultrasonically disperse 0.1 g of hexachlorocyclotriphosphazene into 20 ml of acetonitrile to make a hexachlorocyclotriphosphazene solution;

[0035] ②In a 250ml single-necked round bottom flask, ultrasonically disperse 0.15g of polyethyleneimine into 80ml of acetonitrile to make polyethyleneimine solution;

[0036] ③Add the hexachlorocyclotriphosphazene solution in the beaker to the polyethyleneimine solution, and mix evenly to obtain a mixed solution;

[0037] ④ The mixed solution was ultrasonically reacted at 20°C (ultrasonic power is 100 watts, ultrasonic frequency is 40 kHz) for 5 hours, centrifuged, washed with acetone and deionized water, and vacuum dried at 80°C for 20 hours to obtain The organic-inorganic hybrid amino polymer adsorbent.

Embodiment 3

[0039] A preparation method for an organic-inorganic hybrid amino polymer adsorbent for adsorption of dyes and heavy metal ions, comprising the following steps:

[0040] ① In a 50 ml beaker, ultrasonically disperse 0.4 g of hexachlorocyclotriphosphazene into 20 ml of acetonitrile to make a hexachlorocyclotriphosphazene solution;

[0041] ②In a 250ml single-necked round bottom flask, ultrasonically disperse 1.38g of polyethyleneimine into 80ml of acetonitrile to make polyethyleneimine solution;

[0042] ③Add the hexachlorocyclotriphosphazene solution in the beaker to the polyethyleneimine solution, and mix evenly to obtain a mixed solution;

[0043] ④ Add 1 gram of sodium hydroxide dropwise to the mixed solution, react in ultrasonic at 50°C (ultrasonic power is 100 watts, ultrasonic frequency is 40 kHz) for 1 hour, centrifuge, wash with acetone, and then wash with deionized water , vacuum drying at 30° C. for 22 hours to obtain the organic-inorganic hybrid amino polymer adsorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com