Intelligent response liquid chromatogram filling material and preparation method thereof

A liquid chromatography, intelligent technology, applied in the field of intelligent response liquid chromatography packing and its preparation, to achieve the effect of good physical and chemical stability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

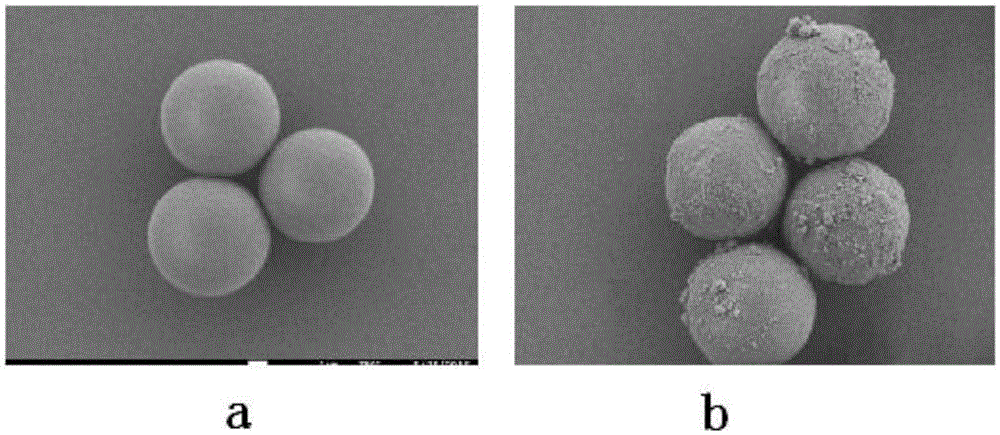

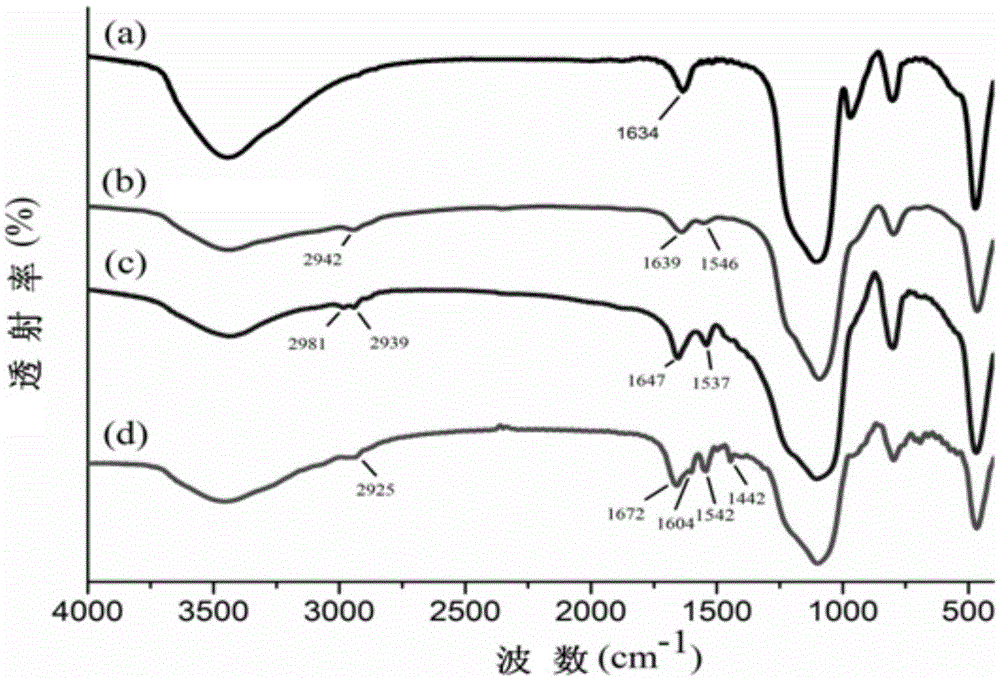

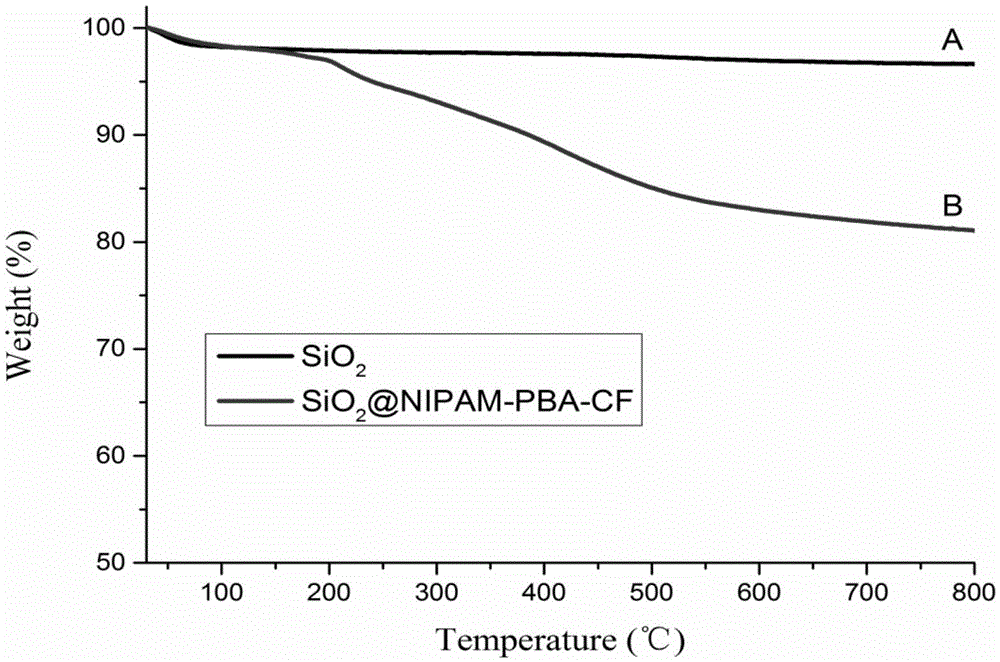

Image

Examples

Embodiment 1

[0036] The specific steps of compounding intelligent response materials on the surface of silicon spheres are as follows:

[0037] (1) Weigh the particle size of 2 ~ 5μm, the pore size is 2g of silicon spheres, mixed with 120mL, 1mol / L HCl ultrasonically, stirred and refluxed at 90°C for 3h, after the reaction, filtered, washed with pure water until neutral, and the washed silicon spheres were heated at 150°C Dry overnight;

[0038] (2) Weigh 1.2 g of the cleaned silicon spheres, suspend them with 50 mL of toluene, add 0.54 mL (3 mmol) of 3-aminopropyltrimethoxysilane (APTES) and react at 20-25 °C for 16 hours, centrifuge in toluene 3 times, suspend again with 50mL toluene, add 0.24mL (3mmol) pyridine, keep it at 0°C in the low temperature reactor, pipette 0.37mL (3mmol) of bromoisobutyryl bromide and dilute with 5mL toluene, under the protection of nitrogen Make it dropwise into the reaction bottle, react at 0°C for 2h, react at room temperature for 12h, wash with toluene,...

Embodiment 2

[0056] (1) The particle size is 6-10 μm and the pore size is 2g of silicon spheres, mixed with 120mL, 5mol / L HCl ultrasonically, stirred and refluxed at 100-110°C for 7h, after the reaction, filtered, washed with pure water until neutral, so that the washed silicon spheres Dry overnight at 150°C;

[0057] (2) Weigh 5 g of the cleaned silicon spheres, suspend them with 80 mL of toluene, add 0.64 mL (4 mmol) of 3-aminopropyltrimethoxysilane (APTES) and react at 90 ° C for 5 h, centrifuge 3 times in toluene, Ultrasonic suspend again with 50mL of toluene, add 0.32mL (4mmol) of pyridine, keep it at 0°C in the low-temperature reactor, pipette 0.37mL (3mmol) of bromoisobutyryl bromide and dilute with 5mL of toluene, and let it drop under the protection of nitrogen Add it into a reaction bottle, react at 0°C for 3 hours, and react at room temperature for 18 hours, wash with toluene, water, methanol, dichloromethane, acetone, and then vacuum dry at 150°C for 2 hours;

[0058] (3) So...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com