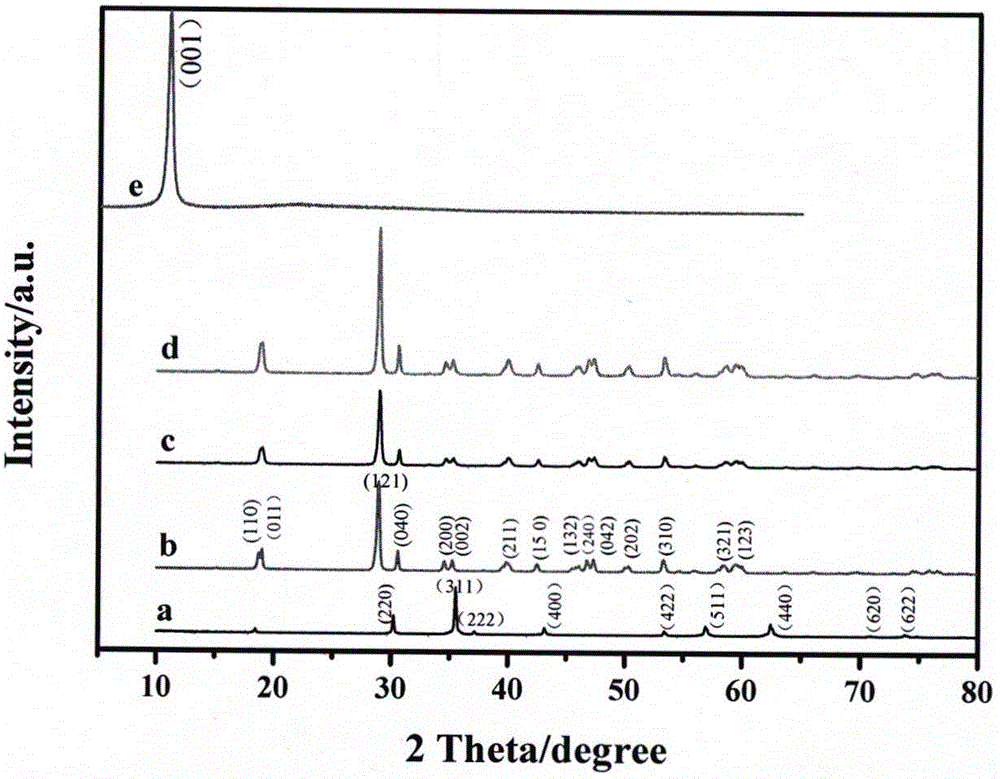

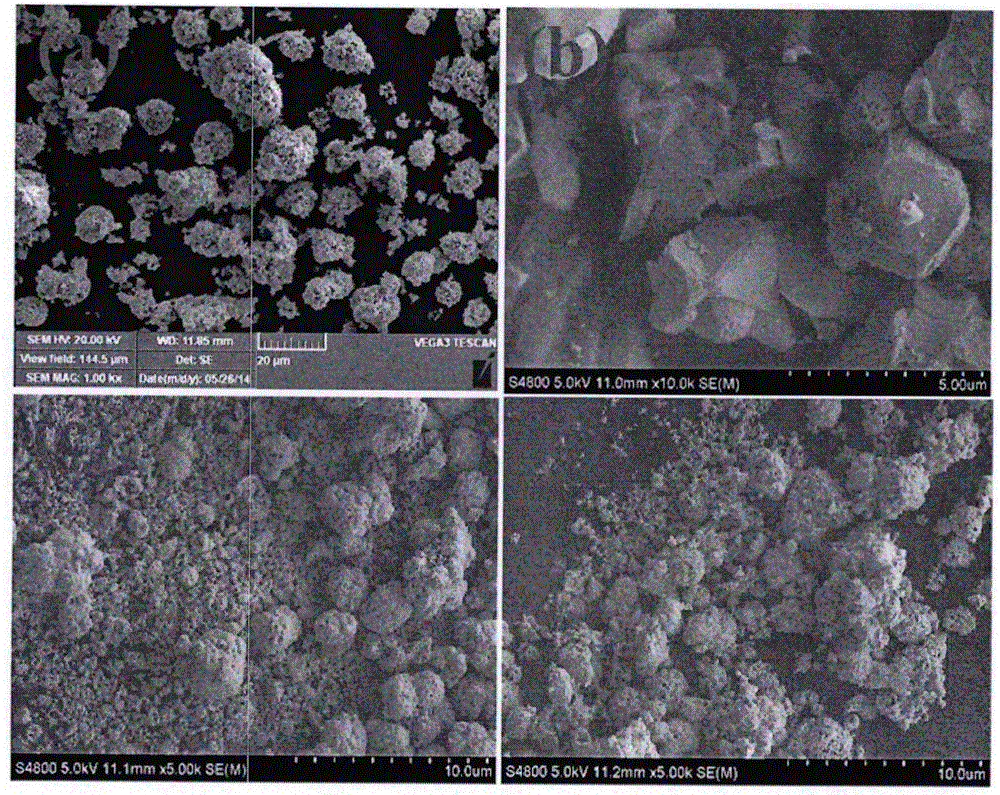

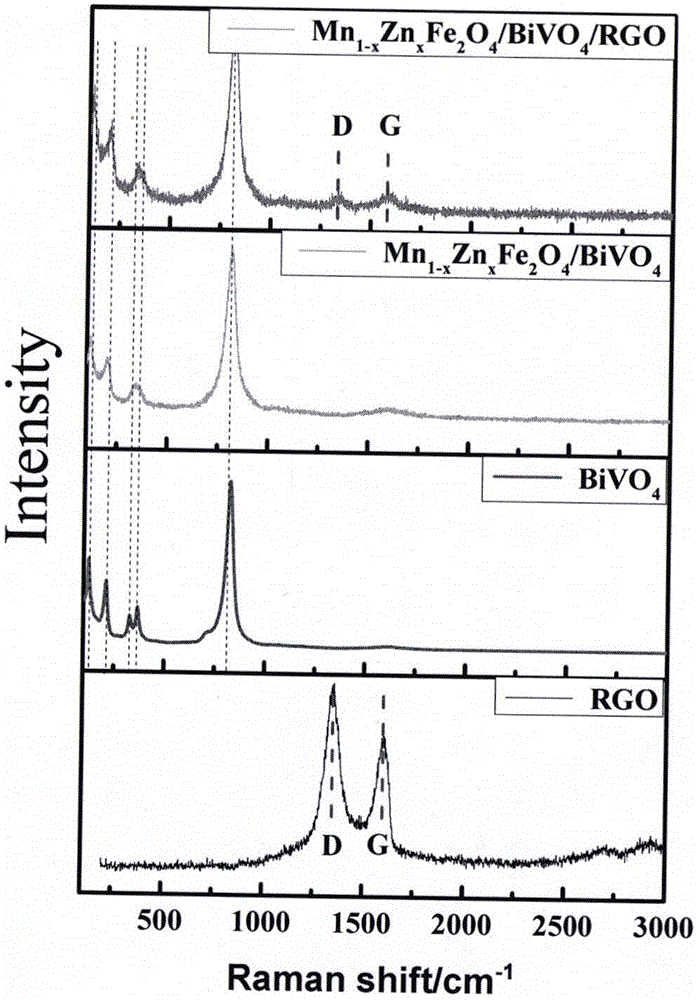

Graphene composite magnetic photocatalyst Mn1-xZnxFe2O4/BiVO4/RGO preparation method

A graphene composite and photocatalyst technology, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problems of low photocatalyst efficiency and low recovery rate, and achieve production costs Low, less equipment, inhibit the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A graphene composite magnetic photocatalyst Mn 1-x Zn x Fe 2 o 4 / BiVO 4 The preparation method of / RGO, concrete steps are as follows:

[0029] (1) BiVO 4 Preparation of precursor solution

[0030] Weigh 10mmol of analytically pure Bi(NO 3 ) 3 ·5H 2 O dissolved in 50 mL of HNO with a concentration of 2 mol / L 3 , ultrasonic oscillation, to obtain solution A; molar ratio Bi(NO 3 ) 3 ·5H 2 O:C 4 h 6 o 6 =10:3, weigh 3mmol of analytically pure C 4 h 6 o 6 (Tartaric acid) was dissolved in 50mL80°C hot water to obtain solution B; by molar ratio Bi(NO 3 ) 3 ·5H 2 O: NH 4 VO 3 =1:1, weigh 10mmol analytically pure NH 4 VO 3 Dissolve in 50mL of hot water at 80°C to obtain solution C; slowly add solution B to solution C, then add solution A to the mixed solution of B and C, cool to room temperature, adjust pH=7.5 with ammonia water, and obtain vanadic acid Bismuth (BiVO 4 ) precursor solution.

[0031] (2) Mn 1-x Zn x Fe 2 o 4 / BiVO 4 Preparation o...

Embodiment 2

[0036] A graphene composite magnetic photocatalyst Mn 1-x Zn x Fe 2 o 4 / BiVO 4 The preparation method of / RGO, concrete steps are as follows:

[0037] (1) with the step (1) of embodiment 1, wherein by molar ratio Bi(NO 3 ) 3 ·5H 2 O:C 4 h 6 o 6 =10:2, weigh 2mmolC 4 h 6 o 6 .

[0038] (2) With the step (2) of embodiment 1.

[0039] (3) with the step (3) of embodiment 1, wherein after making graphene oxide (GO) with potassium permanganate oxide graphite powder, by mass ratio Mn 1-x Zn x Fe 2 o 4 / BiVO 4 : GO=100:1, take the prepared 12mgGO and ultrasonically disperse it in 50ml deionized water to obtain a GO solution, add the above-prepared 1.2gMn 1-x Zn x Fe 2 o 4 / BiVO 4 ;Press NH 3 ·H 2 The volume (ml) of O: the mass (mg) of GO is 1:24, NH 3 ·H 2 O and N 2 h 4 ·H 2 The volume ratio of O is 1:1, add 0.5ml NH 3 ·H 2 O and 0.5mlN 2 h 4 ·H 2 O; react in a water bath at 80°C to reduce GO to graphene (RGO), filter, wash, and dry for 12 hours to ...

Embodiment 3

[0041] A graphene composite magnetic photocatalyst Mn 1-x Zn x Fe 2 o 4 / BiVO 4 The preparation method of / RGO, concrete steps are as follows:

[0042] (1) with the step (1) of embodiment 1, wherein by molar ratio Bi(NO 3 ) 3 ·5H 2 O:C 4 h 6 o 6 =10:4, weigh 4mmolC 4 h 6 o 6 .

[0043] (2) With the step (2) of embodiment 1.

[0044] (3) with the step (3) of embodiment 1, wherein after making graphene oxide (GO) with potassium permanganate oxide graphite powder, by mass ratio Mn 1-x Zn x Fe 2 o 4 / BiVO 4 : GO=100:5, take prepared 60mgGO and ultrasonically disperse in 50ml deionized water to obtain GO solution, add 1.2gMn 1-x Zn x Fe 2 o 4 / BiVO 4 ;Press NH 3 ·H 2 The volume (ml) of O: the mass (mg) of GO is 1:30, NH 3 ·H 2 O and N 2 h 4 ·H 2 The volume ratio of O is 1:3, add 2ml NH 3 ·H 2 O and 6mlN 2 h 4 ·H 2 O; react in a water bath at 80°C to reduce GO to graphene (RGO), filter, wash, and dry for 12 hours to prepare a graphene heterojunctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com