Method for preparing visible-light-active TiO2/Cu2S composite photocatalyst for removing Cr from water

A visible light and composite light technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high photogenerated electron/hole recombination probability, limited application, poor visible light activity, etc. Low cost, good photocatalytic activity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

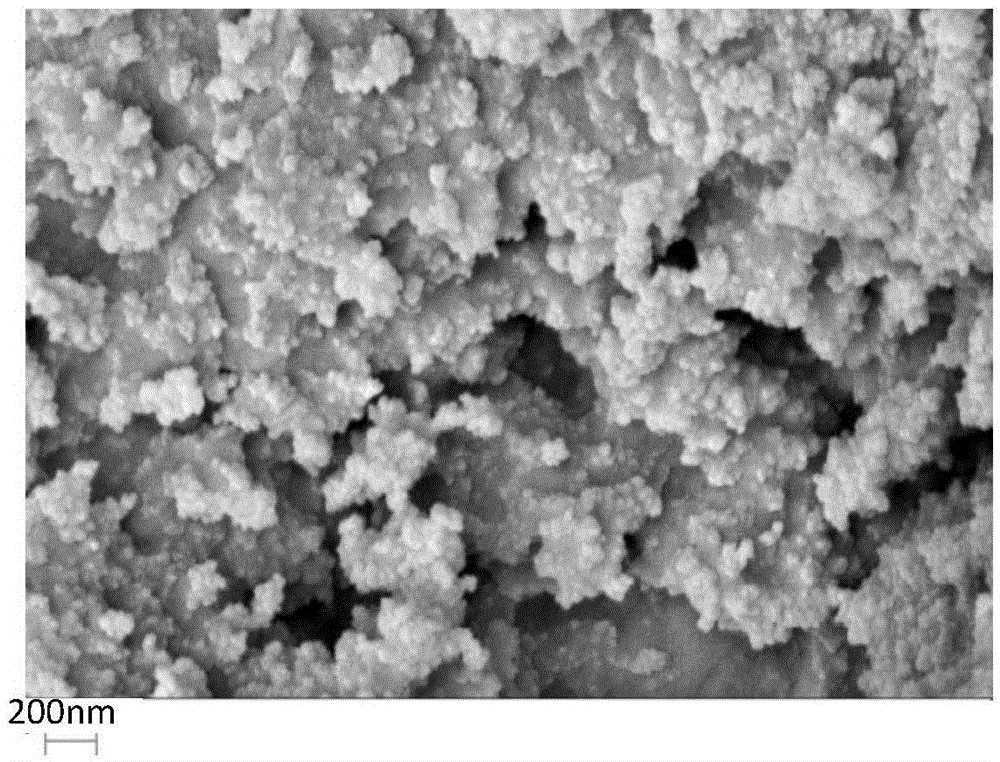

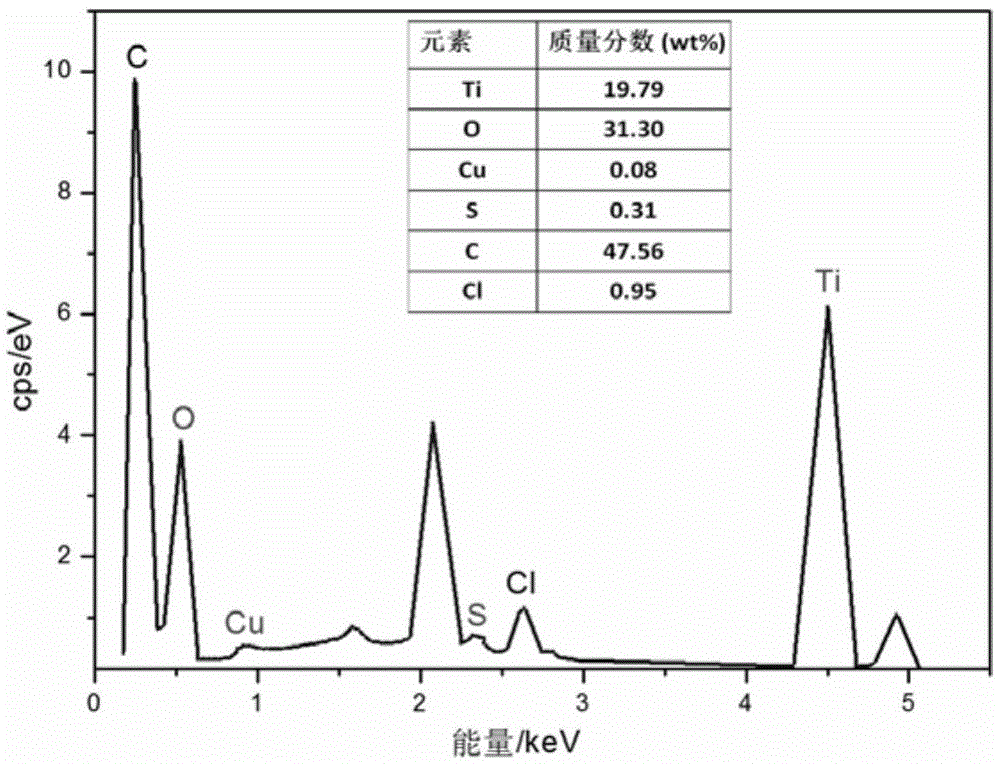

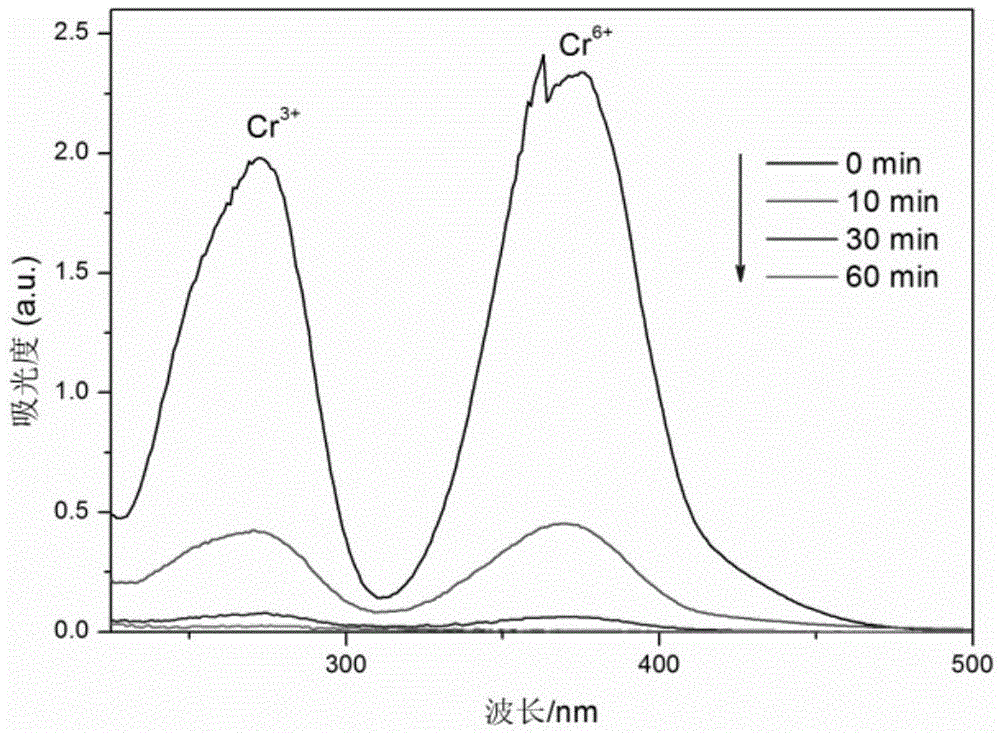

[0028] Prepare 20mL of titanium tetrachloride ethanol solution of 0.45mol / L in a 100mL beaker, 2 S:TiO 2 The molar ratio is 0.008:1, and the industrial grade Cu with a mass percentage of 80% is added to the beaker 2 S; place the beaker in an ultrasonic cleaner for ultrasonic treatment for 60 minutes. Then, gradually drop 4mL of hydrolyzing agent into the obtained dispersion liquid (the percentage of each component of hydrolyzing agent accounted for the mass of hydrolyzing agent is: sodium hexametaphosphate 0.4%, glycerol 0.2%, ethanol 1%, all the other components are water), continue to sonicate for 10 minutes to promote the titanium tetrachloride (TiCl 4 ), the obtained product was transferred to a 25mL polytetrafluoroethylene substrate hydrothermal reaction kettle, and placed in a blast drying oven at a temperature of 140°C for heat treatment for 3 hours, and then naturally cooled to room temperature after heat treatment. Finally, the hydrothermal product is washed with d...

Embodiment 2

[0030] Prepare 20mL of 0.4mol / L titanium tetrachloride ethanol solution in a 100mL beaker, according to the 2 S:TiO 2 The molar ratio is 0.02:1, and the industrial grade Cu with a mass percentage of 80% is added to the beaker 2 S; place the beaker in an ultrasonic cleaner for ultrasonic treatment for 60 minutes. Then, gradually drop 4mL of hydrolyzing agent into the obtained dispersion liquid (the percentage of each component of hydrolyzing agent accounted for the mass of hydrolyzing agent is: sodium hexametaphosphate 0.4%, glycerol 0.2%, ethanol 1%, all the other components are water), continue to sonicate for 10 minutes to promote the titanium tetrachloride (TiCl 4 ), the resulting product was transferred to a 25mL polytetrafluoroethylene substrate hydrothermal reaction kettle, and placed in a blast drying oven at a temperature of 180°C for 3 hours. After the heat treatment, it was naturally cooled to room temperature. Finally, the hydrothermal product was washed with dei...

Embodiment 3

[0032] Prepare 20mL of 0.4mol / L titanium tetrachloride ethanol solution in a 100mL beaker, according to the 2 S:TiO 2 The molar ratio is 0.02:1, and the industrial grade Cu with a mass percentage of 80% is added to the beaker 2 S; place the beaker in an ultrasonic cleaner for ultrasonic treatment for 60 minutes. Then, gradually add 4mL of hydrolyzing agent dropwise in the obtained dispersion liquid (the percentage of each component of hydrolyzing agent accounting for the mass of hydrolyzing agent is: sodium hexametaphosphate 0.4%, glycerol 0.2%, ethanol 1%, all the other components are water), continue to sonicate for 10 minutes to promote the titanium tetrachloride (TiCl 4 ), the obtained product was transferred to a 25mL polytetrafluoroethylene substrate hydrothermal reaction kettle, and placed in a blast drying oven at a temperature of 140°C for 3 hours. After the heat treatment, it was naturally cooled to room temperature. Finally, the hydrothermal product was washed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com