Ionic-like liquid and preparation method and application thereof in preparation of alkylated oil

A technology for ionic liquids and alkylated oils, applied in catalytic reactions, chemical instruments and methods, organic chemistry, etc., can solve the problem that the octane number of alkylated oils needs to be further improved, the requirements for synthetic raw materials are high, and the synthetic methods are complicated etc. to achieve the effect of strong water resistance, low cost and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

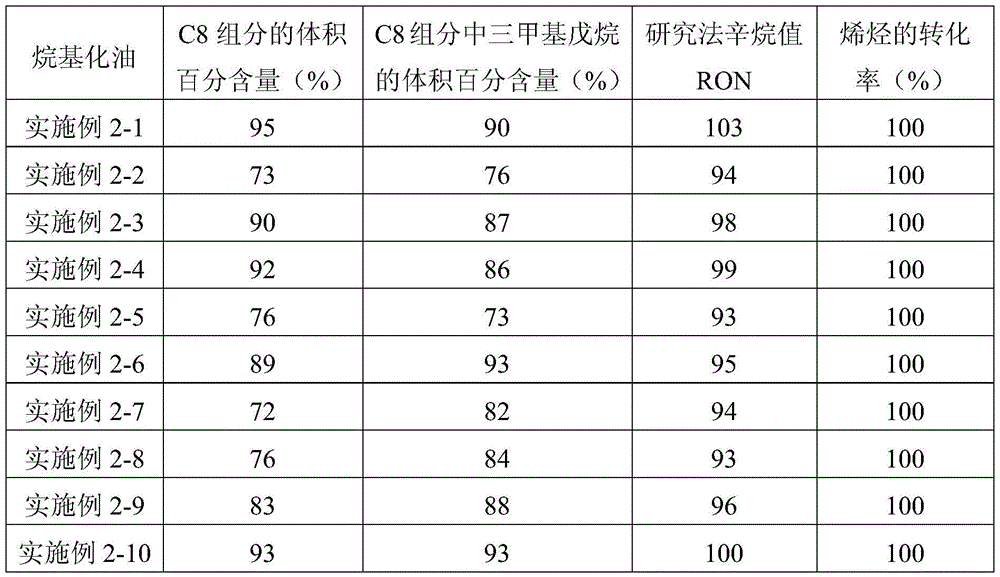

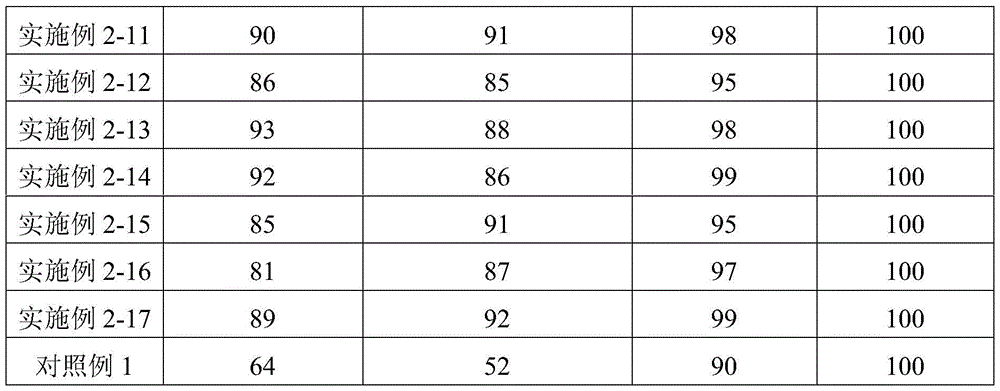

Examples

Embodiment 1

[0036] The preparation of a class of ionic liquids

Embodiment 1-1

[0038] Slowly add 0.065 mol (3.84 g) of acetamide to 0.1 mol (13.34 g) of AlCl 3 , using n-heptane as a solvent, under nitrogen protection, stirring at room temperature for 30 minutes, then heating to 80° C., and continuing to stir for 2 hours to complete the reaction to obtain a reaction mixture. Subsequently, the reaction mixture is cooled, and after cooling, it is divided into two phases, wherein the upper strata is n-heptane, and the lower floor is the reactant. After separating the upper strata n-heptane, 0.015 moles (1.48 grams) of CuCl are added to the reactant under nitrogen protection and The temperature was raised to 120° C., and stirring was continued for 2 hours to completely react CuCl to obtain an ionic liquid.

Embodiment 1-2

[0040] In dry air, without n-heptane as a solvent, 0.015 moles (2.02 g) of CuCl 2 and 0.1 mol (13.34 g) of AlCl 3 Mix evenly to obtain a metal mixture; subsequently, slowly add 0.065 moles (3.84 grams) of acetamide into the above metal mixture, stir and mix at room temperature and then raise the temperature to 120°C for reaction, the reaction process exotherms and forms a tan liquid. The reaction temperature was controlled at 120° C., and the stirring was continued for 4 hours to complete the reaction to obtain an ionic liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com