Oxidation film removing method based on femtosecond laser etching

A technology of oxide film removal and femtosecond laser, which is applied in the field of light metal welding, can solve problems such as environmental pollution, incomplete cleaning, and scratches on the substrate surface, so as to avoid environmental pollution problems, accurately control the cleaning area, and reduce the formation of pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

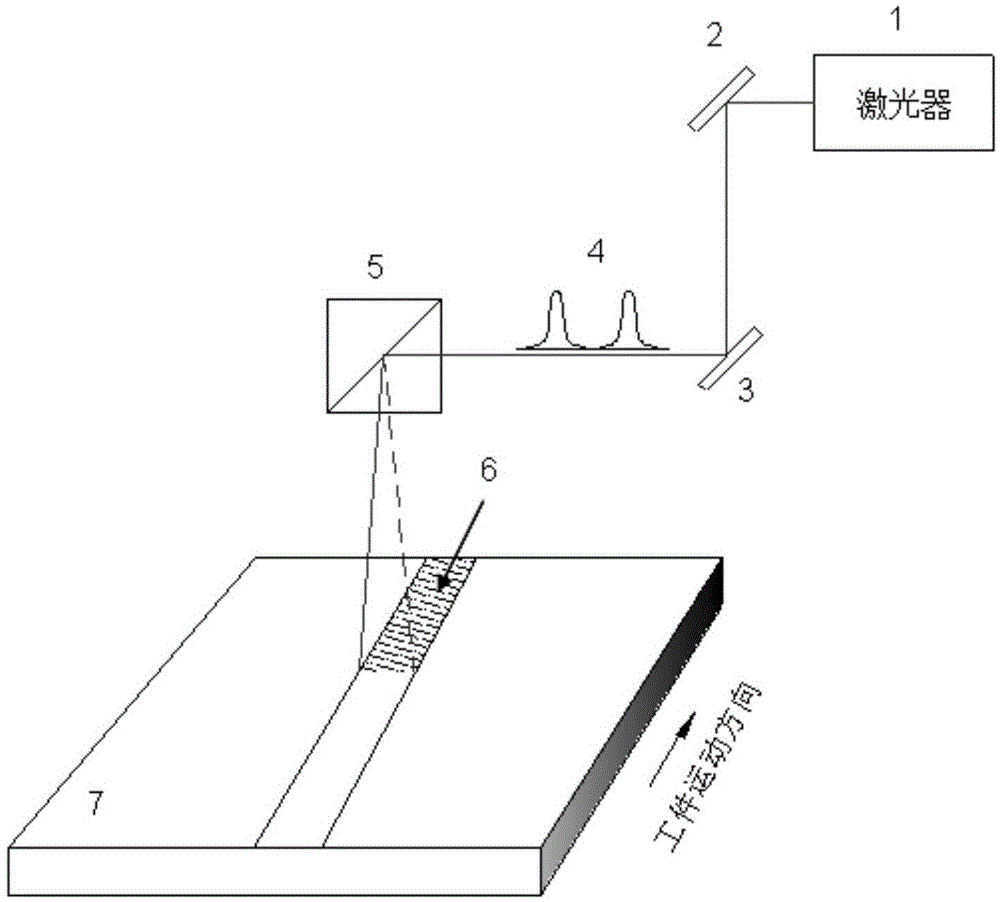

[0024] The schematic diagram of the technical solution of this embodiment is as attached figure 1 shown. After the femtosecond laser pulse 4 is output from the femtosecond laser 1, it is transmitted through the transmission mirror a and the transmission mirror b and enters the scanning galvanometer 5, and the scanning galvanometer 5 controls the femtosecond pulse sequence 4 to scan the surface of the workpiece 7 horizontally line by line. The longitudinal linear movement of the workpiece realizes the clean removal of the oxide film in the oxide film removal zone 6 .

[0025] The scanning mode of the laser beam is horizontal or vertical progressive scanning, or multiple scans in which horizontal sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com