Method for producing sodium metasilicate pentahydrate

A technology of sodium metasilicate pentahydrate and its production method, which is applied in the direction of silicate, alkali metal silicate, etc., can solve the problems of difficult removal of impurities, small application scale and scope, and difficult control, etc., and achieve large-scale Large-scale application, reduced energy consumption, and easy control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

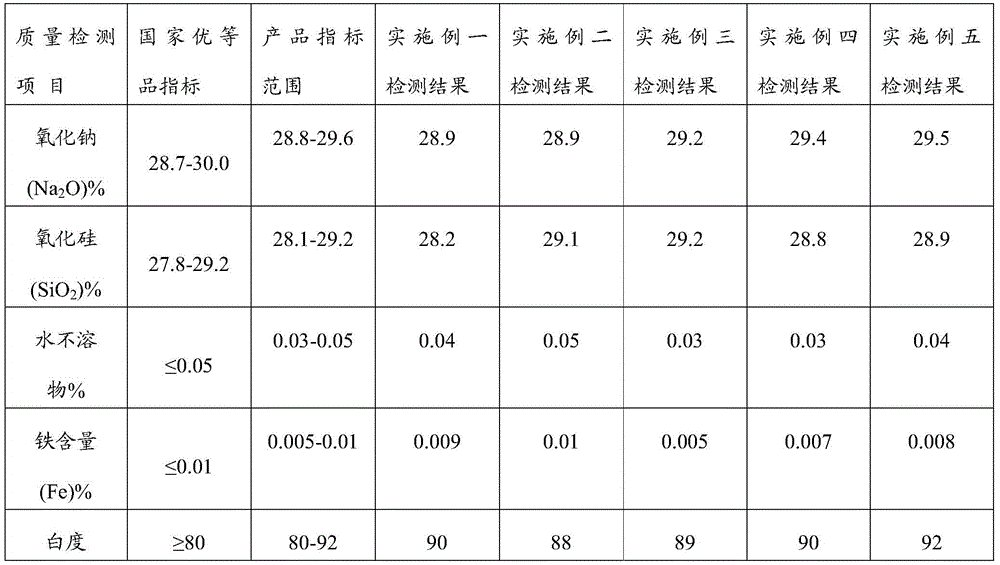

Examples

Embodiment 1

[0033] The production method of sodium metasilicate pentahydrate of the present embodiment, its concrete steps are:

[0034] 1. Purification: Purify the micro-silicon powder with a purity of 96% collected from the production of fused zirconia, and use rapid sedimentation separation, dilute acid leaching, cleaning and other processes to remove the pipe iron filings and ZrO contained in the micro-silicon powder 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO and other impurities, the main component SiO 2 content increased to more than 99%;

[0035] 2. Mixing: Add sodium hydroxide into the microsilica powder slurry, make the lye concentration of 38% according to the proportion, stir and mix;

[0036] 3. Reaction: Heat the reactor to 60°C for 60 minutes;

[0037] 4. Filtration: filter the reacted material with a filter press, and return the filter residue to the reactor to continue the reaction;

[0038] 5. Modulus adjustment: adjust the filtered clear liquid, and the adjusted modulus of t...

Embodiment 2

[0042] The production method of sodium metasilicate pentahydrate of the present embodiment, its concrete steps are:

[0043] 1. Purification: Purify the micro-silicon powder with a purity of 90% collected from the production of fused zirconia, and use rapid sedimentation separation, dilute acid leaching, cleaning and other processes to remove the pipe iron filings and ZrO contained in the micro-silicon powder 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO and other impurities, the main component SiO 2 content increased to more than 99%;

[0044] 2. Mixing: Add sodium hydroxide into the microsilica powder slurry, make the lye concentration of 38% according to the proportion, stir and mix;

[0045] 3. Reaction: Heat the reactor to 80°C for 30 minutes;

[0046] 4. Filtration: filter the reacted material with a filter press, and return the filter residue to the reactor to continue the reaction;

[0047] 5. Modulus adjustment: adjust the filtered clear liquid, and the adjusted modulus of...

Embodiment 3

[0051] In the production method of sodium metasilicate pentahydrate in this embodiment, solid sodium hydroxide, microsilica powder and water are mixed to obtain a mixed solution with a sodium hydroxide mass concentration of 37%, and the mixed solution is placed at 60°C React for 30 minutes, then filter the reacted mixed solution, add the filtered filter residue into the mixed solution to continue to participate in the reaction, take the filtered clear liquid to adjust the mold, adjust the modulus to 0.6, and adjust the mold The supernatant liquid was crystallized by adding seeds at 40° C. to obtain the sodium metasilicate pentahydrate. The obtained sodium metasilicate pentahydrate was concentrated to a solid content of 56%, followed by solid-liquid separation and drying in sequence, and the drying temperature was 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com