Three-section type biogas reactor

A three-stage, reactor technology, used in chemical instruments and methods, water/sludge/sewage treatment, waste fuels, etc. problems, to achieve the effect of improving the granulation rate of methane bacteria, low power consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

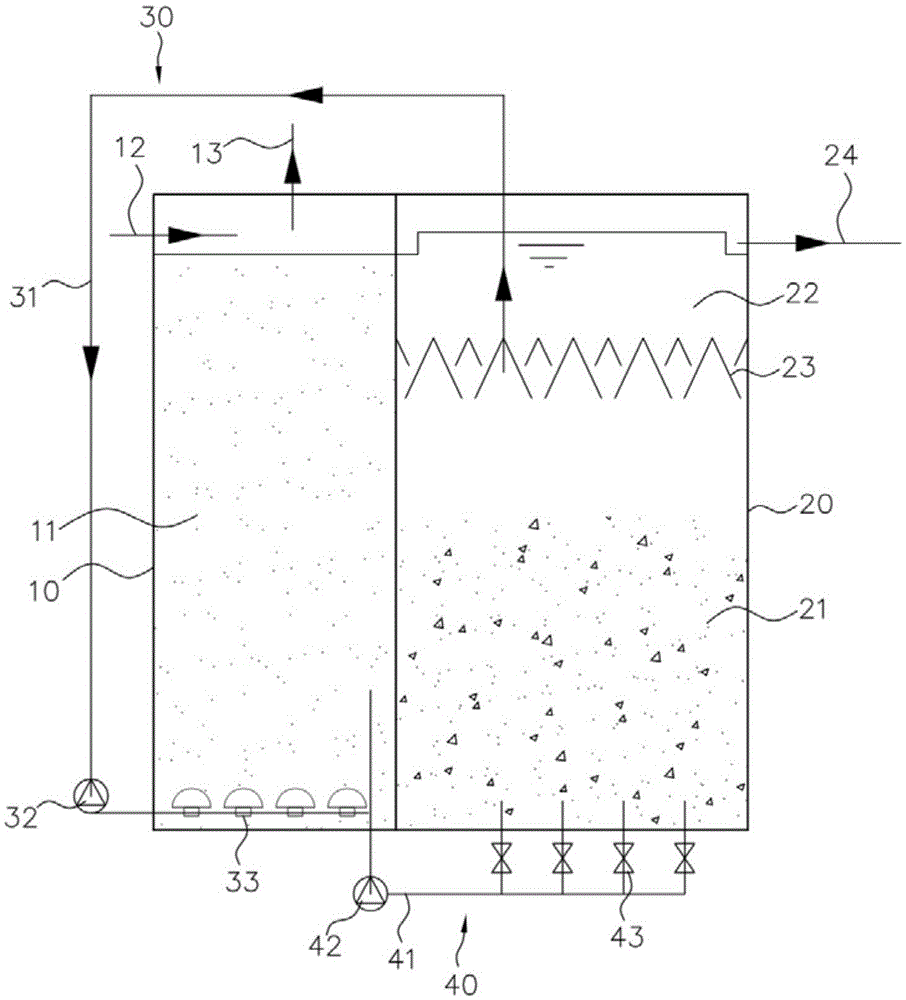

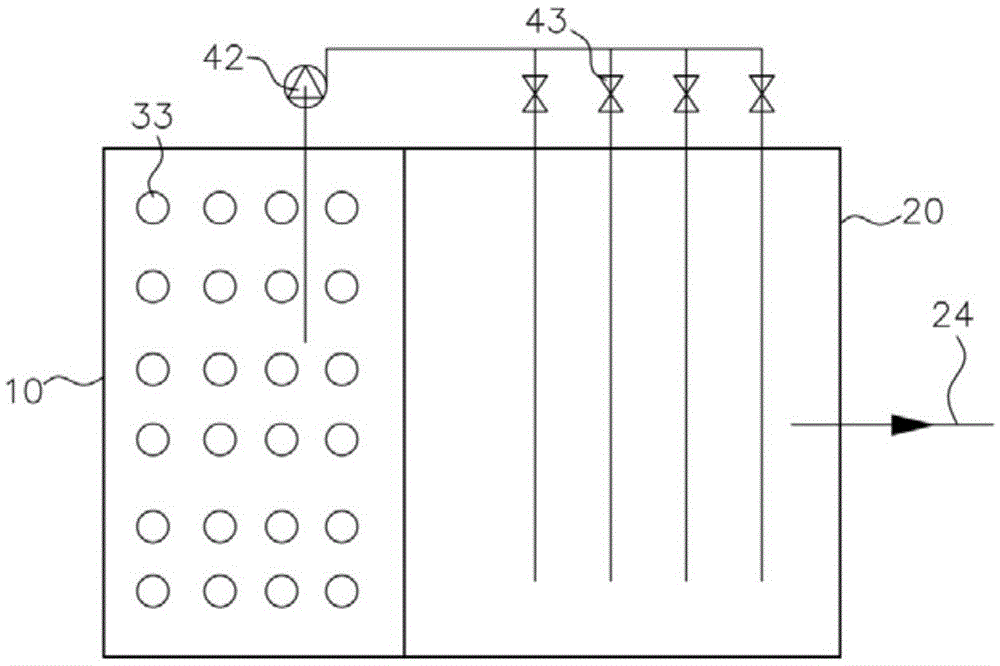

[0024] combine figure 1 , figure 2 , a three-stage biogas reactor comprising a first chamber 10 and a second chamber 20, the first chamber is provided with a pre-anaerobic zone 11, and the second chamber is provided with a main anaerobic zone 21 and methane Bacteria separation area 22, sludge is provided in the main anaerobic area, and the methane bacteria isolation area is located above the main anaerobic area.

[0025] A three-phase separator 23 is provided between the main anaerobic zone and the methane bacteria separation zone. The methanogen separation zone is communicated with the pre-anaerobic zone through the ventilation pipeline 30, and the pre-anaerobic zone is connected with the pre-anaerobic zone through the water pipeline 40. The main anaerobic zone is communicated; the first chamber is provided with a water inlet 12 communicated with the pre-anaerobic zone and a biogas outlet 13 after separation, and the second chamber is provided with a water outlet 24 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com