Silicon-containing wastewater treatment method, silicon-containing wastewater utilization system, molecular sieve preparation method and molecular sieve preparation system

A treatment method, molecular sieve technology, applied in ceramic wastewater treatment, molecular sieve and alkali exchange compound, natural water treatment, etc., can solve the problems such as adverse effects of molecular sieve quality, achieve high silicon recovery rate, high waste water utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The silicon-containing wastewater comes from the preparation process of molecular sieves, and the molecular sieves can be various common silicon-containing molecular sieves, such as Y-type molecular sieves, X-type molecular sieves, A-type molecular sieves, MCM-type molecular sieves, ZSM-type molecular sieves (such as ZHP molecular sieves) ), mordenite-type molecular sieves, β-type molecular sieves and titanium-silicon molecular sieves.

[0066] The silicon-containing waste water can be the crystallization mother liquor in the molecular sieve preparation process, the washing waste water produced in the washing step, and the ion exchange waste liquid produced in the ion exchange process. The method of the present invention is particularly suitable for treating silicon-containing waste liquids with higher silicon content, for example, silicon-containing waste liquids with a silicon element content of more than 10 mg / L (such as 10-15000 mg / L), preferably more than 50 mg / L F...

Embodiment 1

[0149] The silicon-containing wastewater treated in this example is the first stage of washing wastewater generated during the preparation of hydrogen-type ZHP molecular sieves, and the types and contents of the elements contained therein are listed in Table 1.

[0150] The bipolar membrane used in this embodiment is commercially available from Aston Corporation, Japan, and the model is BP-1; the cation exchange membrane is a styrene-type homogeneous cation exchange membrane (the ion exchange capacity is 2.51meq / g dry film, film surface resistance (25°C, 0.1mol / L NaCl aqueous solution, the same below) is 4.59Ω·cm 2 ); anion-exchange membrane commercially purchased from the styrene-type homogeneous anion-exchange membrane of Hebei Guangya Company (the ion exchange capacity is 2.45meq / g dry film, and the membrane surface resistance is 9.46Ω·cm 2 ).

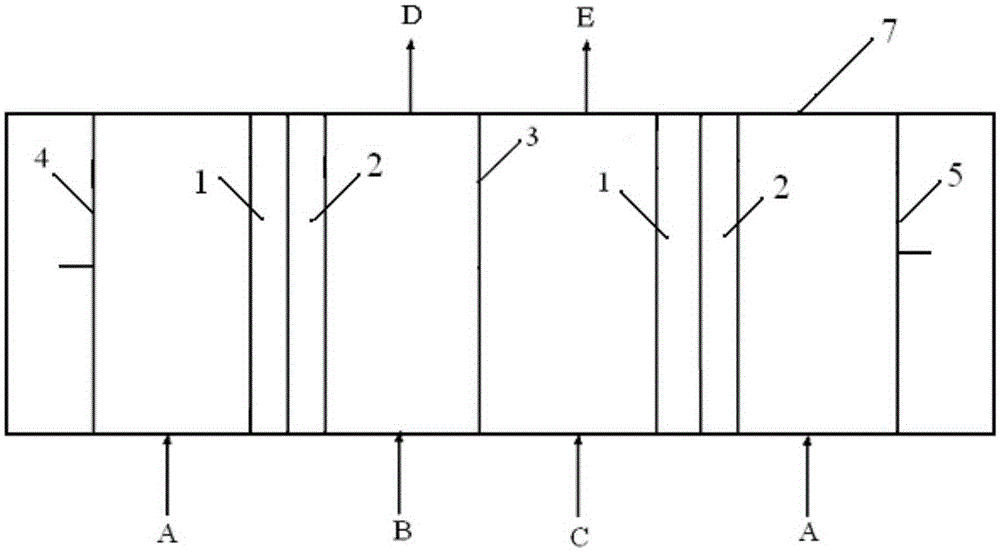

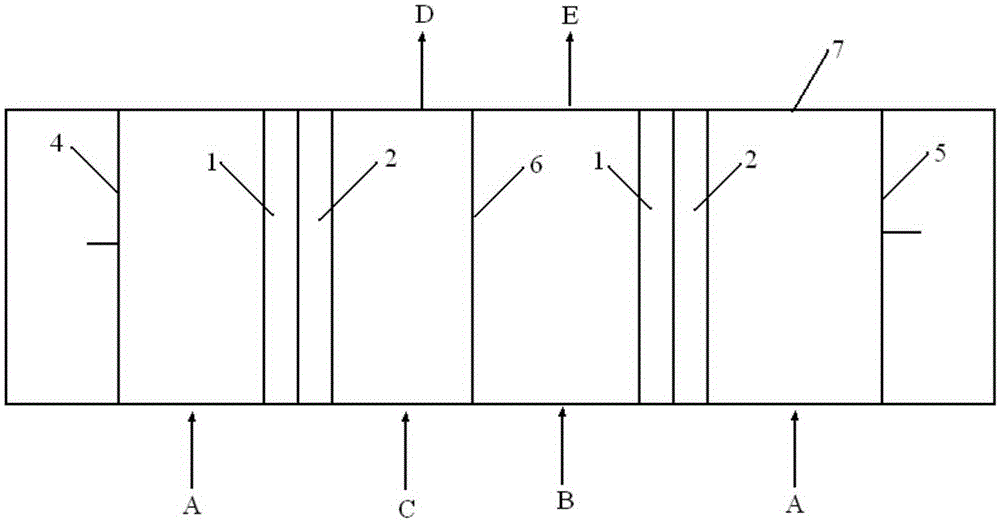

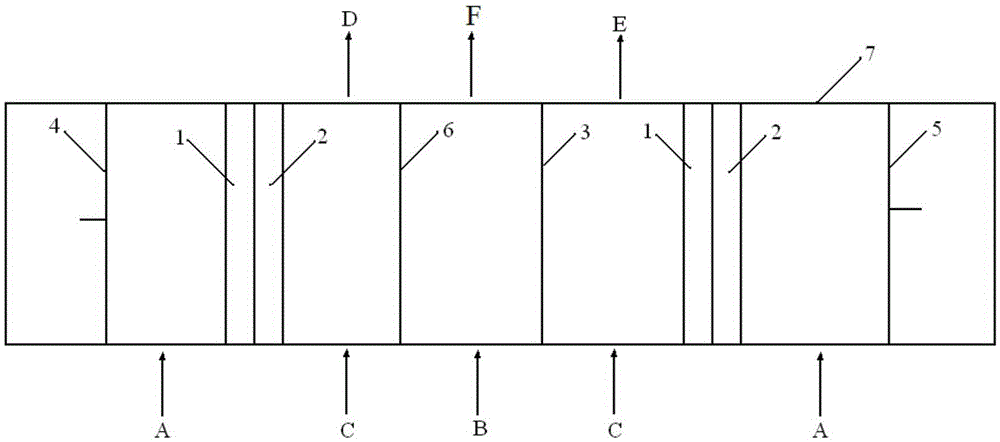

[0151] In this embodiment, the following technological process is adopted to treat silicon-containing wastewater.

[0152] (1) ...

Embodiment 2

[0161] Silicon-containing wastewater is treated in the same manner as in Example 1. The difference is that in step (1), sulfuric acid (mass concentration is 3.5%) is added to silicon-containing wastewater to adjust the pH value of silicon-containing wastewater to 4.8, then stirred and reacted at room temperature (25°C, the same below) for 5 hours to obtain a mixture containing colloidal silica. The content of silicon dioxide in the filter residue obtained in step (2) is 96% by weight, which can be used as a silicon source in the molecular sieve synthesis process. The experimental results are listed in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com