High-efficiency nitrogen and carbon removal treatment process for aquaculture wastewater with low c/n ratio anaerobic biogas slurry

A technology for aquaculture wastewater and carbon treatment, which is applied in water/sewage treatment, biological water/sewage treatment, multi-stage water/sewage treatment, etc., can solve problems such as energy consumption loss, achieve small footprint, good effluent quality, Less impact load resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

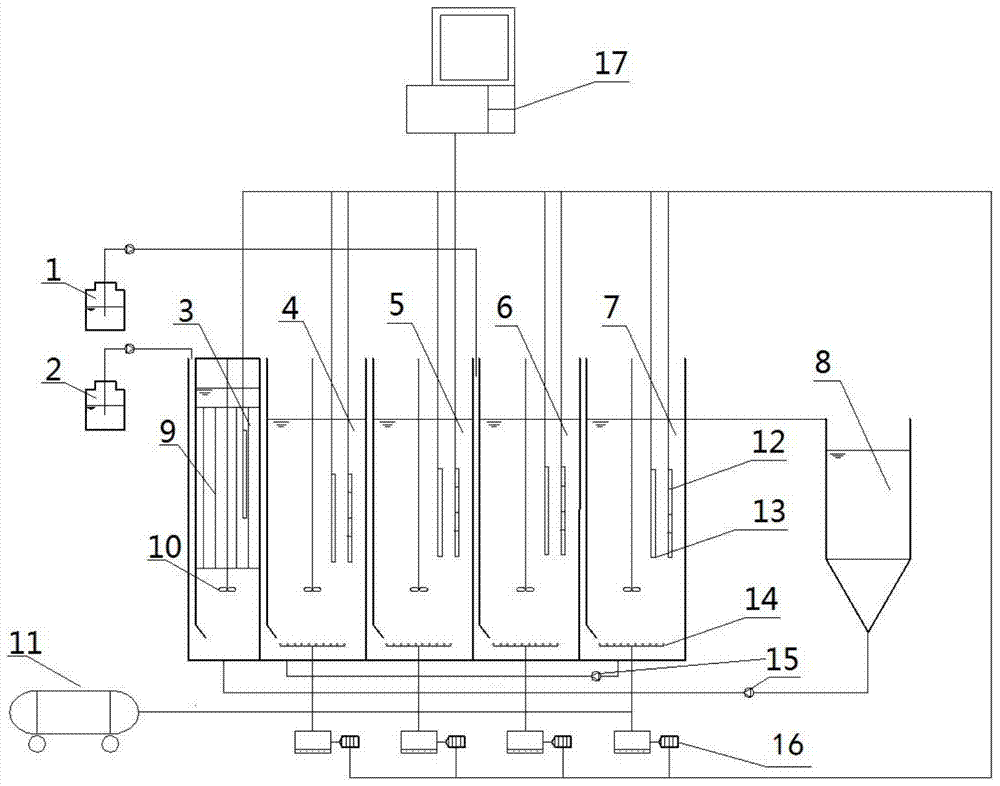

Method used

Image

Examples

Embodiment

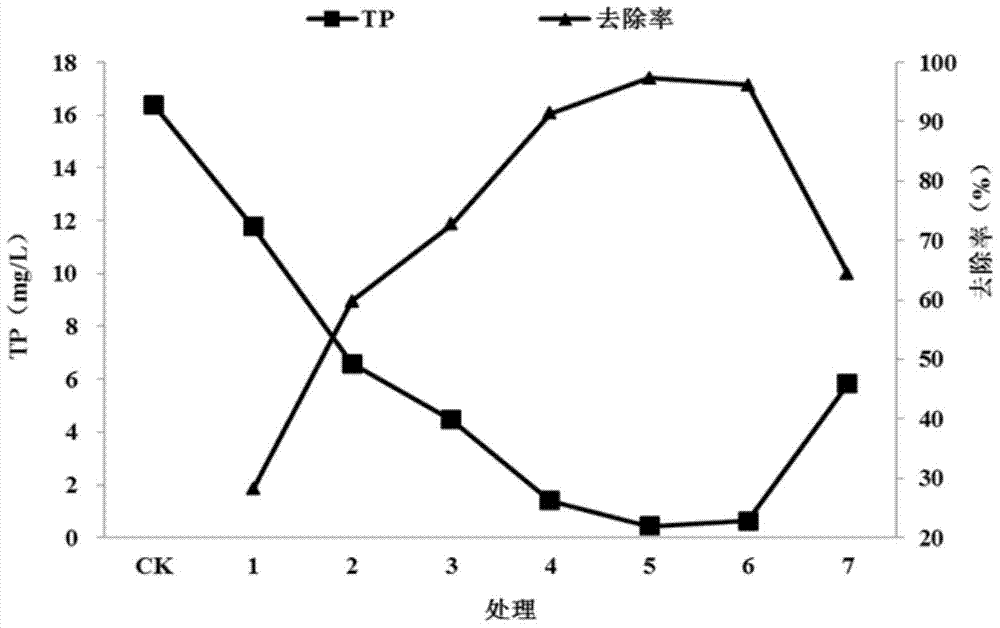

[0039] Taking the wastewater treatment process of a large-scale breeding pig farm as an example, the above-mentioned device is used to treat the pig farm wastewater. The water quality of raw water and anaerobic biogas slurry is shown in Table 1:

[0040] Table 1 Wastewater quality of a large-scale breeding pig farm

[0041] Unit: mg / L (except pH value)

[0042]

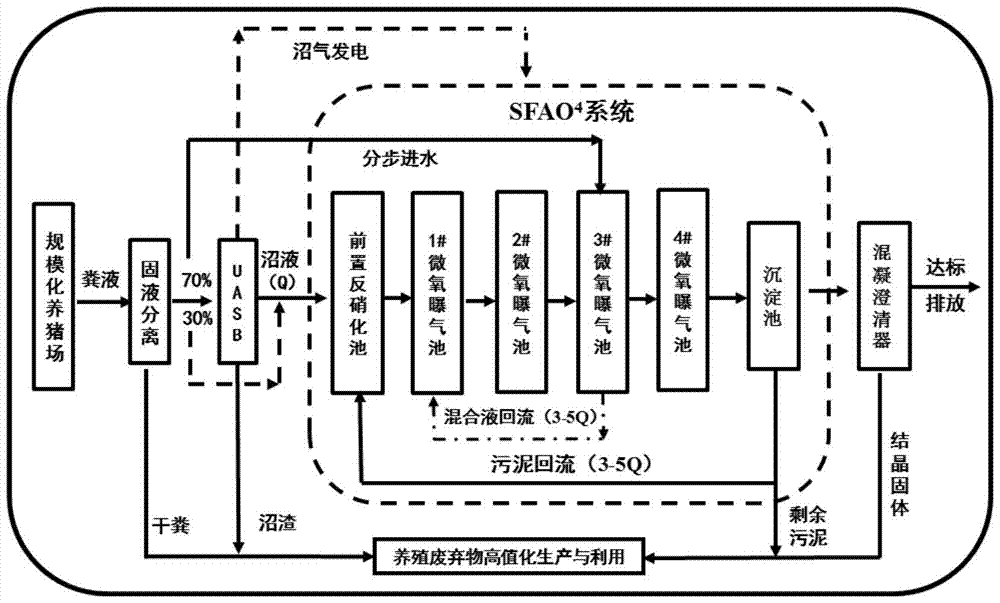

[0043] The specific process of the invention method is as follows: figure 2 , 150 tons of pig farm waste water is separated from solid and liquid through a slag remover, and the separated waste water is pumped into the UASB reactor for anaerobic fermentation reaction. The biogas generated during the anaerobic fermentation process is collected and purified for power generation. The generated electrical energy powers the devices in the system. After 15 days of reaction in the UASB reactor, the COD concentration can be reduced to about 2500mg / L. After the anaerobic reaction, the anaerobic biogas slurry and raw wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com