An environmentally friendly foamed ceramic insulation board prepared by electrolytic manganese slag and its preparation method

A technology for foaming ceramics and electrolytic manganese slag, which is applied in the production and application of ceramic products and ceramic materials, can solve the problems of foaming ceramics with no electrolytic manganese slag, tailings, waste slag, etc., and achieves high utilization rate and increased added value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

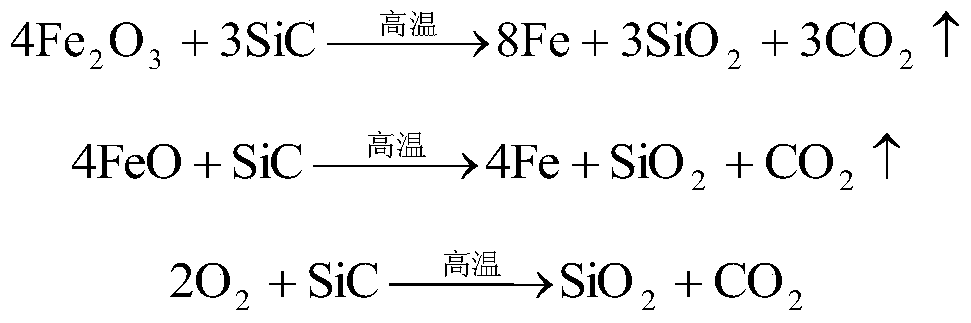

Method used

Image

Examples

Embodiment 1

[0030] Add 30wt% electrolytic manganese slag, 35wt% potassium albite feldspar, 25% kaolin, 10% talcum powder, plus 0.05% activated carbon powder, 0.5% green silicon carbide micropowder, add water ball mill, ball: material : Water (mass ratio) was 2:1:1, ball milled for 15min, and the rotating speed was 500rpm. The ground pulp is transferred to the drying equipment, dried at 101°C for 5 hours, then heated to 150°C for 2 hours, and the obtained dry powder is rolled and pressed and directly filled into a refractory sagger mold of a fixed size and then calcined in a kiln. The inner wall of the sagger is paved with refractory fiber paper in advance to prevent the high-temperature melt from sticking to the mold. The refractoriness of the refractory fiber paper is above 1200°C and the thickness is about 1mm. The mold enters the kiln, starts from 25°C at a heating rate of 15°C / min to 1000°C, and keeps at 1000°C for 50 minutes, at a heating rate of 5°C / min to 1200°C, and at 1200°C for ...

Embodiment 2

[0032] Add 45wt% of electrolytic manganese slag, 25wt% of potassium albite feldspar, 25% of kaolin, 5% of talc, plus 0.08% of coal powder and 1.0% of green silicon carbide micropowder into water ball mill, ball: material : Water (mass ratio) is about 2.5:1:1.5, ball milling for 50min, rotating speed 400rpm. The ground pulp is transferred to the drying equipment, dried at 105°C for 3 hours, then heated to 145°C for 3 hours, and the obtained dry powder is rolled and pressed and directly filled into a refractory sagger mold of a fixed size and then calcined in a kiln. The inner wall of the sagger is paved with refractory fiber paper in advance to prevent the high-temperature melt from sticking to the mold. The refractoriness of the refractory fiber paper is above 1200°C and the thickness is 2mm. The mold enters the kiln, starting from 200°C at a heating rate of 25°C / min to 1000°C, and holding at 1000°C for 80 minutes, at a heating rate of 8°C / min to 1200°C, and holding at 1200°C ...

Embodiment 3

[0034]Add water ball mill to the ingredients composed of 65wt% electrolytic manganese slag, 20wt% potassium albite feldspar, 10% kaolin, 5% talcum powder, 0.10% coke, 1.5% silicon nitride micropowder, ball: material: water (Mass ratio) is about 3:1:2, ball milling 120min, rotating speed 300rpm. The ground pulp is transferred to the drying equipment, dried at 110°C for 2 hours, then heated to 140°C for 5 hours, and the obtained dry powder is rolled and pressed and directly filled into a refractory sagger mold of a fixed size and then calcined in a kiln. The inner wall of the sagger is covered with refractory fiber paper in advance to prevent the high-temperature melt from sticking to the mold. The refractoriness of the refractory fiber paper is above 1200°C and the thickness is about 3mm. The mold enters the kiln, starts from 500°C at a heating rate of 35°C / min to 1000°C, and keeps at 1000°C for 100 minutes, at a heating rate of 10°C / min to 1200°C, and at 1200°C for 50 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com