A kind of pyrotechnic gas generating agent and preparation method thereof

A gas generating agent and pyrotechnic technology, which is applied in the production of compressed gas, attacking equipment, etc., can solve the problems of restricting the application of gas generating agent, reducing the density of energetic materials, and reducing detonation performance, so as to improve the safety of use, reduce the The effect of preparation cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

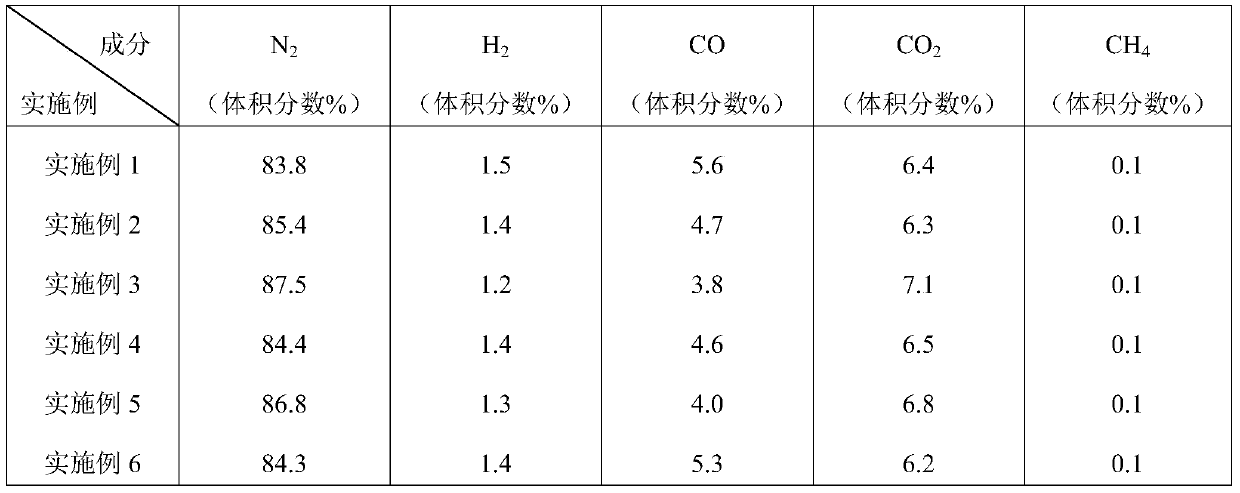

Embodiment 1

[0032] A pyrotechnic gas generating agent, based on the mass of the gas generating agent as 100%, its composition and mass fraction are: 4,5-bistetrazolyl-1,2,3-triazole (BTTZ)36 % (21.6g), LiNO 3 45% (27g), Fe 2 o 3 3% (1.8g), CuO 2% (1.2g), azotetrazolium diguanidine (GZT) 13% (7.8g) and phenolic resin 1% (0.6g);

[0033] A preparation method of pyrotechnic gas generating agent is as follows:

[0034] Step 1. Add LiNO 3Ball milled in a ball mill at 200r / min for 30min; put BTTZ in a quartz mortar and grind for 20min, and the ground LiNO 3 and BTTZ are placed in a desiccator for drying; the dried LiNO 3 and BTTZ were passed through a 100-mesh sieve, and the sieve was repeated 3 times to obtain LiNO with a particle size of ≤0.15mm 3 And BTTZ with particle size ≤0.15mm;

[0035] Step 2. LiNO with particle size ≤ 0.15mm 3 , BTTZ, Fe with particle size ≤0.15mm 2 o 3 , CuO and GZT are fully mixed, pass through a 50-mesh sieve, and repeat the sieve 4 times to obtain a unif...

Embodiment 2

[0037] A pyrotechnic gas generating agent, based on the mass of the gas generating agent as 100%, its composition and mass fraction are: 4,5-bistetrazolyl-1,2,3-triazole (BTTZ)32 % (19.2g), NaNO 3 57% (34.2g), Fe 2 o 3 2% (1.2g), CuO 1% (0.6g), Al(OH) 3 7% (4.2g) and phenolic resin 1% (0.6g);

[0038] A preparation method of pyrotechnic gas generating agent is as follows:

[0039] Step 1. Add NaNO 3 Ball milled in a ball mill at 200r / min for 40min; put BTTZ in a quartz mortar and grind for 20min, and the ground NaNO 3 and BTTZ is placed in a desiccator for drying; the dried NaNO 3 and BTTZ were passed through a 100-mesh sieve, and the sieve was repeated 4 times to obtain NaNO with a particle size of ≤0.15mm 3 And BTTZ with particle size ≤0.15mm;

[0040] Step 2. NaNO with particle size ≤ 0.15mm 3 , BTTZ, Fe with particle size ≤0.15mm 2 o 3 , CuO and Al(OH) 3 After fully mixing, pass through a 50-mesh sieve, and repeat the sieve 3 times to obtain a uniformly mixed p...

Embodiment 3

[0042] A pyrotechnic gas generating agent, based on the mass of the gas generating agent as 100%, its composition and mass fraction are: 4,5-bistetrazolyl-1,2,3-triazole (BTTZ)30 % (18g), KNO 3 50% (30g), Fe 2 o 3 2% (1.2g), CuO2% (1.2g), NaHCO 3 14% (8.4g) and rosin 2% (1.2g);

[0043] A preparation method of pyrotechnic gas generating agent is as follows:

[0044] Step 1. Put the KNO 3 Ball milled in a ball mill at 200r / min for 35min; put BTTZ in a quartz mortar and grind for 20min, and grind the KNO 3 and BTTZ are placed in a desiccator for drying; the dried KNO 3 and BTTZ were passed through a 100-mesh sieve, and the sieve was repeated 3 times to obtain KNO with a particle size of ≤0.15mm 3 And BTTZ with particle size ≤0.15mm;

[0045] Step 2. KNO with particle size ≤ 0.15mm 3 , BTTZ, Fe with particle size ≤0.15mm 2 o 3 , CuO and NaHCO 3 After fully mixing, pass through a 50-mesh sieve, and repeat the sieve 3 times to obtain a uniformly mixed powder; add 60 mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com