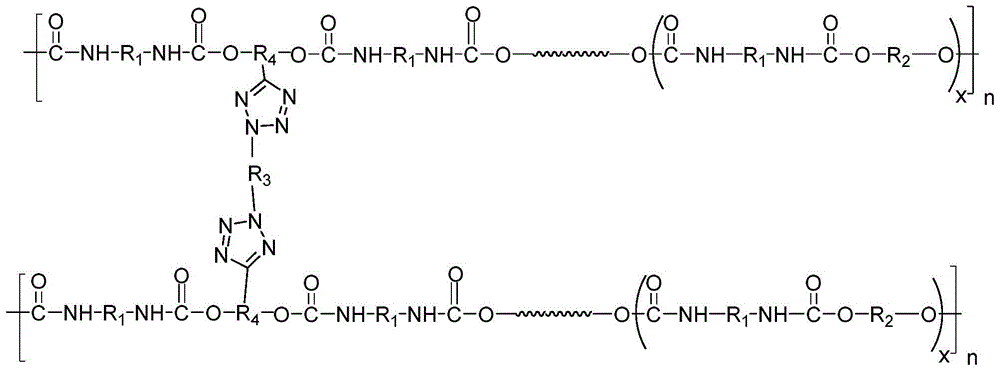

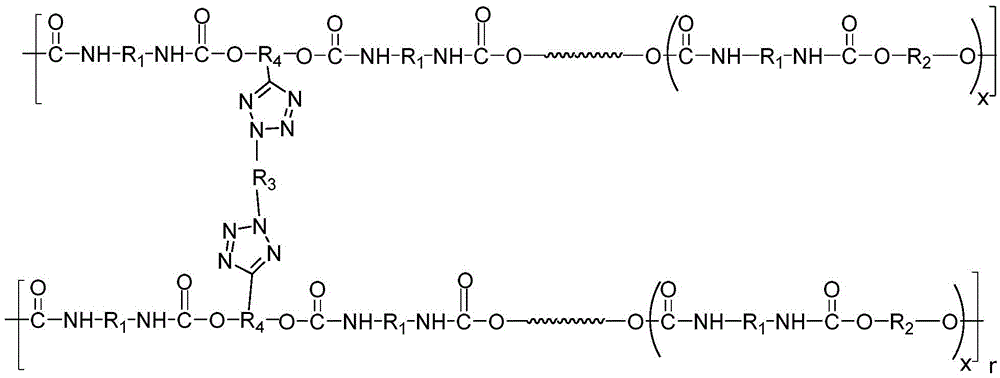

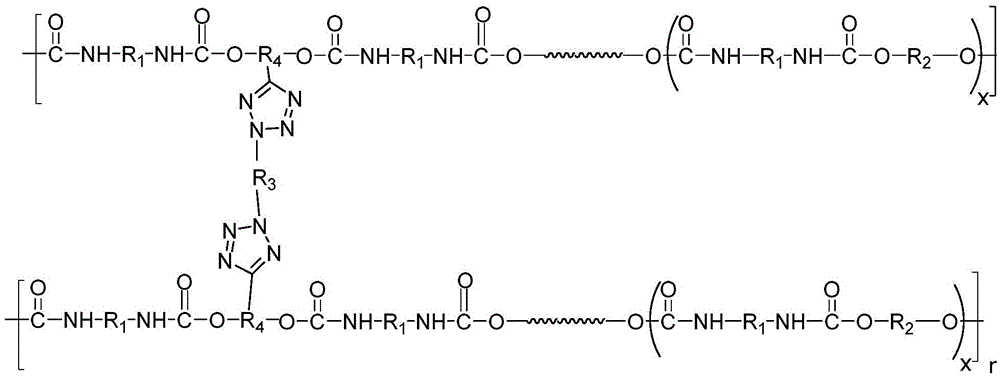

Thermoplastic polyurethane elastomer containing cyano in soft segment and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of polyurethane elastomer preparation, can solve the problems of harsh storage conditions of masterbatch, and achieve the effects of low compression set, excellent mechanical properties and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] will structure as a = 1, b = 10, y = 2 0.1mol of hydroxyl-terminated polybutadiene acrylonitrile, mixed with 10mol of polyadipate-1,4-butylene glycol ester to form hydroxyl-terminated polybutadiene acrylonitrile molar content 1% premix.

[0045] Then take 65 parts by weight of the premix and mix it with 30 parts by weight of benzhydrylmethane-4,4'diisocyanate and 5 parts by weight of 1,4-butanediol, and then inject the resulting mixture into a heated twin-screw extruder. Exit. The temperature of the screw is 150° C., and the rotational speed of the screw is 150 rpm; the reactants are extruded and granulated to obtain a thermoplastic polyurethane elastomer body with cyano groups.

[0046] The thermoplastic polyurethane elastomer body containing cyano group, 4,4'-biphenyl azide with 50% mole of hydroxyl-terminated polybutadiene acrylonitrile, and 50% mole of 4,4'-biphenyl azide ammonium chloride. Compounds containing bis-azido functional groups have a melting point o...

Embodiment 2

[0051] will structure as a=3, b=6, y=3, 5 mol of hydroxyl-terminated polybutadiene acrylonitrile, and 10 mol of polytetrahydrofuran to form a premix with a content of 50% of hydroxyl-terminated polybutadiene acrylonitrile.

[0052] Then 40 parts by weight of the premix was mixed with 45 parts by weight of benzhydrylmethane-4,4'diisocyanate, 15 parts by weight of ethylene glycol, and the resulting mixture was injected into a heated twin-screw extruder. The temperature of the screw is 220° C., and the rotational speed of the screw is 300 rpm; the reactants are extruded and granulated to obtain a thermoplastic polyurethane elastomer body with cyano groups.

[0053] The thermoplastic polyurethane elastomer body containing cyano group, 4,4'-biphenyl azide with 5 mole percent of hydroxyl-terminated polybutadiene acrylonitrile, and 100 mole percent of 4,4'-biphenyl azide Ammonium chloride, the melting point of the compound containing bis-azido functional group is less than 200°C, a...

Embodiment 3

[0059] will structure as a = 10, b = 10, y = 10 2.5mol hydroxyl-terminated polybutadiene acrylonitrile, 5mol tetrahydrofuran hydroxyl-terminated, 5 polyadipate-1,4-butylene glycol ester diol, composed of hydroxyl-terminated poly Premix with 25% butadiene acrylonitrile content.

[0060] Then 50 parts by weight of the premix are mixed with 40 parts by weight of benzhydrylmethane-4,4' diisocyanate, 10 parts by weight of 1,4-butanediol, and the resulting mixture is injected into a heated twin-screw extruder . The temperature of the screw is 200° C., and the rotational speed of the screw is 200 rpm; the reactants are extruded and granulated to obtain a thermoplastic polyurethane elastomer body with cyano groups.

[0061] The thermoplastic polyurethane elastomer body containing cyano group, 4,4'-biphenyl azide with 25% mole of hydroxyl-terminated polybutadiene acrylonitrile, 4,4'-biphenyl azide with 80% mole Ammonium chloride, the melting point of the compound containing bis-azi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com