Method for improving low-temperature anti-freezing characteristic of special-grade palm oil

A palm oil and super-grade technology, applied in the direction of edible oil/fat, producing fat, using additives to preserve fatty substances, etc., can solve the problems of reducing growth rate, improve quality, broaden the application range, and solve the effect of oil crystallization and easy freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

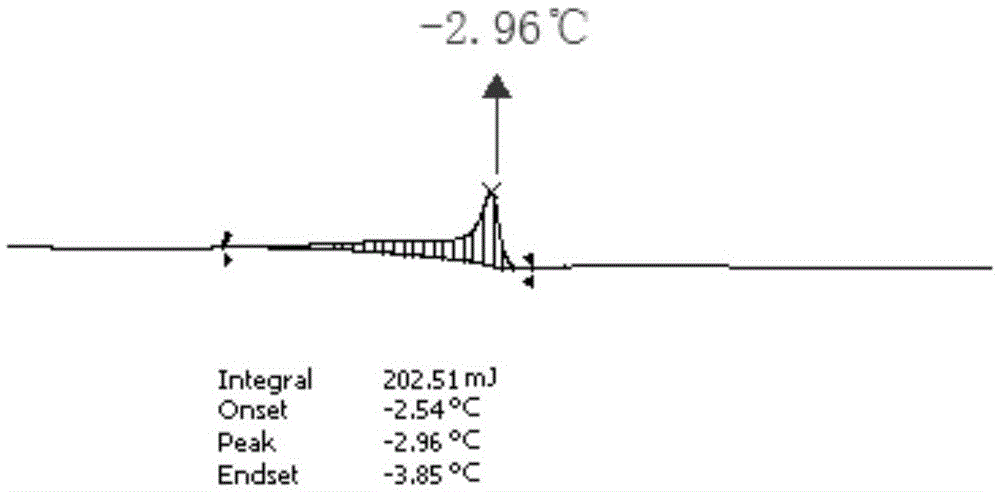

Embodiment 1

[0027] The dry fractionation and crystallization technology is used to improve the iodine value of palm oil products and the method of adding crystallization inhibitor diglyceride to prepare super-grade palm oil products with improved antifreeze performance at low temperature.

[0028] First of all, the iodine value of the palm oil product is increased to 67.05 by using dry fractionation and crystallization technology, and the steps are as follows:

[0029] (1) Heat 100 g of palm oil with an iodine value of 59 to a temperature of 80° C. under stirring, so that all the crystals therein are dissolved, then cool down to -5° C. at a cooling rate of 0.2° C. / min, and grow crystals at a constant temperature for 60 minutes; Then raise the temperature to 5°C at a rate of 0.2°C / min and keep the temperature constant for 60 minutes; then cool down to -5°C at a rate of 0.2°C / min and keep the temperature constant for 60 minutes.

[0030] (2) transfer the grease obtained in step (1) into a s...

Embodiment 2

[0034] The dry fractionation and crystallization technology is used to improve the iodine value of palm oil products and the method of adding crystallization inhibitor diglyceride to prepare super-grade palm oil products with improved antifreeze performance at low temperature.

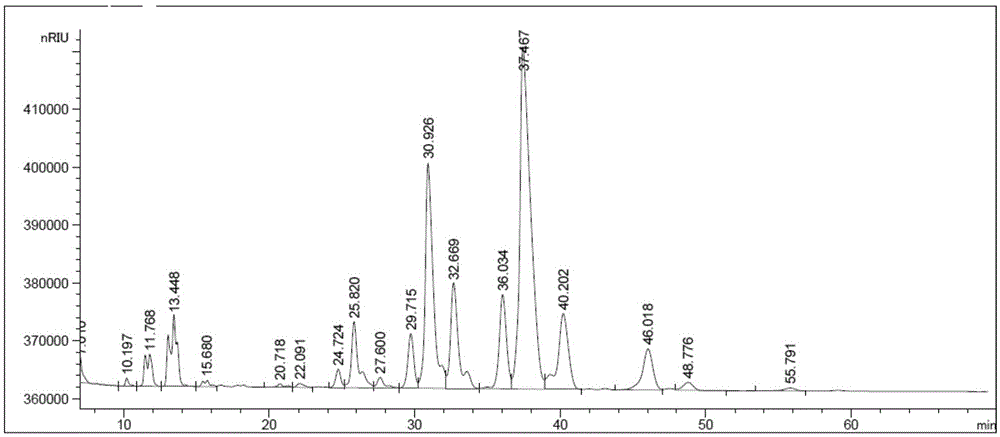

[0035] First, the crystallization inhibitor diglyceride was prepared by column chromatography separation method: 50 g of silica gel was mixed with 200 g of petroleum ether, fully stirred and added to the chromatographic column, and petroleum ether was continuously added to the chromatographic column until the liquid level exceeded the silica gel by 1 cm. Dissolve 100g of palm oil with an iodine value of 59 in 200ml of petroleum ether, and add it to the chromatographic column through a separatory funnel after fully dissolving. After all the petroleum ether solution of palm oil has been added, slowly add 1000ml triglyceride eluent (petroleum ether / ether=95:5v / v), and then add 1000ml diglyceride eluent (pe...

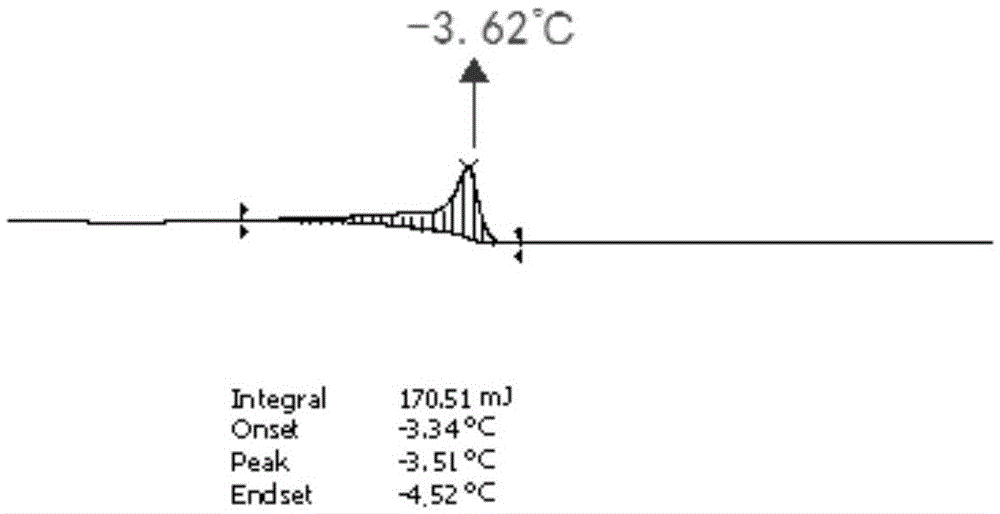

Embodiment 3

[0041] The dry fractionation and crystallization technology is used to improve the iodine value of palm oil products and the method of adding crystallization inhibitor diglyceride to prepare super-grade palm oil products with improved antifreeze performance at low temperature.

[0042] First, the iodine value of the palm oil product is increased to 72.38 by using the dry method fractionation and crystallization technology, and the steps are as follows:

[0043] (1) Heat 100 g of palm oil with an iodine value of 61 to a temperature of 80° C. under stirring, so that all crystals therein are dissolved, then cool down to -7° C. at a cooling rate of 2° C. / min, and grow crystals at a constant temperature for 30 minutes; Then raise the temperature to 2°C at a rate of 2°C / min and keep the temperature constant for 30 minutes; then cool down to -7°C at a rate of 2°C / min and keep the temperature constant for 30 minutes.

[0044] (2) Transfer the grease obtained in step (1) into a separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com