A method for removing arsenic from high-arsenic materials to recover valuable metals therein

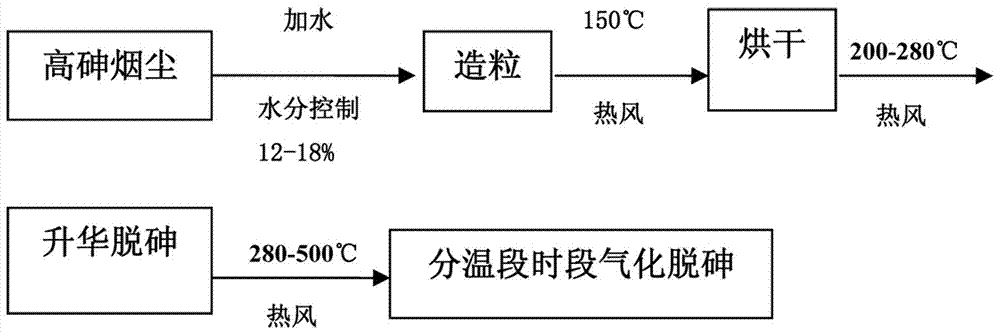

A valuable metal and arsenic removal technology is applied in the field of removing arsenic from high-arsenic materials to recover valuable metals. It can solve the problems of low separation rate of valuable metals, diameter shrinkage, and difficult operation, and achieve reliable process methods, High arsenic removal productivity and effect of improving arsenic removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: utilize horse boiling furnace to implement

[0016] 1) Take 500g of high-arsenic dust, the composition of which is pb10%, sb25%, Bi1%, Sn0.5%, As 2 o 3 35%, H 2 03%; 2) Spray 70g of water in the material tray with high arsenic smoke and granulate with artificial shaking; 3) Select 100g of high arsenic smoke and dust pellets with a particle diameter of 3-6mm and add them to a horse boiling furnace, adjust the furnace temperature to 150°C, and bake Dry for 20 minutes to obtain high-arsenic soot dry material 100-14.9=85.1g; 4) Increase the temperature of the horse boiler to 280°C for 120 minutes until no smoke is seen; 5) Sampling and determination of residual arsenic in the high-arsenic soot pellets After dropping to 15-20%, adjust the temperature of the boiling furnace to 320°C, and wait for no smoke after 25 minutes; 6) adjust the temperature of the boiling furnace to 380°C, and wait for no smoke after 25 minutes; 7) adjust the temperature of the boili...

Embodiment 2

[0017] Embodiment two: Utilize hot blast shaft furnace to implement

[0018] 1) Take 10kg of high-arsenic dust, the composition of the high-arsenic dust: Pb5%, Sb28%, Sn0.8%, As 2 o 3 40%, H 2 O2%, 2) Spray 1.4kg of water in the material tray with high arsenic smoke and granulate with artificial shaking; 3) Select 4 kg of high arsenic smoke and dust granules with a particle diameter of 3-6mm and pack them into a grid sieve with a diameter of Φ100mm at the bottom In the heat-insulating iron pipe used for leak-proofing, the height of the material column is H = 283mm, and the bulk specific gravity of the pellets is 1.8; 4) The hot air with a temperature of 150°C and a flow rate of 500l / min is passed for 80 minutes to dry the water; 5) The Heat the hot air to 280°C, with an air volume of 500 l / min, for 120 minutes; 6) Sampling and measuring the amount of residual arsenic in the high-arsenic soot pellets drops to 15-20%, then raise the temperature of the hot air to 310°C, and mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com