Growth method for improving quality of AlN thin film crystal

A growth method and technology for thin film crystals, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems affecting the performance of AlGaN-based ultraviolet electrical devices, high thermal mismatch and lattice mismatch, easy to generate dislocations and crystals. In order to achieve the effect of promoting step flow growth, improving crystal quality, and increasing nucleation size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

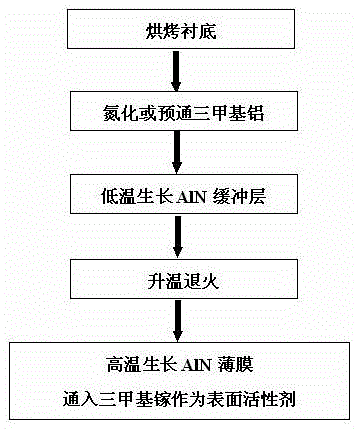

[0035] The AlN film is grown according to the following steps, and the AlN film is grown at a high temperature and fed with trimethylgallium:

[0036] 1) Set the reaction chamber pressure to 150mbar, the reaction chamber temperature to 1100°C, and bake the sapphire substrate in a hydrogen atmosphere for 10 minutes.

[0037] 2) Lower the temperature to 950°C and pre-pass trimethylaluminum for 10s.

[0038] 3) Reduce the pressure of the reaction chamber to 100 mbar, and raise the temperature to 1000° C. to grow an AlN buffer layer with a growth thickness of 20 nm and a V / III ratio of 1000.

[0039] 4) Reduce the pressure of the reaction chamber to 50 mbar, stop feeding trimethylaluminum, continue feeding ammonia gas, raise the temperature to 1150° C. in 400 seconds, and stabilize for 60 seconds.

[0040] 5) Simultaneously feed trimethylaluminum, trimethylgallium and ammonia gas, the flow rates of trimethylaluminum and trimethylgallium are 25 and 300 sccm respectively, and the f...

Embodiment 2

[0043] The AlN film is grown according to the following steps, and the AlN film is grown at a high temperature and fed with trimethylgallium:

[0044] 1) Set the reaction chamber pressure to 150mbar, the reaction chamber temperature to 1100°C, and bake the sapphire substrate in a hydrogen atmosphere for 10 minutes.

[0045] 2) Lower the temperature to 950°C and pre-pass trimethylaluminum for 10s.

[0046] 3) Reduce the pressure of the reaction chamber to 100 mbar, and raise the temperature to 1000° C. to grow an AlN buffer layer with a growth thickness of 20 nm and a V / III ratio of 1000.

[0047] 4) Reduce the pressure of the reaction chamber to 50 mbar, stop feeding trimethylaluminum, continue feeding ammonia gas, raise the temperature to 1150° C. in 400 seconds, and stabilize for 60 seconds.

[0048] 5) Simultaneously feed trimethylaluminum, trimethylgallium and ammonia gas, the flow rates of trimethylaluminum and trimethylgallium are 2.5 and 300 sccm respectively, and the ...

Embodiment 3

[0050] The AlN film is grown according to the following steps, and the AlN film is grown at a high temperature and fed with trimethylgallium:

[0051]1) Set the reaction chamber pressure to 150mbar, the reaction chamber temperature to 1100°C, and bake the sapphire substrate in a hydrogen atmosphere for 10 minutes.

[0052] 2) Lower the temperature to 950°C and pre-pass trimethylaluminum for 10s.

[0053] 3) Reduce the pressure of the reaction chamber to 100 mbar, and raise the temperature to 1000° C. to grow an AlN buffer layer with a growth thickness of 20 nm and a V / III ratio of 1000.

[0054] 4) Reduce the pressure of the reaction chamber to 50 mbar, stop feeding trimethylaluminum, continue feeding ammonia gas, raise the temperature to 1150° C. in 400 seconds, and stabilize for 60 seconds.

[0055] 5) Simultaneously feed trimethylaluminum, trimethylgallium and ammonia gas, the flow rates of trimethylaluminum and trimethylgallium are 12.5 and 300 sccm respectively, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com