Preparation method for fluorescent spandex utilizing spandex waste fiber as raw material

A technology of spandex and fluorescence, which is applied in the manufacture of rayon, single-component synthetic polymer rayon, and fiber chemical characteristics, can solve problems such as agglomeration, increase the degree of bonding, strong fluorescent activity, and increase the degree of graft polymerization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

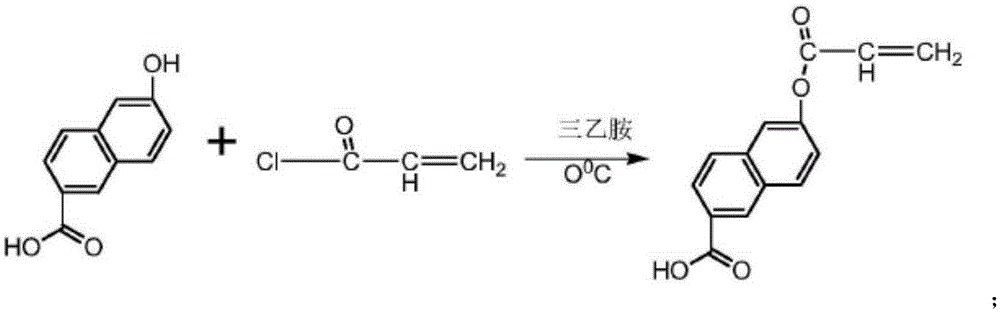

[0028] (1) Preparation of intermediate monomers

[0029] Add 2 mol of 6-hydroxy-2-naphthoic acid and 2.4 mol of catalyst triethylamine into 80 ml of dichloromethane solvent, stir evenly in an ice bath, then add 2.8 mol of acryloyl chloride dropwise to the solvent for 2 hours Completed, after 15 hours of reaction in ice bath, wash with dilute hydrochloric acid with a solute mass fraction of 20%, then deionized water, dry over anhydrous magnesium sulfate, and spin evaporate to obtain the reaction product, which is the naphthalene containing double bond Formic acid monomer, the intermediate monomer required by the present invention,

[0030] The approximate reaction equation of above-mentioned steps (1) is

[0031]

[0032] (2) Preparation of photoinitiator-loaded spandex

[0033] A. In the prepolymerization tank, first add DMAC and PTMG (polytetramethylene ether glycol, molecular weight 1500), and then add 4,4-MDI (4,4- Diphenylmethane diisocyanate), warming up to 50°C, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com