Flame-retardant wool fabric finishing method

A flame retardant finishing and fabric technology, applied in the direction of enzyme/microbe biochemical treatment, flame retardant fiber, fiber treatment, etc., can solve the problems of easy decrease in whiteness of fiber products, unfavorable industrialization promotion, complicated treatment process, etc., and achieve whiteness The effect of small impact on speed and hand feeling, low loss, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for flame-retardant finishing of wool fabrics, comprising the following steps:

[0044] The first step: sodium dihydrogen phosphate solution pretreatment:

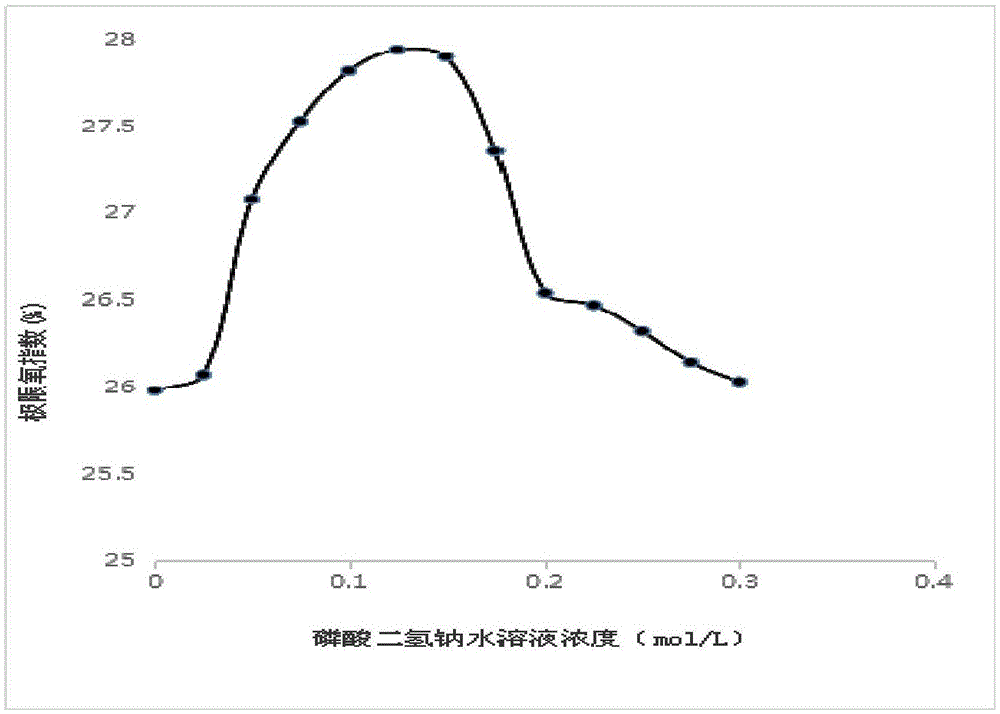

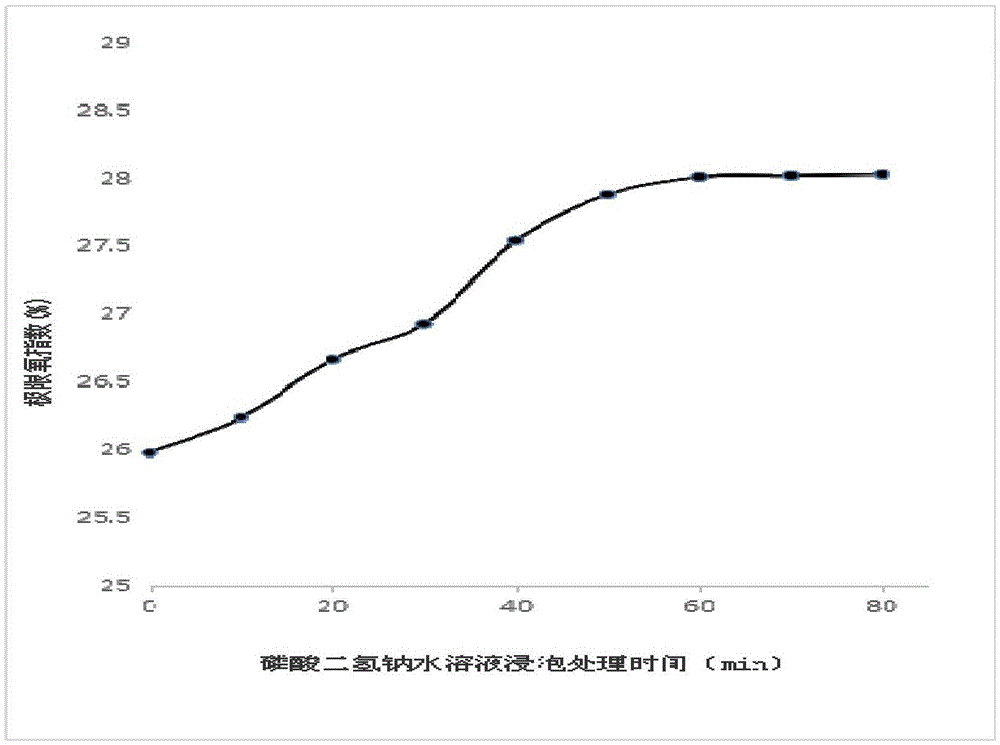

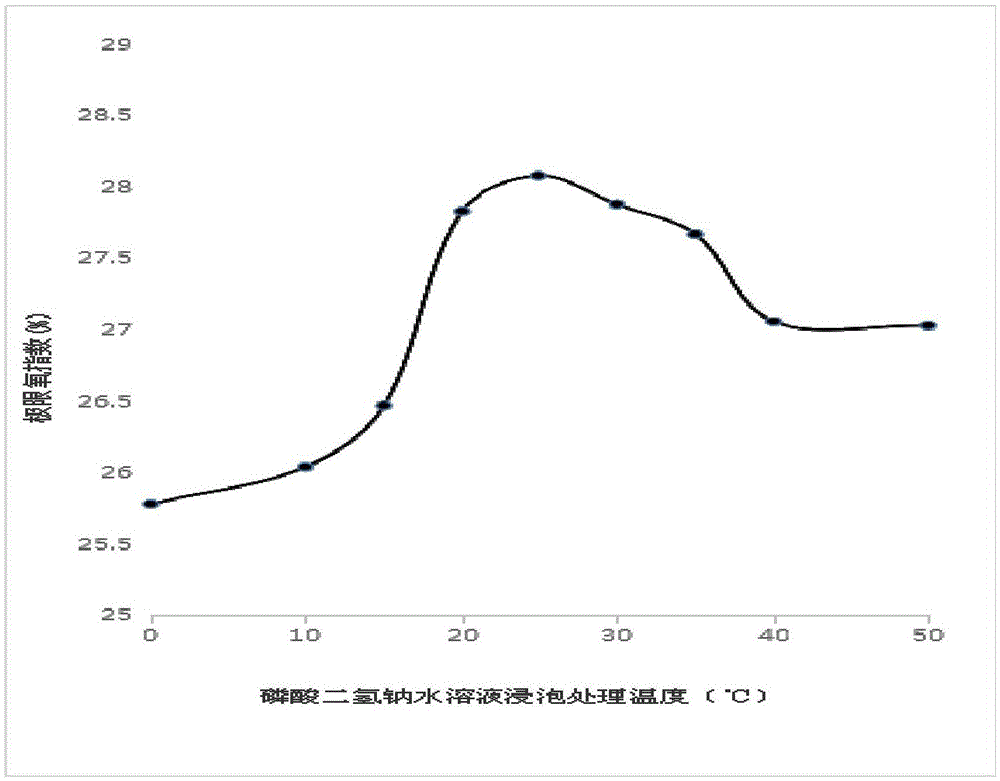

[0045] Soak the woolen fabric in an aqueous solution of sodium dihydrogen phosphate with a concentration of 0.1mol / L for 50 minutes, the bath ratio is 1:20, and the soaking temperature is 20°C; pretreatment with the sodium dihydrogen phosphate solution is followed by washing and drying;

[0046] Among them, wash twice with water, and the drying temperature is 50°C;

[0047] The second step: protease pretreatment:

[0048] Soak the woolen fabric in a mixed protein enzyme water solution with a concentration of 1% for 10 minutes, the soaking temperature is 50°C, and the bath ratio is 1:20; after the protease pretreatment, it is washed and dried;

[0049] Wherein, the mixed protease is composed of ficin, pronase and bromelain mixed in a weight ratio of 1:2:1;

[0050] Wash once with water and dry at 70°C;

...

Embodiment 2

[0055] A method for flame-retardant finishing of wool fabrics, comprising the following steps:

[0056] The first step: sodium dihydrogen phosphate solution pretreatment:

[0057] Soak the woolen fabric in 0.15mol / L sodium dihydrogen phosphate aqueous solution for 70 minutes, the bath ratio is 1:20, and the soaking temperature is 25°C; after pretreatment with sodium dihydrogen phosphate solution, wash and dry;

[0058] Among them, washing 3 times, drying temperature is 60 ℃;

[0059] The second step: protease pretreatment:

[0060] Soak the woolen fabric in a 1.5% mixed protein enzyme water solution for 15 minutes, the soaking temperature is 60°C, and the bath ratio is 1:30; after the protease pretreatment, it is washed and dried;

[0061] Wherein, the mixed protease is composed of ficin, pronase and bromelain mixed in a weight ratio of 1:3:2;

[0062] Wash twice with water and dry at 75°C;

[0063] The third step: protease modification treatment:

[0064] Put the wool fa...

Embodiment 3

[0067] A method for flame-retardant finishing of wool fabrics, comprising the following steps:

[0068] The first step: sodium dihydrogen phosphate solution pretreatment:

[0069] Soak the woolen fabric in a 0.1mol / L sodium dihydrogen phosphate aqueous solution for 70 minutes, the bath ratio is 1:20, and the soaking temperature is 20°C; after pretreatment with the sodium dihydrogen phosphate solution, wash and dry;

[0070] Among them, washing 3 times with water, drying temperature is 50 ℃;

[0071] The second step: protease pretreatment:

[0072] Soak the woolen fabric in a mixed protein enzyme water solution with a concentration of 1% for 15 minutes, the soaking temperature is 50°C, and the bath ratio is 1:30; after the protease pretreatment, it is washed and dried;

[0073] Wherein, the mixed protease is composed of ficin, pronase and bromelain mixed in a weight ratio of 1:2:2;

[0074] Wash once with water and dry at 75°C;

[0075] The third step: protease modification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com