Automatic device for measuring sulfur dioxide capacity of active coke with continuous method

A sulfur dioxide and activated coke technology, applied in the direction of material electrochemical variables, can solve the problems of complex and bulky heating devices, low integration of detection systems, lack of flue gas preheating systems, etc., and achieve precise control of water vapor flow and quantitative accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following are examples of the present invention, which are only used to explain the present invention rather than limit it.

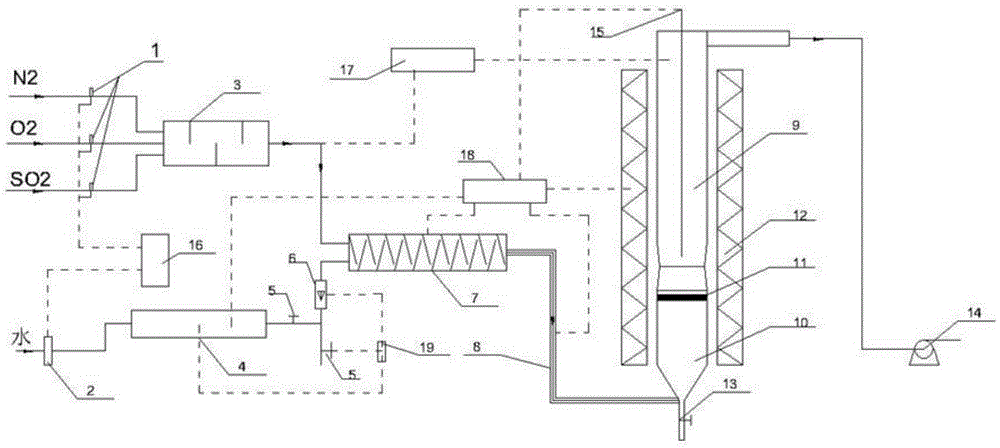

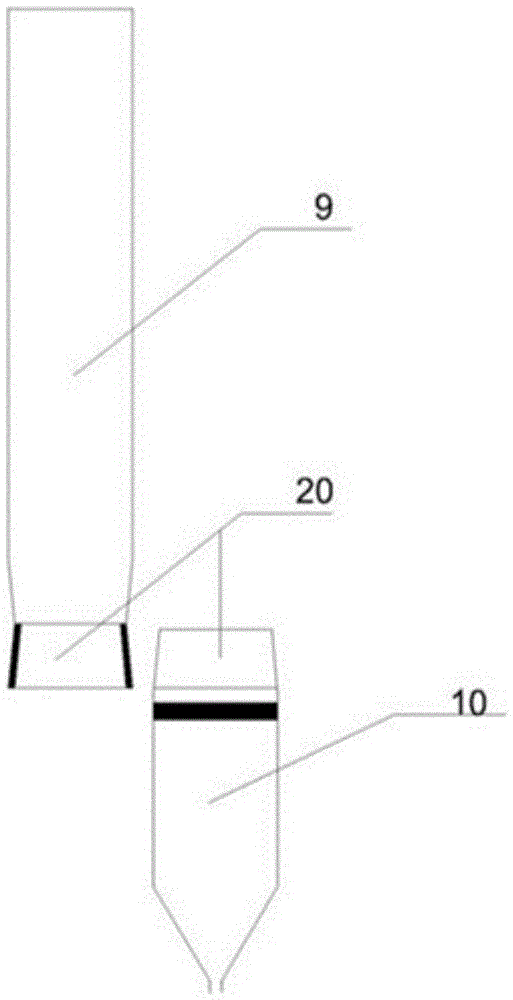

[0046] see figure 1 and figure 2 , an automatic device for continuously measuring the sulfur dioxide capacity of active coke mainly includes: mass flowmeter 1, peristaltic pump 2, premixer 3, gasifier 4, solenoid valve 5, high-temperature rotameter 6, heating mixer 7 , heating sleeve 8, upper reaction tube 9, lower reaction tube 10, distribution plate 11, gold-plated resistance wire furnace 12, ash discharge valve 13, vacuum pump 14, thermocouple 15, flow controller 16, gas detector 17, temperature control 18, feedback regulator 19, and grinding interface 20; the connection method is: nitrogen, oxygen, and sulfur dioxide are accurately quantified by the mass flow meter 1 and then enter the premixer 3 for preliminary mixing; water is accurately quantified by the peristaltic pump 2 and then enters the air The carburetor 4 is gasified to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com