Method for analyzing content and distribution of Cr in Cr-doped zinc sulfide crystalline material

A crystal material, zinc sulfide technology, applied in the field of analytical chemistry, can solve the problems of unavailability, easy pollution, tedious and time-consuming, etc., achieve accurate quantitative analysis, high sensitivity, and avoid the effect of sample pretreatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

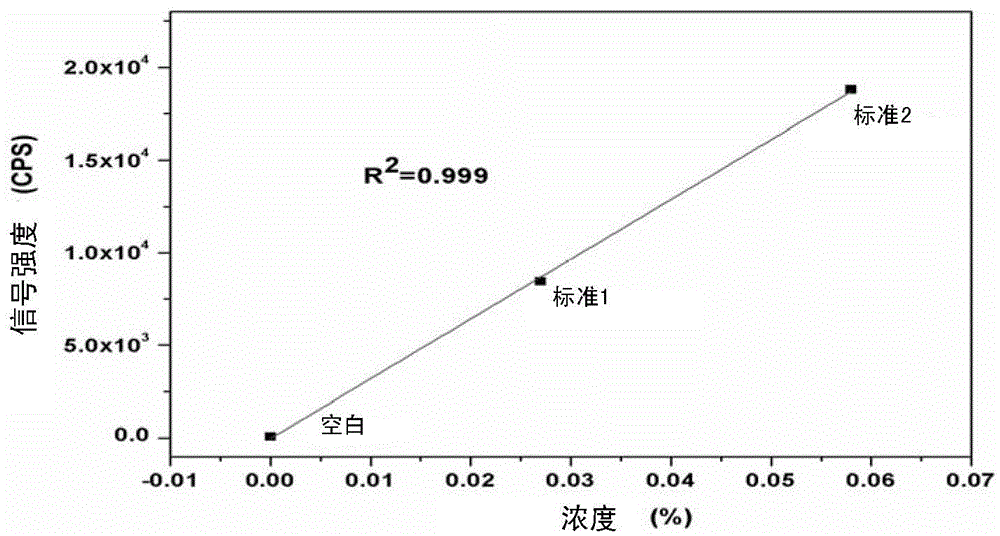

[0024] Regarding the preparation of solid standard substances, the ZnS matrix material can be grown by vapor deposition, and the surface of the ZnS matrix material can be plated with a uniform thickness and dense Cr film by the magnetic filtration ion plating method. The ZnS matrix material plated with Cr film is diffused at 950° C. for more than 14 days in the tube, and it is obtained by grinding and polishing after the diffusion is completed. Specifically, the above preparation method refers to FangZhenyietal (FangZhenyi, ChaiYichao, HaoYongliang, YangYaoyuan, DongYanping, YanZewu, TianHongchang, XiaoHongtao, WangHeming.JournalofCrystalGrowth, 2002, 237-239:1707-1710), A.F.Shchurov. Ikonnikov, E.V.Yashina, A.N.Sysoev, D.N.Shevarenkov. Inorganic Materials, 2004, 40(4):336–339), Zhu Tufu et al (Zhu Tufu, Shen Liru, Xu Guidong, Jin Fanya. China Surface Engineering, 2008, 4( 21): 27-35) and other methods. In the solid standard substance, there is the following relationship betw...

Embodiment 1

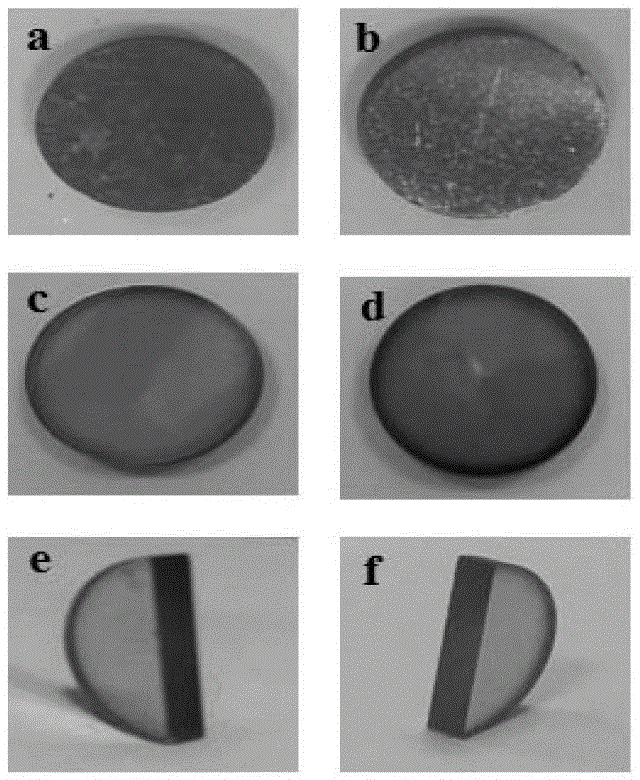

[0037] (1) Preparation of Cr:ZnS solid standard substance

[0038] Solid standard substances were prepared by thermal diffusion method. The preparation steps include: first growing a ZnS matrix material by a vapor deposition (CVD) method, and then plating a uniform and dense Cr film on the surface of the ZnS matrix by using a magnetic filter ion plating (FAD) method. The material is then encapsulated in vacuum quartz tubes (-1 Pa), diffused at a high temperature of 950°C for more than 2 weeks to obtain a uniformly doped crystal material. Polishing is performed after the diffusion process.

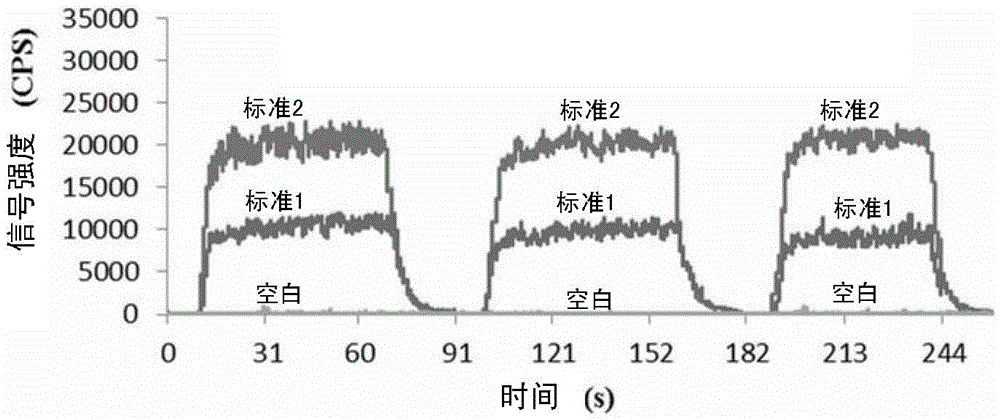

[0039] (2) LA-ICP-MS instrument parameters and joint analysis

[0040] The optimized instrument parameters are as follows: laser ablation adopts Cetac213nm Nd:YAG laser sampling system, laser wavelength is 213nm, laser energy is 50%, laser frequency is 10Hz, laser beam spot is 1000μm, scan rate is 50μm / s, helium gas flow rate is 0.6L / min; ICP-MS is a ThermoXseries II CCT quadrupole, arg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com