Three-phase inverter drive method and device employing SPWM control

A technology of a three-phase inverter and a driving method, which is applied in the direction of output power conversion device, conversion of AC power input to DC power output, high-efficiency power electronic conversion, etc. In order to reduce the risk of thermal damage and IGBT gate breakdown, reduce the loss of the drive circuit, and improve the efficiency of the inverter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present application are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the invention, and are not intended to limit the scope of the present invention.

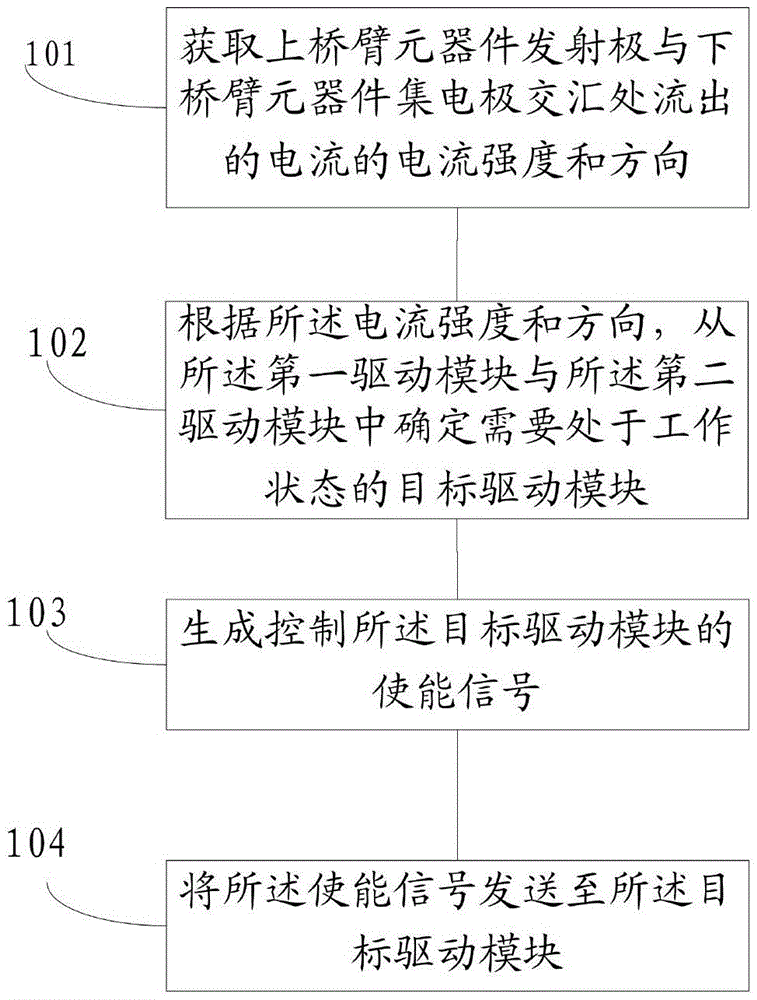

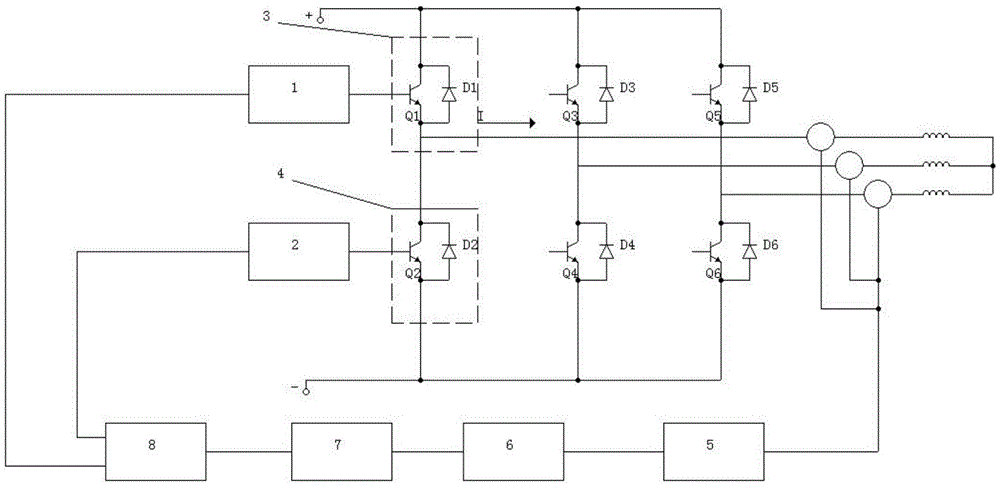

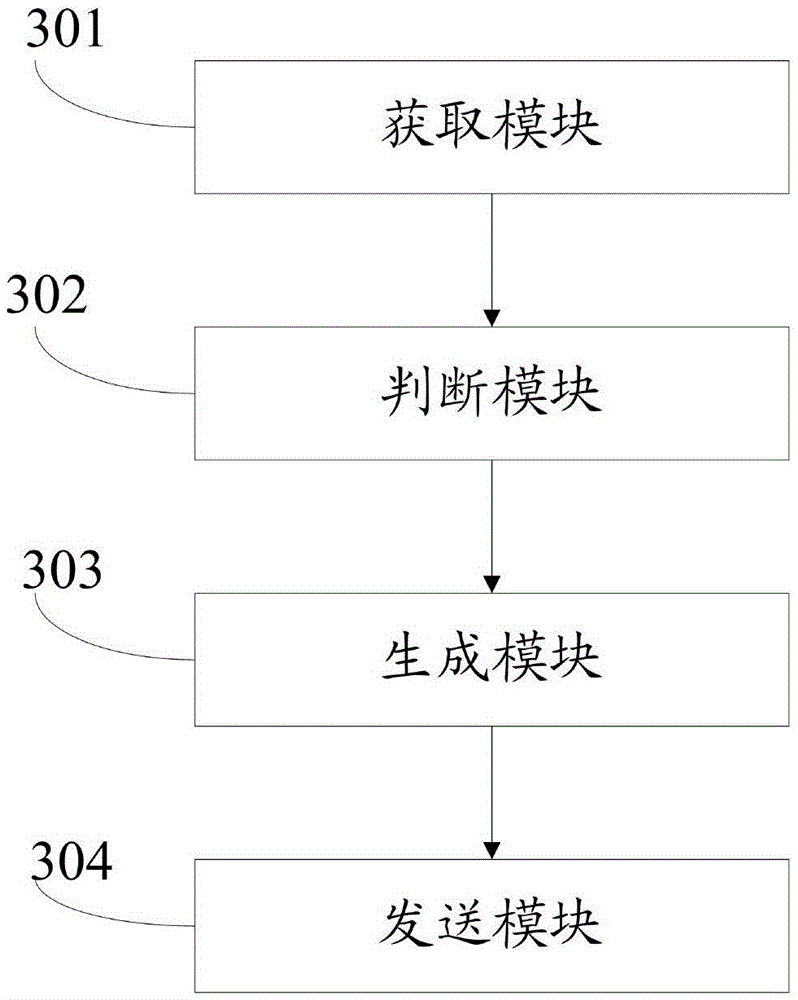

[0033] A three-phase inverter driving method controlled by SPWM is characterized in that, the three-phase inverter specifically includes: an upper bridge arm, a lower bridge arm, a first drive module, and a second drive module; the upper bridge arm The lower bridge arm has the same three-phase semiconductor power switching device, and the upper bridge arm is connected in the same way as the three-phase semiconductor power switching device of the lower bridge arm; the first drive module is connected to the upper bridge arm The control pole of the switching device of the arm is connected, the second drive module is connected with the control pole of the switching device of the lower bridge arm; the emitter of the upper bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com