Compound flocculant with polymerization ferric chloride and amination polymers based on papermaking sludge and method for preparing compound flocculant

A technology of polyferric chloride and composite flocculant, applied in chemical instruments and methods, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. The problems of narrow range and high operating cost can achieve good coagulation effect, reduce slow stirring and sedimentation time, and high coagulation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

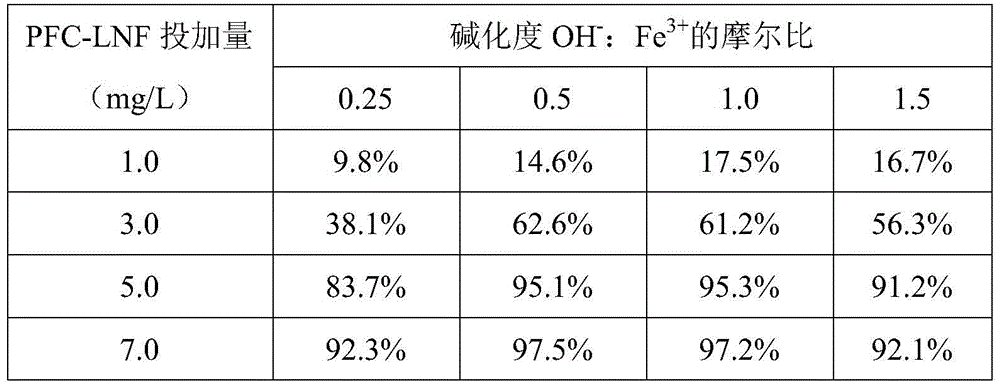

[0051] Embodiment 1. The preparation of the composite flocculant (PFC-LNF) of different alkalization degrees

[0052] (1) Weigh 24.1g of FeCl 3 ·6H 2 0 solid and dissolved in deionized water, adding Na dropwise 2 CO 3 solution, control OH - : Fe 3+ The molar ratio is 0.25, 0.5, 1.0, 1.5, until it is completely dissolved under the action of magnetic stirring. After the foam disappears, add 1.27g of Na stabilizer according to the ratio of phosphorus to iron molar ratio of 0.08 2 HPO 4 12H20 powder, continue to stir until it is completely dissolved, and finally dilute to 500ml with distilled water to obtain a polyferric chloride solution with a mass concentration of Fe of 10g / L;

[0053] (2) Add 2.0 g of papermaking sludge into 50 ml of deionized water, add dropwise 1 mol / L NaOH solution under stirring, control the pH to 11.5, stir at a speed of 200 rpm for 20 min, and centrifuge the obtained mixture for 10 min at a speed of 10000 rpm, take Pour the supernatant into the re...

Embodiment 2

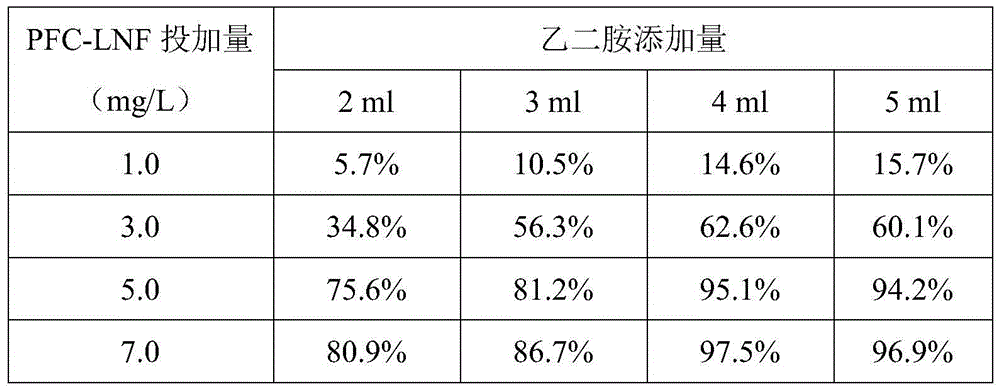

[0055] Embodiment 2. The preparation of the composite flocculant (PFC-LNF) of different ethylenediamine addition amount

[0056] Same as described in Example 1, the difference is that the addition of anhydrous sodium carbonate is 2.4g, and the addition of step (2) ethylenediamine is respectively 2ml, 3ml, 4ml, 5ml, to obtain different additions of ethylenediamine Quantity of composite flocculant products.

Embodiment 3

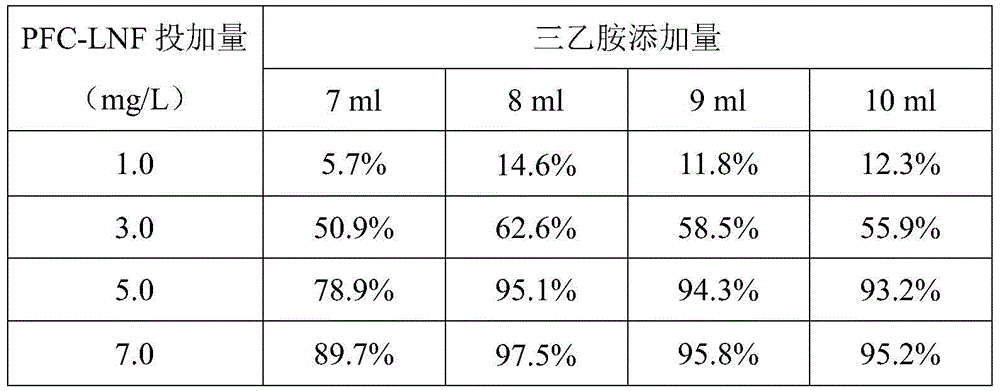

[0057] Embodiment 3. The preparation of the composite flocculant (PFC-LNF) of different triethylamine addition amount

[0058] The same as described in Example 2, the difference is that the addition of ethylenediamine is 4ml, and the addition of triethylamine in step (2) is 7ml, 8ml, 9ml, 10ml respectively, to obtain the composite of different triethylamine additions. flocculant products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com