One-dimensional structure metal-organic framework compound and preparation method thereof

A metal-organic framework and compound technology, applied in the field of one-dimensional structure metal-organic framework compounds and their preparation, can solve the problems of limiting the practical application of metal-organic framework compounds, harsh preparation conditions, complicated preparation procedures, etc., and achieve uniform structure and morphology. The effect of good performance, short reaction time and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 0.06 mol of trimesic acid into 300 mL of deionized water, and heat the solution to 80°C until the trimesic acid is completely dissolved. Take 0.09 mol of copper nitrate and add it to the prepared trimesic acid solution and let it stand for 10 minutes, then use a centrifuge to collect the precipitated precipitate, wash it with deionized water for 3 times, and dry it at 100°C to obtain a one-dimensional Structured CuBTC nanowire material.

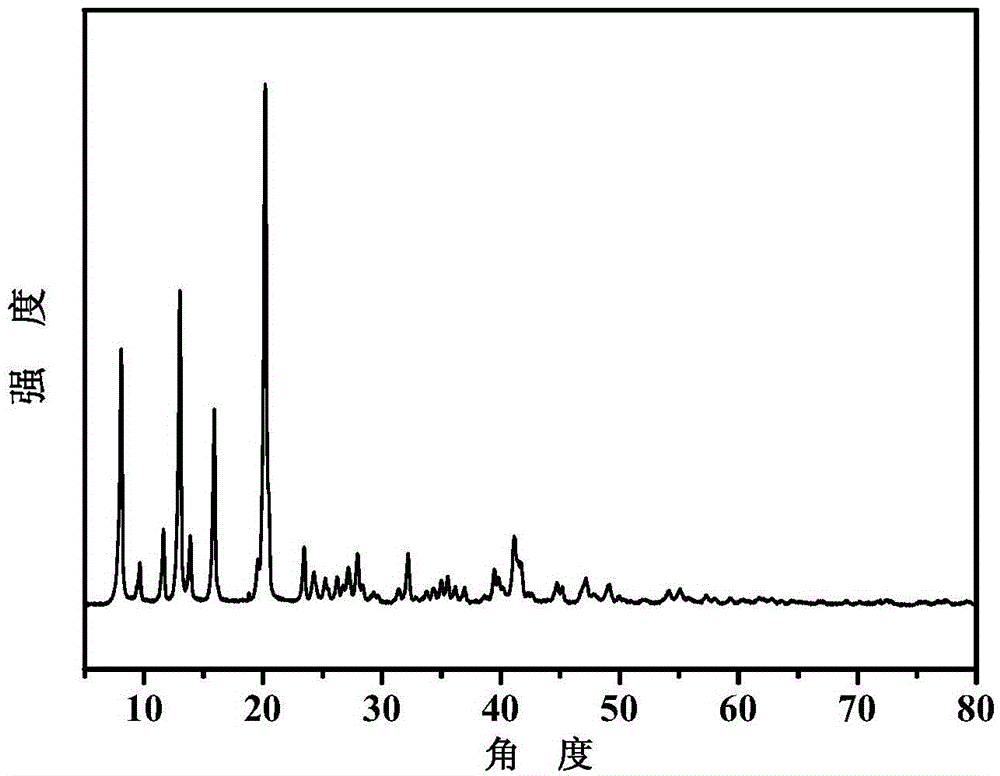

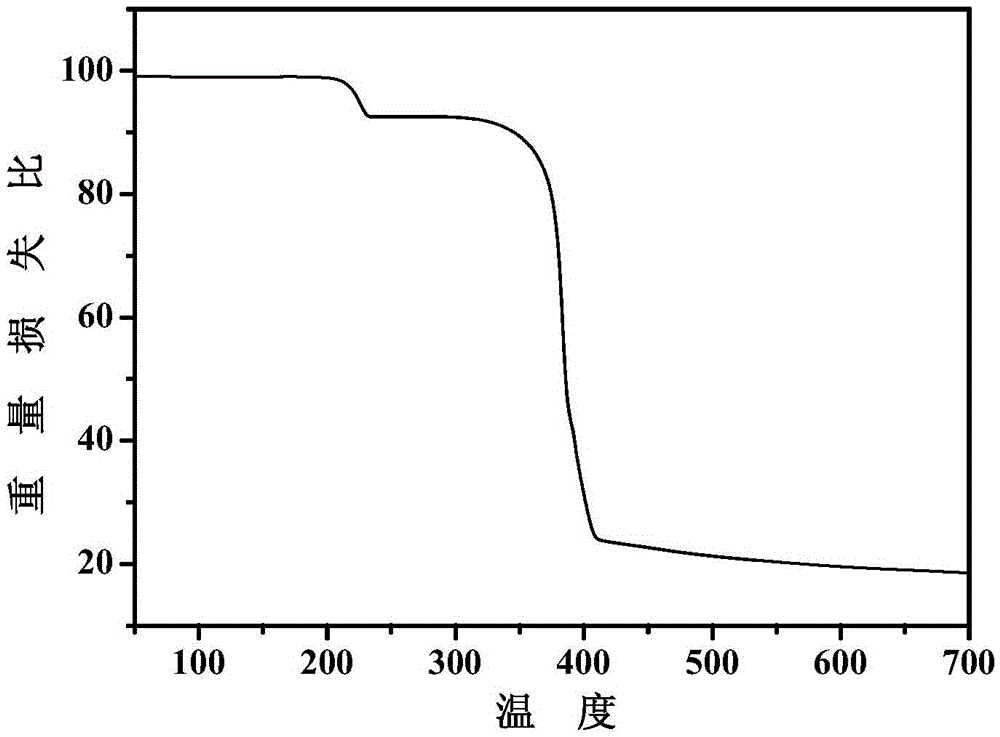

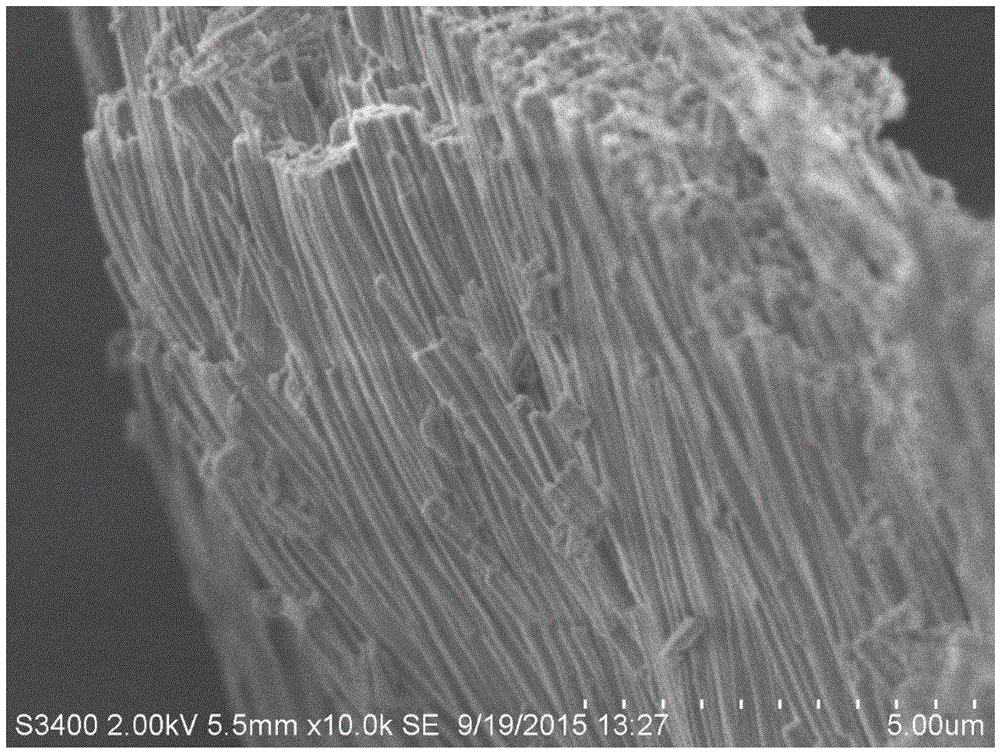

[0046] like Figure 1~4 As shown, the obtained product is characterized by means of X-ray diffraction (XRD), scanning electron microscope (SEM), energy spectrum of X-ray (EDX) and thermogravimetric analysis (TG), and it is confirmed that the product is CuBTC and has a one-dimensional nanowire structure .

[0047] Table 1 X-ray energy spectrum analysis results.

[0048] the element

Embodiment 2

[0050] Take 0.06mol of terephthalic acid and add it to 300mL of ethanol, and heat the solution to 80°C until the terephthalic acid is completely dissolved. Take 0.06 mol ferrous chloride and add it to the prepared terephthalic acid solution and let it stand for 10 minutes, collect the precipitated precipitate by suction filtration, wash it with ethanol centrifuge for 3 times, and then freeze-dry to obtain the one-dimensional structure of FeBDC nanowire material.

[0051]The obtained product was characterized by means of XRD, SEM, EDX and TG, and it was confirmed that the product was FeBDC and had a one-dimensional nanowire structure.

Embodiment 3

[0053] Take 0.06mol of trimesic acid and add it to 500mL of N-methylpyrrolidone, and heat the solution to 70°C until the trimesic acid is completely dissolved. Take 0.09mol of nickel acetate and add it to the prepared trimesic acid solution and let it stand for 30 minutes, then use suction filtration to collect the precipitate, and use N-methylpyrrolidone to centrifugally wash it for 3 times, then use spray drying to obtain a one-dimensional structure NiBTC nanowire material.

[0054] The obtained product was characterized by means of XRD, SEM, EDX and TG, which confirmed that the product was NiBTC and had a one-dimensional nanowire structure.

[0055] The obtained one-dimensional structure NiBTC nanowire material was calcined at 500° C. for 2 h under an inert atmosphere to obtain a carbon-coated nickel oxide nanowire material. It will be discussed that the coated nickel oxide nanowires can be used as anode materials for lithium-ion batteries to obtain excellent electrochemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com